How do you guarantee quality, continuity and service in times of scarcity of raw materials and personnel? How do you incorporate sustainability into this process? And how do you achieve growth? Van der Zee opted for centralisation, construction innovation and working smarter.

Each project is unique. Also at Van der Zee it is custom-made'.

Traditional butcher's shop since 1925, Van der Zee has worked from four production locations. Due to sustainability, scarcity in craftsmanship and a desire for growth, the company opted for centralisation at two locations: a head office with production location in Emmen and a catering distribution centre with production location in Twello. These locations will be renovated in terms of construction and sustainability, with the focus on the future.

"We want to supply all customers from one location, Twello. Here we will store a larger stock of meat. Meat is scarce and we want to make sure we can deliver good quality. That means bringing in more ourselves, and we need space for this," explains managing director Arend Jan Pothof. As the son and grandson of a butcher and having worked for Van der Zee for 13 years, he knows better than anyone how important good quality meat is. The company supplies meat to Hanos butchers in the Netherlands and Belgium and values craftsmanship, customisation and service. This centralisation will result in fewer transport movements and therefore less CO2 emissions, amongst other things.

Arend Jan continues: "In Emmen we have our sausage-making facility. We will merge this with the kitchen for our second branch, Distrivers, which supplies food and drink to hospitals and care institutions. This is more efficient and more sustainable, because the merger means we can use the kitchen 24 hours a day: at night for the sausage factory, and during the day for Distrivers. This also enables us to offer more choice to cookery students (ROC Emmen) and train them to be good cooks. Thus, we contribute to a larger share of qualified newcomers on the labour market."

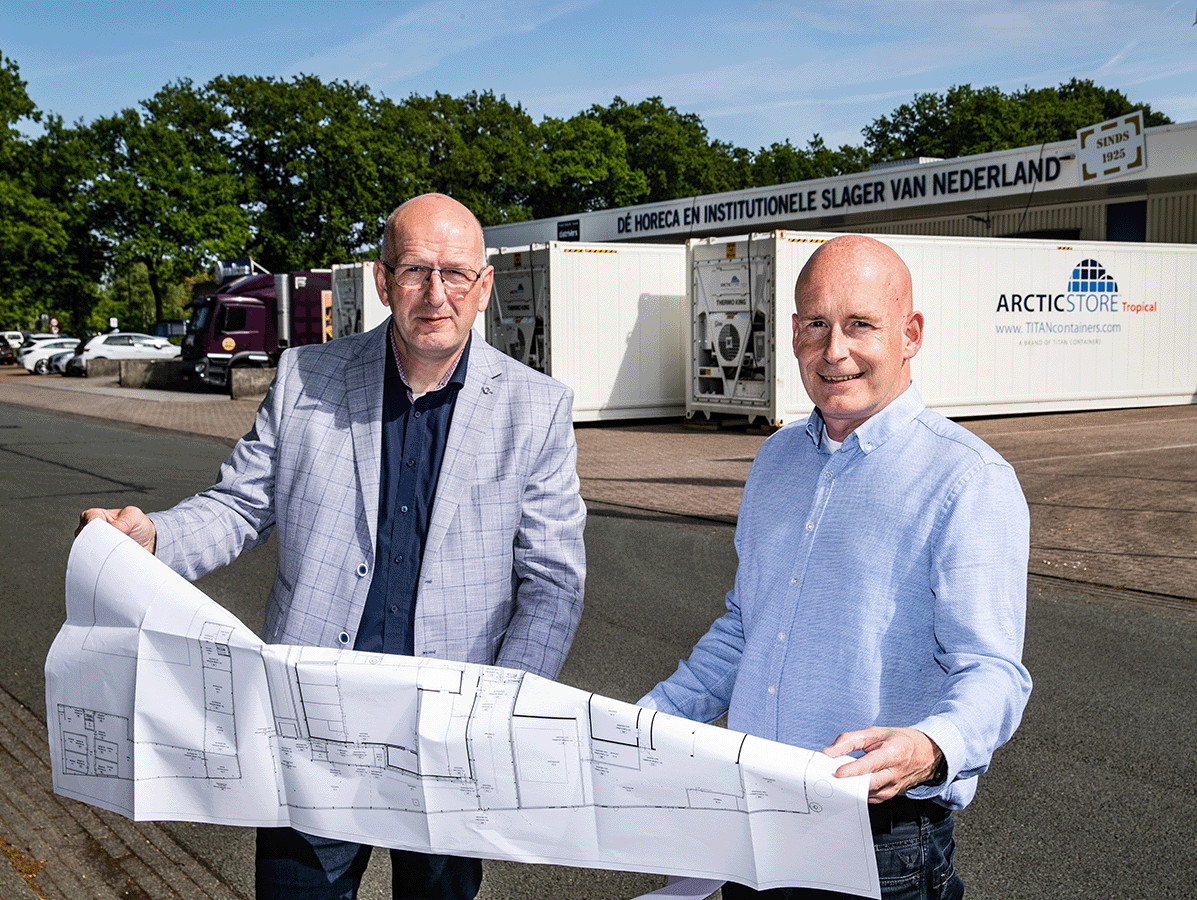

Van der Zee has great plans. However, this requires an adjustment of the current situations: a new building in Twello, and renovation and new construction in Emmen. "We are now in the final phase of the tender process. We will start with the new building in mid-2022. We also want to put the rebuilt section into operation in the spring of 2024. Albert Ensing enthusiastically takes over from Arend Jan. He has been working at Van der Zee since 2018, with over 40 years' experience in the meat processing industry. As operations director, he is concerned with the construction plans and has involved RBK in this. "Because we have worked pleasantly with them before. We know meat, they know construction. We need their expertise for our construction project. Hans van den Hoorn, architect at RBK responds: " We consider it a nice challenge at a nice company. The cooperation is very harmonious."

RBK has been carrying out consultancy and construction projects for the food industry for more than 40 years. Despite this experience, every new building request remains a challenge. "Every project is unique. Especially during a renovation, you have to deal with all the peculiarities of the existing building, whether it's about the structures, the height, the existing installations, the question of what you replace and what you don't. This is also the case for Van der Zee. At Van der Zee, too, this is custom work. Hans mentions a few more specific challenges: "We are transforming an existing, refrigerated production company into a location where cooking will soon take place. Of course, the building must meet all requirements structurally, but the change of use creates technical challenges in the building installations; for example, how do you deal with the large differences in temperature and the risk of condensation, how can you increase energy efficiency and reuse to reduce energy costs?

The fact that refurbishment takes place while production continues is an additional concern; how do you do this without risk to employees, or food safety?" "Our shipments have to keep going at all times," adds Albert. "A day without food and drink is unthinkable in healthcare!"

Hans van den Hoorn and Albert Ensing

There is a lot of mutual trust. Albert: "Sometimes things don't go according to plan at work, then it's about how you solve the problem together. And in this building project, we again wanted a construction partner who is professional and independent. It is also very important to us that the building and the installations are considered as a whole, that this is defined in unambiguous specifications and that we receive comparable offers from suppliers. RBK is more than capable of doing that. Hans: "I'm very curious about the final result." Albert: "I'm looking forward to when it's finished and we can realise even more growth."

Beeld: © Foto Hissink

Source: Vakblad Voedingsindustrie 2022