In 2019, a Listeria Monocytogenes infection at a meat producer in Aalsmeer caused six deaths, two miscarriages and 35 cases of illness. The source of these infections could be traced thanks to Whole Genome Sequencing (WGS). What can this promising technique mean for the food industry?

‘With the new techniques of DNA sequencing, you can determine whether the positive samples found are strongly related to each other'

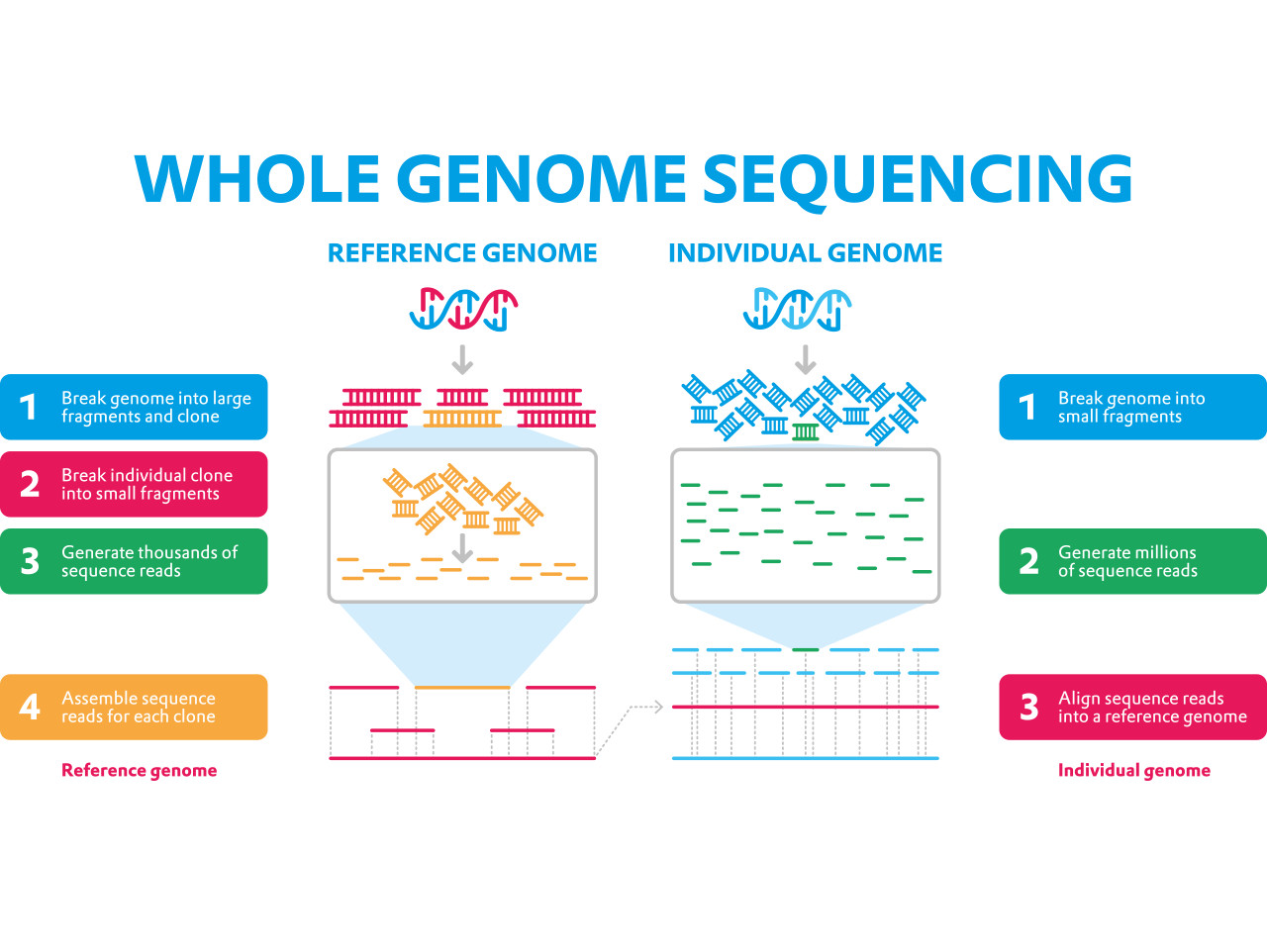

With the new techniques of DNA sequencing, a food processing company can detect sources of Listeria infections at an early stage, so that adequate measures can be taken quickly. In order to prepare the industry for the possibilities of this technique, the two-year Precision Food Safety project started in September 2020. The LCAB (Leiden Centre for Applied Bioscience) of Leiden University, food companies, research institutes and companies involved in hygiene solutions for the food industry participate in this project. Within this consortium, Eco2Clean has the role of adviser/initiator in the field of hygiene and cleaning. The research makes use of the MinION; a handy and relatively cheap DNA sequencer.

"There is a constant pressure of contamination by Listeria; from the raw materials and other sources in the production environment," says Gert Visscher, director/owner of Eco2Clean. "Sometimes the source lies in the supply of raw materials. With a clear picture of the DNA of the raw material contaminated with Listeria, the suppliers can be identified. By sequencing the contaminated batches, it is investigated whether the Listeria bacteria found are closely related. If that is the case, it is highly likely that the supplier in question has a persistent source of contamination. Measures can then be taken quickly to exclude the supplier, or to ensure better hygiene in his company, so that the buyer of his raw materials also runs less risk. If the DNA is virtually unrelated, there is a constantly changing source of contamination. Taking measures in the chain is then much more difficult. A food company will have to organise the hygiene in its own company in such a way that a possible contamination is controlled, or better yet prevented.

The source of contamination may also be within the company itself. It is known that in many food companies a positive environmental sample is found regularly, especially in companies that work with raw materials that are naturally contaminated with Listeria, such as raw vegetables, unpasteurised milk, raw and cooked poultry, fermented meat products and raw and smoked fish. "In itself, this need not be a shocking finding, provided it is clear where the contamination comes from," Gert says. "It is then important that sufficient measures are taken to control the contamination and to keep the contamination level low. DNA sequencing can be used to determine whether the positive samples found are strongly related to each other, or have a repeatedly varying DNA profile. If a strongly related DNA pattern is found on positive samples for several days/weeks in a row, there is a source of contamination within the company itself. Time to sound the alarm as a quality manager!"

By performing very intensive environmental sampling, the possible source can be traced. This requires a great deal of knowledge of how to clean effectively and deeply, but sometimes simply a fresh pair of eyes. "Infections that are present in the same company for a long time are almost always due to inadequate cleaning, usually not consciously. It may be a case of operational blindness, which means that one simply overlooks the source of the problems in one's own company," Gert continues. "The experts from our Consultancy business unit are regularly asked for advice and support. They check working methods, constructions, cleaning agents, application times, temperatures and pressures. Where possible, we optimise these factors. The search for the source of contamination is very intensive, but with the right techniques and the use of DNA sequencing, the source can be traced much more quickly and accurately. That can prevent a recall or worse.

Metagenomics for overall microflora

For the food industry, the Precision Food Safety project team is working on making new technology available by means of Whole Genome Sequencing (WGS) of Listeria Monocytogenes, among others. In addition, the project team is investigating the application of analysis techniques such as Metagenomics. This analysis is particularly interesting for mapping out the general microflora. It is possible to look specifically at the influence of cleaning, air distribution, staff movements and material movements on the spread of this flora. With this information, a company can take much more specific measures to reduce the overall microbiological pressure within a production location. In November, Eco2Clean will start testing this new, innovative technique at one of its clients in the fish processing industry.

https://www.hsleiden.nl/bio-informatica/onderzoek/precision-food-safety

Source: Vakblad Voedingsindustrie 2021