Van der Plas Sprouts is a market leader in the field of sprouts. The company is growing: there is increasing interest in a healthy (vegan) diet, to which sprouts are an excellent addition. Due to the short processing times, a properly functioning production process is indispensable. Flexibility is also important because of the ever-changing demand from the market.

'We've never had a breakdown'

Van der Plas Sprouts is a family business. The third generation is now in charge. "My grandfather started the company," says Eva van der Plas. "He was a mushroom grower, but switched to bean sprouts because of the competition. My father managed to expand the company. We now grow and sell around twenty types of sprouts, eight of which are organic. My brothers and I have taken over our father's business." The tasks are well divided between the siblings: eldest brother Pepijn is in charge of purchasing, Eva is general manager and Sven, the youngest, is a cultivation specialist.

Sprouts are young, newly sprouted plants. They are harvested from seeds of vegetables such as broccoli, radishes, beets and leeks. "We do not allow the vegetables to mature, but harvest them just after they have sprouted. This ensures that they contain a high concentration of nutrients. An entire stalk of broccoli grows from a single seed, for example. In the fully-grown broccoli, all the vitamins and minerals are distributed; in the seedling, these nutrients are concentrated. In terms of vitamins and minerals, 10 grams of broccoli sprouts is equivalent to 300 grams of cooked broccoli."

Jasper Slaghekke (account manager Sismatec), Tessa IJntema (sales support Van der Plas Sprouts) and Eva van der Plas (general manager).

Cultivation and packaging takes place at a single location in Broek op Langedijk. "Part of our company is set up as a cultivation area. Elsewhere in the company, the vegetables are packaged," Eva explains. "The cultivation process is short, the circumstances differ for each type of sprout. The growing process varies from four to fourteen days. Once packaged, the sprouts have a fairly short best before date. So we have an enormous turnover rate. Our company never stops production: we also work on Sundays."

Van der Plas Sprouts considers food safety to be of paramount importance. "We comply with all applicable standards in the field of food safety and hygiene. Our seeds are tested for the presence of various micro-organisms." In addition, the company does extra tests to ensure food safety. The culture water, for instance, is randomly tested to exclude the presence of any micro-organisms. By doing so, the company wants to bring the healthiest possible product on the market. "We are the leader in the industry in this regard, as we test throughout the entire growing process."

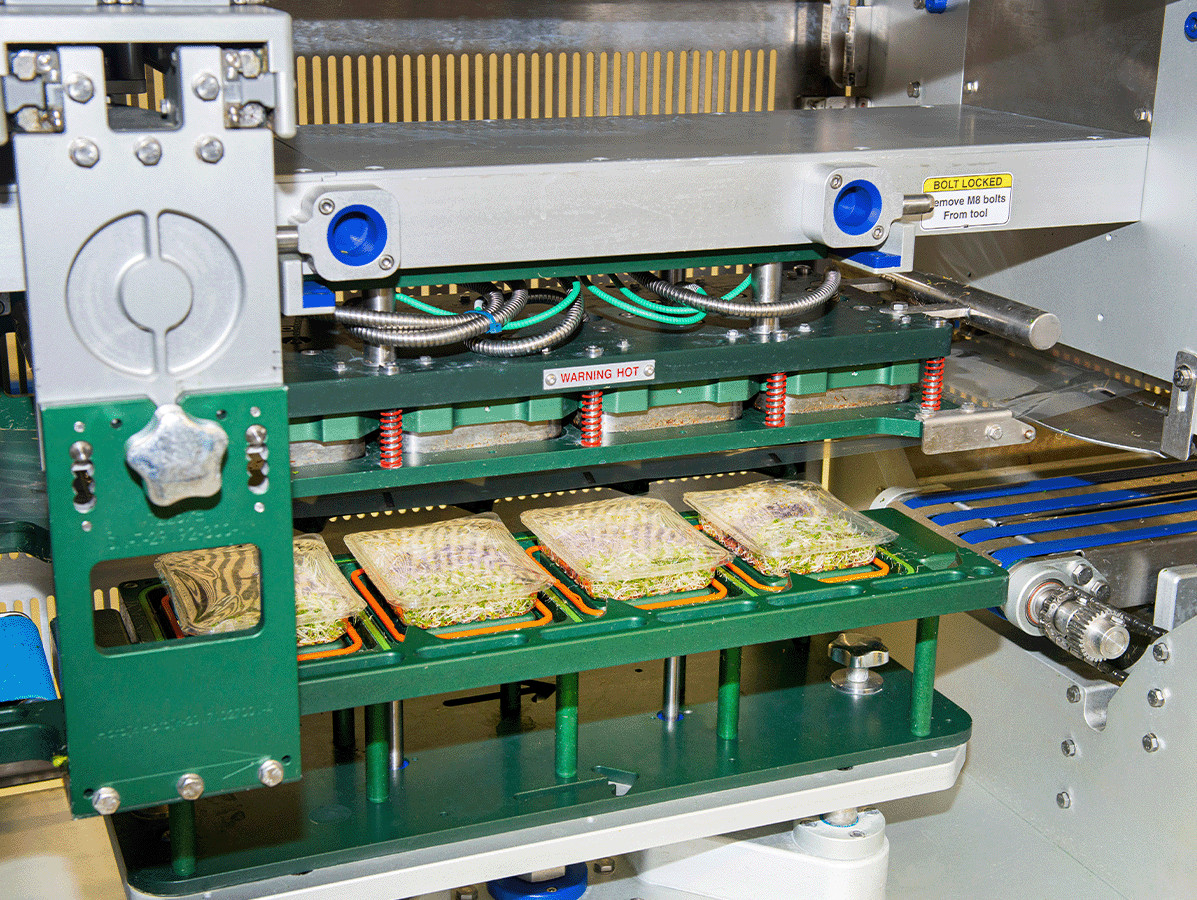

Because of the fast turnaround time, the family must be able to rely on the machinery. "We can't afford to have machines shut down." They therefore work with established partners, such as Sismatec. "In 2018, we purchased our first Proseal machine from the company. It is a robust packaging machine, which is easy to operate. A big advantage is that all the electrics are on the top of the machine instead of at the bottom. This means that it is easier to clean. When you hose down the machine, you don't have to worry about water getting into the electrics. Sprouts are small, stick to the belt and easily get caught in something during the packaging process. That requires a thorough cleaning method."

Van der Plas Sprouts now has four Proseal packaging machines. "We have not experienced any major breakdowns and are very satisfied with the machines and the cooperation with Sismatec. They offer good service and can deliver quickly." Customers regularly ask for new packaging, for example because of a new arrangement of shelves. "A new mould has to be ordered for this. While delivery times with other companies can be several months, Sismatec and Proseal manage to deliver new moulds within four weeks. And faster if necessary. This means that we can respond flexibly to customer wishes. Very important in our sector."

Van der Plas Sprouts supplies retail and food service in the Netherlands and abroad. The company is growing beyond its capacity. "We will continue to expand in the coming years. We have noticed that there is increasing demand for our products. They fit perfectly into a healthy diet and give dishes more flavour. Moreover, we work in the most beautiful company in the Netherlands, with a very close team. We are really making it happen together."

www.vanderplassprouts.nl

www.sismatec.nl

Photos ©Wick Natzijl

Source: Vakblad Voedingsindustrie 2022