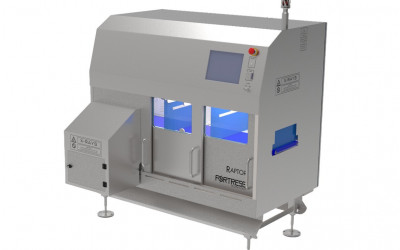

Monitoring Tool IN-SITE CIP optimizes CIP Processes

Why consume more than necessary? Christeyns presents IN-SITE CIP, a smart monitoring solution designed to optimize CIP processes. The IN-SITE CIP software integrates seamlessly with existing PLC systems and collects, ana..

Read more