The reliability of ample clean and safe drinking water is increasingly under pressure. Water usage in the food industry requires even more stringent measures. Disinfection using UV-C light is a dependable, cost-effective, and sustainable method to ensure water safety.

While the quality of drinking water in the Netherlands is currently satisfactory, its availability is becoming a concern due to increasing drought and pollution. This situation necessitates the reuse of water and the use of alternative water sources, which is crucial for the food industry. Water from various sources may contain different levels of microorganisms, even after standard treatment, posing safety risks, especially as microorganisms can proliferate in stagnant water, like in a storage tank or buffer.

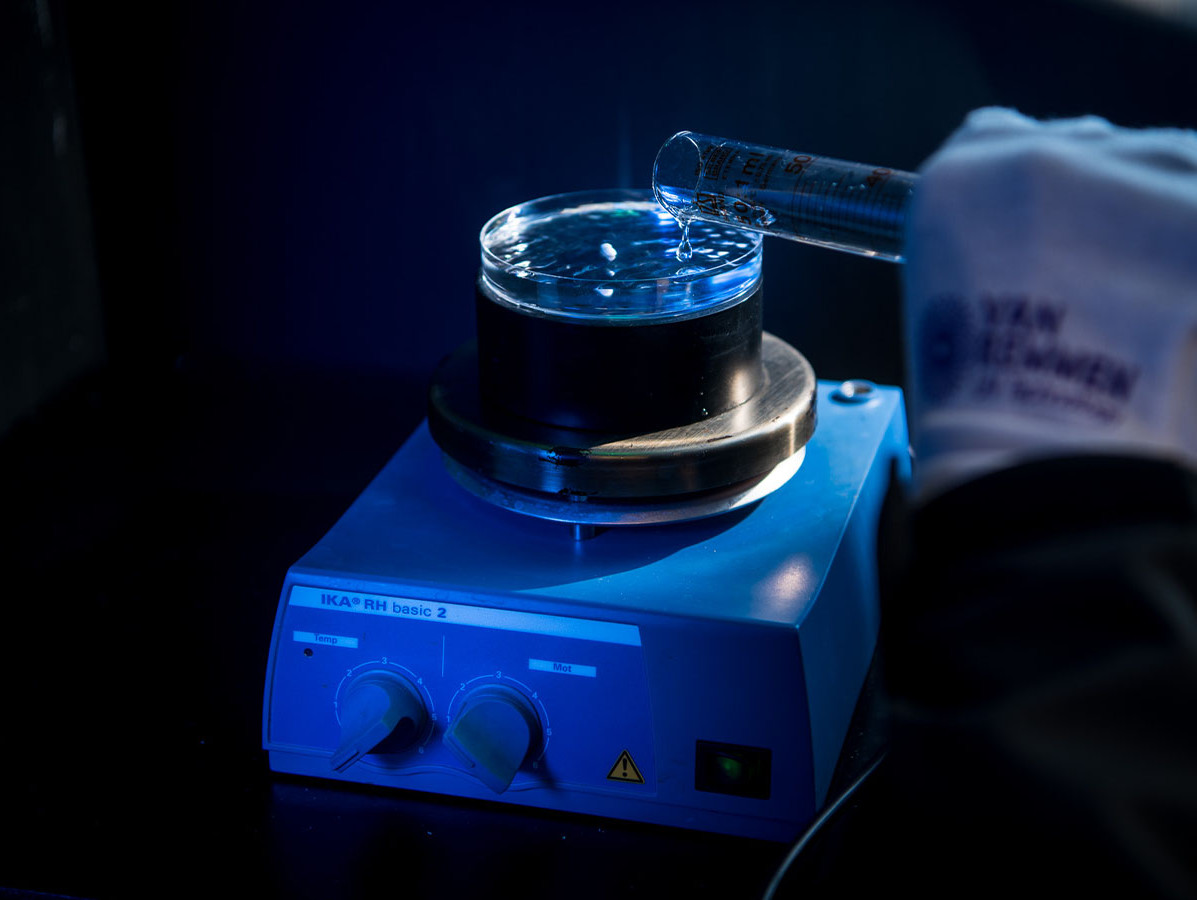

To guarantee the safety and quality of products, it is vital that process water is of the highest quality, regardless of its source. To ensure this, an increasing number of food companies are turning to UV disinfection. This treatment destroys the DNA of bacteria, viruses, and other pathogens, preventing their multiplication and rendering them harmless. UV radiation is produced by a UVC lamp, has short wavelengths, and is outside the visible light spectrum. Organisms absorb this radiation, which damages their DNA. UVC is proven effective; it adds nothing to the water and does not alter its taste or smell.

UV reactors are installed at critical points in the piping system, such as at the point of entry for incoming water, in storage tanks or buffers, or just before water is used in the production process (point of use). The UV reactors eradicate all microorganisms present in the water. Special attention is given to buffer tanks. In a cold storage, they contain cold water, which usually poses few problems. However, a tank in a technical room can rapidly develop biofilm growth during warm summer temperatures. This issue can be prevented with a UV flow-through system over the tank or with lamps inside the tank. Even the headspace above the water level can be kept hygienic with UVC light.

Installing a UVC system in the water pipes is a job for a plumber. It is advisable to install a bypass so that water usage can continue uninterrupted during major maintenance. With 'three-way valves' before and after the UVC reactor, the bypass can be easily used. The bypass pipe should be sloped and equipped with a drain valve at its lowest point to prevent water stagnation, where bacteria could grow. For companies with a standard water connection of 3.6 m³/hour, validated systems start at €2,566; for larger companies with a connection of about 7 m³/hour, the starting price is €4,259.

At a company producing vegetarian products, where a lot of water is used in the production process and for cleaning, microbiological tests have frequently detected bacteria in the water. The consequences are significant: pipes and buffer tanks must be chemically or thermally cleaned, and microbiological tests must be redone. The costs are substantial, often higher than the preventive investment in a disinfection system. However, note that a UVC system is not an alternative to a Legionella management plan! It does, however, significantly reduce the likelihood of encountering this bacterium.

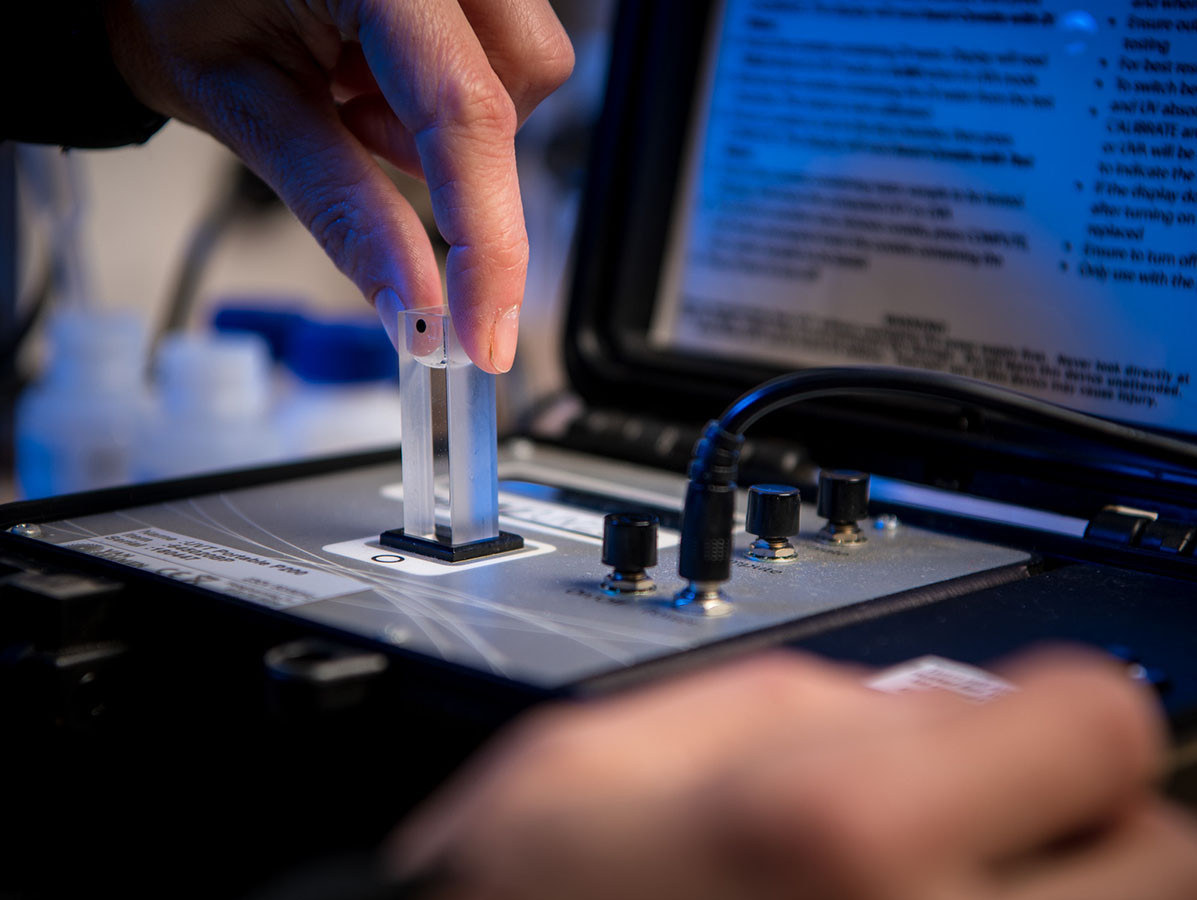

UV systems come in various types and price ranges. When safety must be 100% guaranteed, it is important to opt for a validated UV system. If you are installing a UV system at the point of entry, it is crucial to choose one with a Kiwa certification. This certification ensures that the system maintains the highest hygiene standards and does not use chemicals or materials that could pose risks to the drinking water supply. The systems from Van Remmen UV Technology are validated and carry a Kiwa certification, meeting the highest standards. They are proven and demonstrably effective under all conditions. By using low-pressure UV lamps and an innovative flow management system, each drop of water receives the exact dose of UV light needed. This ensures no microorganisms escape and no energy is unnecessarily used, bringing together safety and efficiency.

Photos ©Van Remmen

Source: Vakblad Voedingsindustrie 2024