The pH value is one of the units of measurement used to characterize a food product. Usually, this value is considered simple to measure and is added to the list of analyses to be performed. However, don't be misled: this can be costly!

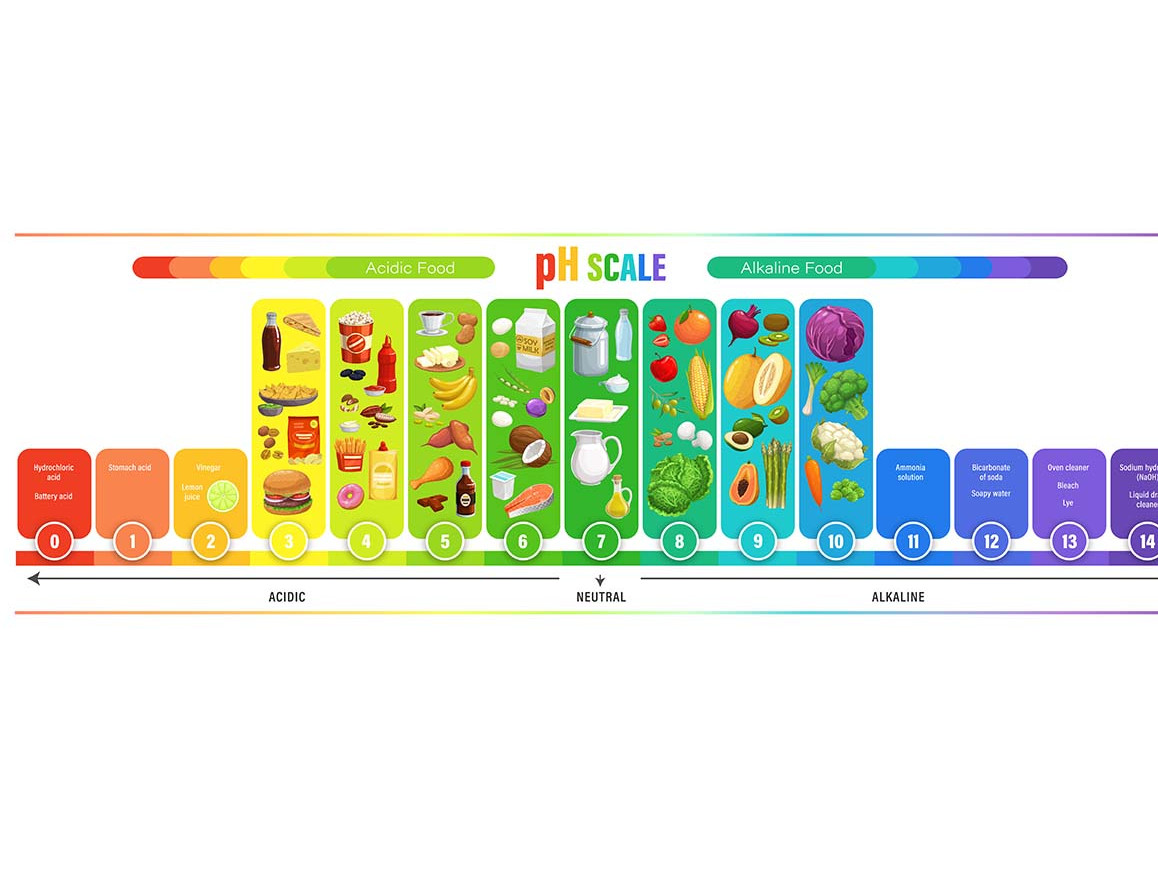

pH is a measure of the acidity of an aqueous solution. Dry substances, powders, pure fats, and oils do not contain water; therefore, their pH cannot be measured. Measuring pH provides insight into one or more properties of the (final) product, such as structure, foaming ability, shelf life, colour, and/or taste. pH can range from 0 to 14, with 1 being strongly acidic and 13 highly alkaline. A neutral solution has a pH of 7.

pH is expressed as the negative logarithm of the concentration of H3O+ ions in the solution, defined in formula form as:

It's often stated that pH measures H+ concentration. The correct reference ion is the hydronium ion (H3O+), which forms as

pH can be measured using strips, a pH indicator in the solution, or a measuring instrument.

Measurement with a strip is based on the property of the chemical compound litmus, which turns red in an acidic and blue in a basic solution. pH can also be determined by dipping a piece of litmus paper into the liquid. The colour-changed strip is then compared with the provided colour scale.

In (chemical) processes, it is often necessary to know the pH in the liquid or to adjust it to a different value. This can be done by adding a pH indicator liquid that changes colour within a narrow pH range. However, these pH indicators are not food grade.

Instruments for measuring pH all operate on the same principle: a sensor (electrode) sensitive to the hydrogen ion determines the concentration of hydronium ions and compares this with a reference signal. The measuring electrode gives a potential based on the present hydrogen ions, while the reference electrode gives a constant potential. The potential difference between these two is a measure of the pH of the solution.

It's important to know that the temperature factor affects the potential difference between the electrodes. At lower temperatures, the voltage decreases, and it increases at higher temperatures. For accurate measurements you must compensate this. Modern pH sensors usually have Automatic Temperature Compensation (ATC).

There are various types of pH sensors, including sensors with a pointed tip for measuring in 'solid substances' and sensors with a knife in front of the tip for making incisions in, for example, meat.

Contamination on the sensor can significantly disturb the measurement. pH meters still display a value despite contamination, but it's crucial to understand that this value is often incorrect. Cleaning the electrode should only be done with a special cleaning solution to avoid damaging the sensitive membrane.

Calibrating the pH meter is done with buffer solutions. Often a two-point calibration is sufficient, using a buffer solution in the acidic range (pH 4) and in the neutral range (pH 7). Sometimes a three-point calibration is performed, adding a measurement in an alkaline buffer (pH 10). Calibration should be performed at least every day (prior to measurement).

pH measurement must be performed correctly. The used methodology and approach should be clearly reported. Only this way can the data be accurately interpreted and the measurement replicated by others.

REFERENCES:

HTTPS://NL.WIKIPEDIA.ORG/WIKI/LAKMOES

HTTPS://NL.WIKIPEDIA.ORG/WIKI/PH-INDICATOR

PH THEORY GUIDE METTLER TOLEDO

HANNA INSTRUMENTS, WHAT IS PH

Source: Vakblad Voedingsindustrie april 2024