Is that organic tomato really organic? Do these strawberries, raspberries or berries carry the hepatitis-A virus or norovirus, or is a full pesticide screening with retail specification required? Questions that TLR, newcomer to Dutch Fresh Port, wants to answer: based on thorough analyses with state-of-the-art techniques.

"Food must be marketed reliably and safely at all times. That is what we stand for," says Harm Janssens, director of TLR. "We are the ambassador of truth". Recently TLR - part of the family business Peterson of which Control Union Certifications and Inspections are also part - moved to the Handelsweg 60-70 in Ridderkerk. Before the major renovation, this building was a cold store for Van Gelder fruit and vegetables. Now the operational laboratory departments are located on the ground floor; the heart of the company. Here, analysts carry out countless tests and analyses on foodstuffs, animal feed and biofuels using the latest techniques. The offices and technical areas are on the first floor.

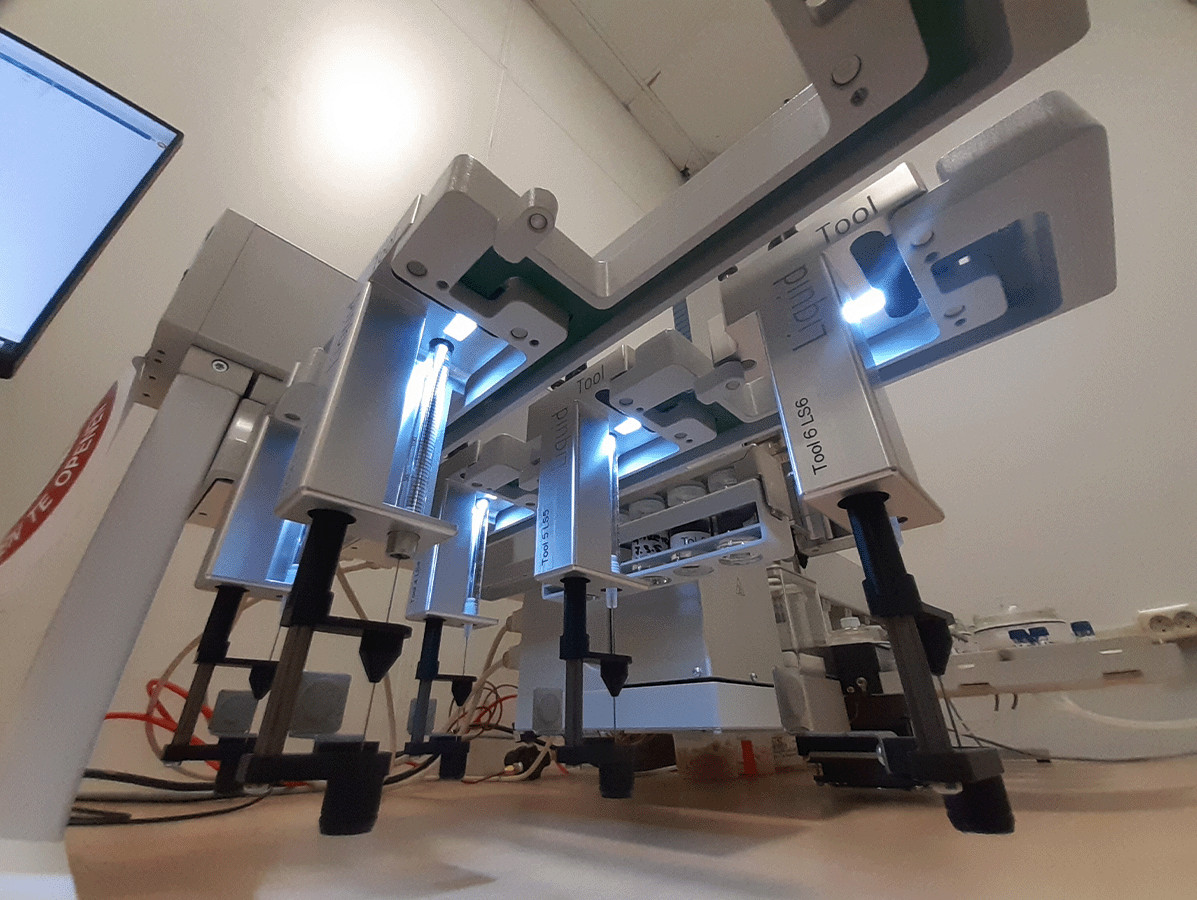

TLR is constantly innovating. "Our director is really our creative brain," says Arno van der Heijden, account manager at TLR. "Harm always has new ideas and sees possibilities everywhere. For example, there is a super-fast robot for fully automated virus determination, conveyor belts have been installed that transport the incoming samples to the sample preparation area, and the sample jars travel further through the building by airmail. Of course, this system was first thoroughly tested with empty jars; it turned out to work very well. Even with glass jars". A major advantage of this system is that it reduces the number of walking movements and speeds up the process. In addition, the lines of communication at TLR are figuratively short, which means they can scale up quickly. The latter came in handy during the corona period: "We temporarily had to analyse 3,000 nasal and throat swabs a day for the coronavirus. It was essential to work very clinically. This had an additional positive effect: the biosafety level was raised from 2 to 3, so that we can now analyse other viruses in addition to norovirus, hepatitis and corona."

As a newcomer to Dutch Fresh Port, TLR has focused strongly on sustainability with its building. On the roof there are large heat pumps that produce cold water of 5 degrees and hot water of 55 degrees. This water circulates throughout the building and heats each space separately. There is no gas connection. They work with large heat exchangers that recover heat from the analysis equipment. In addition, there are huge savings on drinking water with an internal cooling water network on a heat pump and there are plans for solar panels. Harm: "We are not yet completely energy-neutral, but we hope to be.

Back to what it is all about at Handelsweg 70: analysis. Name any food scandal and TLR has analysed it. Harm: "We found that steak sold as beef was in fact horse meat. And when three people died in the Hamburg region after eating salad, the whole sector was in turmoil. Dutch cucumbers were wrongly suspected; no one bought them any more. Partly with the help of TLR's analyses, the real cause came to light: it was sprouts infected with river water.

TLR's slogan is 'the guarantee to your promise'. "What does that mean? It stands for our cooperation in guaranteeing the agreements our customers make with their customers: through service, and through quick analyses 'on the spot' that one can follow online."

"We also test before something becomes an issue," continues the director. "We do that when the market asks for it, of course, but also based on information we receive from the government and the European Food Safety Authority. And if new laws and standards are in the making, we include our customers in the conditions and requirements early on," he assures. "Because if you wait as a company until a new law is ratified, you are too late and you often fail. Examples? The cumulative effects of various toxins are increasingly being taken into account. It is also quite conceivable that certification authorities will ask for authenticity research in the future: such as 'does this soy really come from the region stated on the label'? We can establish the latter by means of an IRMS analysis; for example, by analysing isotopes and rare earths. In this way, we can contribute to more transparency in the food and feed chain."

Source: Vakblad Voedingsindustrie 2022