Foaming occurs when processing fresh vegetables and legumes. When Coroos in Kapelle started processing organic products, the company developed an organic foam inhibitor in collaboration with Van Meeuwen Additives. It was a complex process, but it ultimately yielded an organic antifoaming agent that performs well under all conditions.

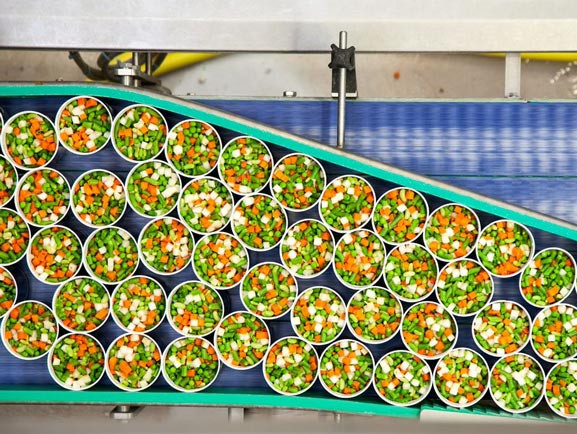

Coroos ranks among the top three European producers of fresh vegetables and legumes in jars and cans. Each week, the Kapelle facility fills one million jars and cans, increasing to 1.1 to 1.3 million during the harvest season. In the production process, the raw materials are pumped through the factory, where whipped proteins form foam. This foam can disrupt the production process, create dangerously slippery floors, and is not hygienic. The solution is to add foam inhibitors. These were initially silicone-based, but since Coroos switched to organic products in 2018, they use an organic antifoam, developed in collaboration with Van Meeuwen Additives.

Jacco Bras, Sanitation Manager at Coroos, and Roderick Van de Weg from Van Meeuwen Additives began developing an organic/biological foam inhibitor in 2018. Jacco shares, "I presented my issue to Roderick. He came back with several proposals. We hit the floor and tried out a number of products. It was a matter of trial and error to find the ultimate solution. We believe we've come a long way over the past few years to a very effective antifoam."

"It's a complex process for a wide range of products. Sometimes we thought we’d found it," Roderick continues, "but then we were faced with other production parameters such as higher temperatures or more protein release due to slightly different raw material specifications. Weather conditions also affect it. You're working in a dynamic environment. It requires constant adjustment to find an antifoam agent that fits."

© Coroos

Because of varying parameters, Coroos traditionally used two different foam inhibitors in its regular production. With the switch to organic products, a conscious decision was made to use a single organic antifoaming agent. "It performs well to very well with all our products, both organic and non-organic. This has made the production process much more efficient," says Jacco. "Our antifoaming system consists of thin hoses running throughout the factory," he explains. "Sometimes it took half a day to empty and flush these. You can't risk the piping not being clean. If you can't demonstrate during an unannounced audit that you're working with an organic product, the consequences are severe. The organic end product would not be approved. Using only one organic antifoam eliminates this risk. It also makes assessment management easier."

The increasing focus on food safety and stricter regulations lead to higher costs for food producers. The organic antifoaming agent used by Coroos is nearly three times more expensive than a conventional agent. Roderick acknowledges that organic agents are more costly but points out that it's a smaller market. "It's less common. We set up a special project in 2018 when we saw the organic trend emerging. Our organic antifoam complies with strict Skal regulations, and we've been audited on that."

© Coroos

With current disruptions in the logistics supply chain, Roderick notes that securing raw materials on time and at the best price is a significant challenge. Substituting with cheaper or different products isn't an option. "You get a different product. We never do that without consulting with customers. When we saw improvements in the coronavirus situation early in 2021, we decided to stock up as much as possible. This allowed us to always supply our regular customers. We aim for long-term relationships." Jacco agrees: "We’re moving away from the spreadsheets and towards relationships. You don't switch suppliers every year just because someone else is cheaper. Give each other margin and maintain continuity. During a period of extreme price increases, Van Meeuwen called me: if I wanted to order quickly at the old price. That's what you want in a relationship."

Retailers are setting higher standards for food safety and increasingly emphasizing corporate social responsibility, demanding the same from their suppliers. Jacco considers this, for instance, in his choice of suppliers. "It's not yet in our DNA, but we're working on it. Whenever possible, we choose the party with the most focus on CSR. In our new building, needed to centralise storage, we are already planning for the installation of twenty thousand square meters of solar panels on the roof. Our production water, after treatment, no longer goes into the Westerschelde but to local farmers for irrigation." Van Meeuwen also values sustainability. "We are EcoVadis certified and strive to improve our rating every year."

To smooth out production peaks from mid-June to mid-October, Coroos is focusing more on legumes that are already cleaned and dried and ready for production. "The peak isn't so much in volume but in the production process. Fresh vegetables require more processing than legumes," Jacco explains. "We're also working on product innovations like fruit mixes that have a shelf life of three or four weeks in the refrigerated section and new vegetable mixes and different packaging that serves other markets. We are now working on vegan tuna (currently in testing). We're also trying to boost winter production, which reduces fluctuations in staffing levels. It's a very dynamic market," he concludes enthusiastically. "I've been working here for forty years, and every year is different!"

Source: Vakblad Voedingsindustrie 2024