Digital developments are rapid and bring efficiency. But what technological innovations do food companies need to confidently face the future? How do they know which solution fits their company best and can also ensure product quality? Four suppliers to the food processing and producing industry respond.

Chain integration, sustainability, cost reduction, production automation and enhancement, and controlled quality are six key areas of focus for food companies. They need to innovate in these areas due to the current labor shortage, sharply rising costs, and new legislation and regulations. At the Food Tech Event on May 15 and 16, 2024, in the Brabanthallen in 's-Hertogenbosch, they can explore technological solutions with several experts.

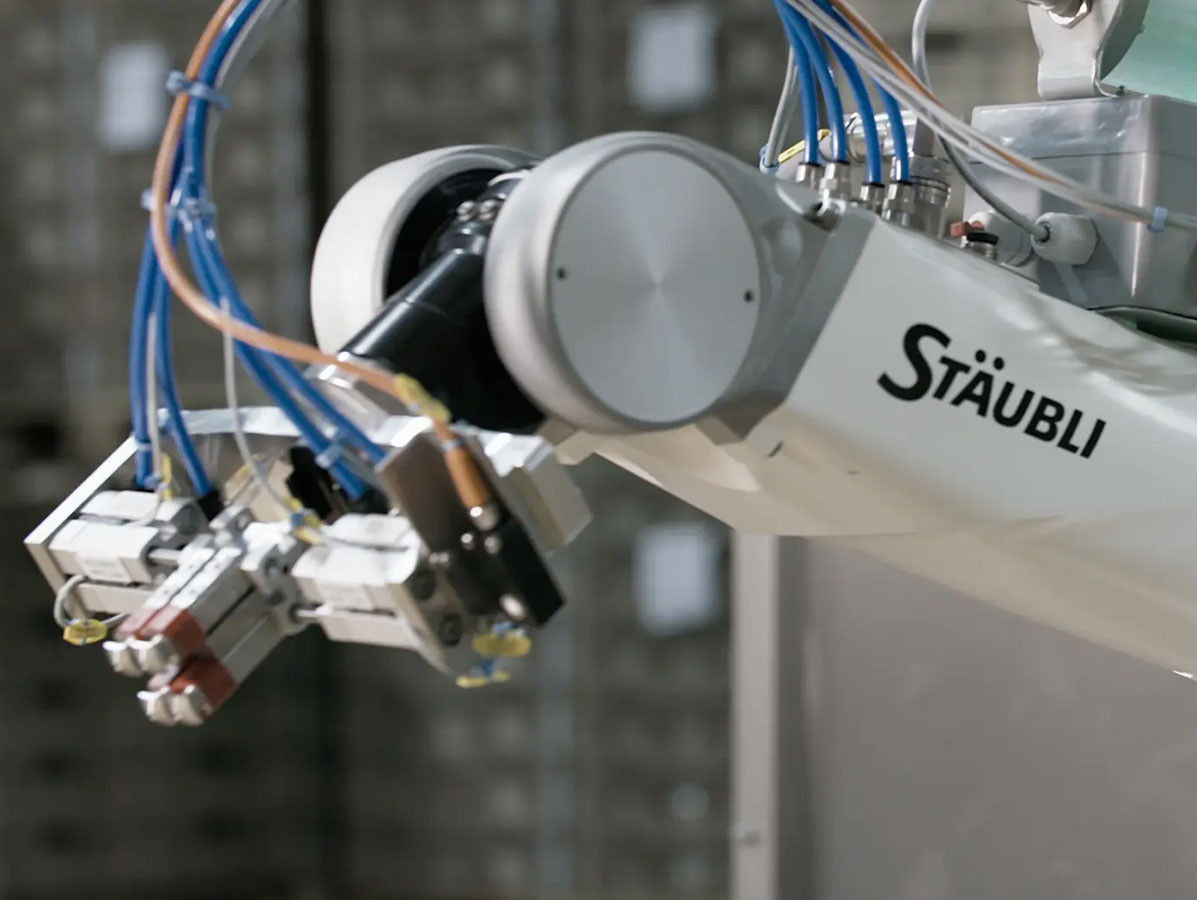

Five experts offer a preview and address the needs they observe in the food sector. Hans de Wit, co-owner of DNA Services B.V., Bram de Vrught, co-owner of QING, Will Uijting, commercial director of QING, Jan Buit, Segment Manager Pharma & Food NL at Staubli, and Joris Kolff, Sr. Director, Strategic Project(s) F&B at Aptean, all specialize in developing and implementing comprehensive, innovative, technological solutions. They understand the bottlenecks, challenges, and solutions.

Joris Kolff kicks off: "The need is broad and triggered by several trends: rising costs, high inflation, uncertainty in raw materials, changing consumer behavior, and sustainability. Companies need to be more agile than before. That means they want to move away from various custom-made, often separate, software solutions. They need a single digital platform as a solid foundation, one that adapts and is always up-to-date."

Hans de Wit recognizes this phenomenon: "We indeed see food companies still often pulling data from multiple systems without any interaction between the different systems. Chain integration is the keyword."

Will Uijting emphasizes that digitalization is not an end in itself. "Production automation must solve certain needs and guarantee a desired quality level. However, companies often hesitate to decide to innovate."

"The time for hesitation is over," Jan Buit adds. "To maintain their competitive position, they need to take steps now. Due to aging, low influx, and high costs, production per employee must increase. That means digitalizing. Robotics and AI will play an important role."

©Stäubli

From the experts' responses, it's clear that many food companies work with outdated systems and multiple software solutions without integration. And that a number of companies still manually process orders, risking incorrect data processing. They hear companies want to modernize and are aware of the necessity but often don't know how. Because what is the first step towards renewal? Which technological solutions are available? For example, how can you automate a production process with organic shapes with varying dimensions, like bell peppers or meat parts? Which system best fits the company? How is progress ensured; production must always continue! What does this mean for the current employees? What are the costs?

Will Uijting: "We engage in conversation and outline two starting approaches: from research; what is company-specific and what solution does that require? And from experience; we see what is needed and can quickly make a digitization leap with our 'standard' applications. We don't think from the existing situation based on machines, we look mainly at what is technologically possible. For example, you can apply AI or Vision for image recognition in the production process."

"That is indeed possible with the previously mentioned bell peppers," Jan Buit adds. "As humans, you see the different sizes. A robot on the production line doesn't see that. With the integration of AI or Vision, that works, then you bring recognition into the process. Such a process is complex. We make these specific robots for food. Where we also pay attention to environmental and high hygiene requirements. The robot must be resistant to cleaning with water and chemical cleaning agents."

Hans de Wit gives another example: "A retailer needed the origin of meat to be visible to the consumer. We solved this by placing a QR code on the packaging in collaboration with the supplier. When the consumer scans that code, they can immediately see where the meat was processed. This is not only about 'tying systems together' but also about transparency and data exchange. It's a complete picture that has to be right."

Joris Kolff values realizing solutions that are right and ensure the core processes of the food company continue. "A solid foundation involves data from the financial department, operations, logistics, and distribution. We can add extra layers, for example, for an OEE report or the introduction of an MES system. With all the data, you can give employees insight and let them steer on real-time data. Additionally, there might be a need to further optimize maintenance with EAM, to prevent machine breakdowns and predict maintenance based on history."

©QING, Forward Engineering

"Automation is necessary to secure business processes. Given the labor shortage, manual work stops," says Hans de Wit and then highlights the advantages of efficiency and job satisfaction: "The tasks of processing purchase invoices - checking, approving, booking - are cumbersome. With our solution, where scan and recognition software is built-in, no longer. The system scans an invoice that appears in the email inbox, recognizes whether it is a purchase invoice, checks if the amount is correct, and can approve the invoice. Only making it payable to the bank does not happen entirely automatically, you don't want to fully automate that."

Jan Buit mentions another practical case with benefits from automation: "We can ensure that in the process of picking orders, photos are taken at certain steps. For example, how a product goes into the truck and how the delivery then took place. The photos serve as proof of transaction in the chain and are automatically archived behind the assignment."

Bram de Vrught also cares about the human aspect: "We must not forget the human aspect. We must take them along in the modernization, create sufficient support to let the automation land well. It's not just about solving problems, but also about having the right people in the company, and helping them with training and support during the integration. Then you're sure the solution continues to add value."

"You indeed can't go from 0 to 100 in five seconds," confirms Joris Kolff. "Making a modernization leap with the company and the people who work there takes time, attention, and a multi-year plan. Due to staff shortages and high turnover, you can no longer always rely on employees knowing the processes. Then automation provides a solution. It also requires forward-looking, so you can already properly set up an ERP system for the challenges that are coming. Technology continues to evolve. The expectation is that within two years, we can ask the ERP system questions about cash flow or inventory."

Aptean focuses on the integrated approach. Joris Kolff: "With examples, we want to give visitors a feel, show that an integrated approach is more efficient than replacing one piece of software and then another part later. They can get acquainted with our expertise and services (ERP, OEE, EAM, MES, PLM) that we deploy to be ready for the future."

DNA Services will display at their stand, among other things, the 'Scan and Recognize' solution for incoming invoice streams. And also applications like Photo-Apps and Track & Trace Apps as examples of customer-specific applications. Hans de Wit: "We are a specialist in providing ERP software, developing customer-specific software, and building API connections. We look at companies to see how we can complete their automation. To further digitize any still manual or repetitive tasks and integrate new options within the application landscape."

Bram de Vrught explains that QING at their stand wants visitors to experience for themselves how to use AI in a user-friendly way. "Thus, we give them confidence to take the necessary innovation steps with us. Just like we do with our lecture on May 15: 'I want Bolletje! But what does Bolletje actually want?' A practical case about how Bolletje and QING collaborate to gain even more control over the production process with a manageable approach."

Staubli launches a new robot setup with AI integration along with QING at the demo square, making it possible to process a product - regardless of changes in the product or environment. Jan Buit: "I love to talk about digitalization, but showing is stronger. Many people read about it, and hesitate against it. They can now experience in practice what it entails."

Source: Vakblad Voedingsindustrie 2024