GEA supports startups, ingredient suppliers, and food processors in developing, scaling, and producing the nutritious new foods consumers are looking for. How do they do that?

With years of expertise, specialised 'New Food Teams' and test centres around the world, GEA has become a partner of choice for sustainable food technologies. ‘New foodstuffs’ aka 'New Food', can be interpreted broadly. "It is a fascinating world," says Christelle Theis, Senior Director New Food. "With our team, we basically focus on all protein-rich alternatives to animal meat."

"What continues to grow are plant-based ingredients and products. We have been supplying a complete portfolio of processes and technologies to our customers for years in that area. Most of the vegetarian products and meat substitutes that are on the market today are produced wholly or partly with our technology. Nevertheless, there is still much to learn, innovate and develop in this segment. Especially in the area of protein extraction. And the taste and texture of end products will certainly be the subject of another wave of innovation. Major technological innovations such as precision fermentation, and cell and gene therapy are in full development. Food produced with ingredients based on fungi and algae, and cell culture are also emerging. It's great to help develop new food technologies, to contribute to making the food chain more sustainable."

With all the uncertainties surrounding the new ingredients and possibilities, GEA strongly believes in the 'test before you invest' principle. In specially equipped Technology Centers, customers can therefore extensively test their processes, machines, ingredients, and recipes; for example, to take them from laboratory scale to industrial production. Decades of GEA expertise, supported by experienced food technologists and engineers, accompany them in this process. "The Technology Center is in fact a large playground," says Marcel van den Heuvel enthusiastically. "You are free to experiment here because you are not restricted by production pressure. You can make mistakes, try things out. We tell the customer what we do and why we do it. We can show what results you can achieve by pushing certain buttons. In turn, we also learn a lot from our customers. We really work together."

'Engineering for a better world'

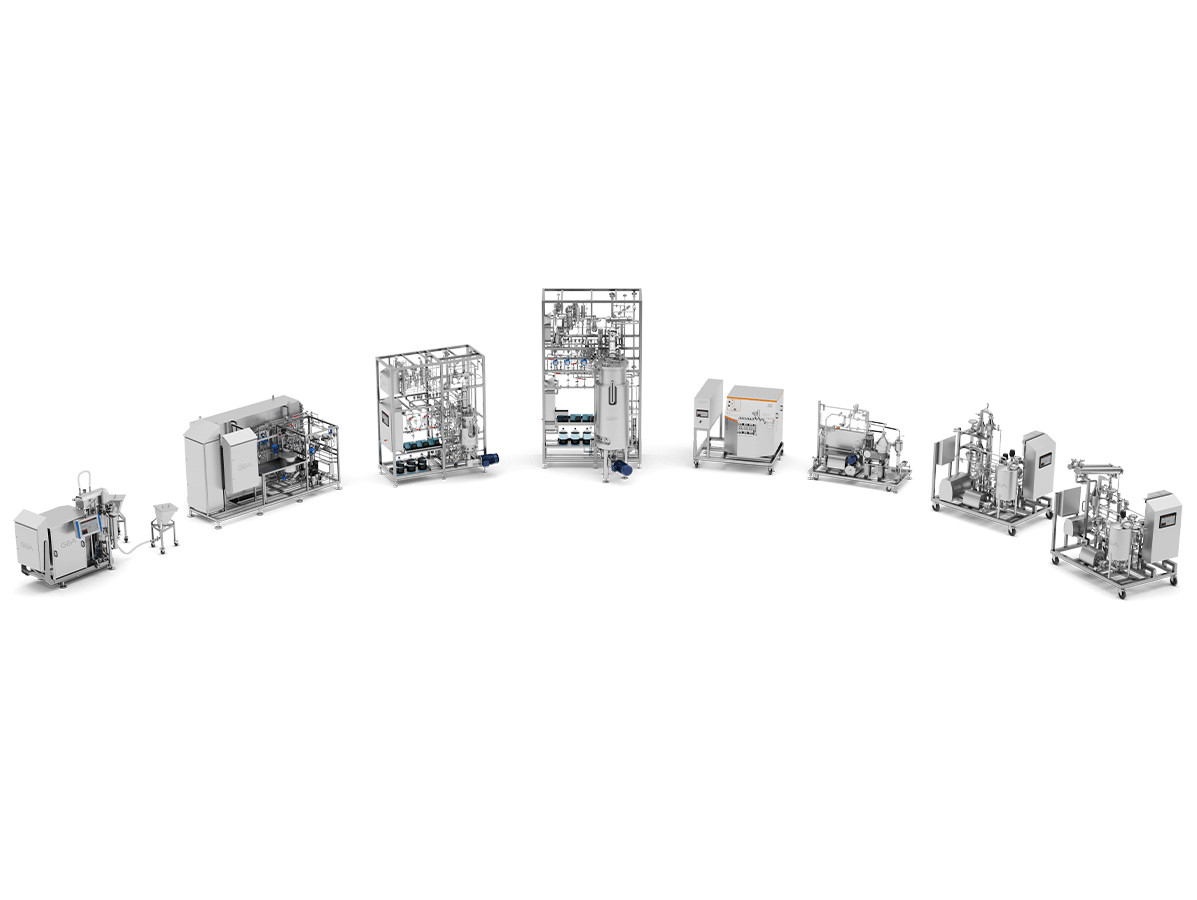

"The big advantage for our customer," adds Stefan van Hoof, Director GEA Food Technologies Benelux, "is that without heavy investments in a pilot plant, they can generate a proof-of-concept for their process within a very short time, for example to support a business model for scaling up to commercial production. Recently, we have also acquired complete, mobile and modular industrial test units. These are specifically designed for cultivation and fermentation processes for food applications. The units include 2-in-1 fermenter/bioreactor equipment, high-shear mixing and UHT units, and homogenisation, separation and membrane filtration units."

Erik Tempelman is a process technologist at Vivera, one of Europe's largest producers of vegan and vegetarian products and market leader in the Netherlands. According to him, the strategic cooperation with GEA as a technology partner is one of the success factors of the company's spectacular growth in the 'New Food' sector. Many food processing machines have now been supplied in the areas of mixing, coating, slicing, cooking and frying. Vivera's strategy is to move towards integrated production lines based on GEA technology. Crucial to this is the Cookstar GEN 3 oven, which offers greater flexibility than traditional linear ovens. With a portfolio of hundreds of products Vivera now realises higher production and less waste. Erik is very proud of the products Vivera makes. "We deliver great products and our customers are satisfied," he says. "My job is to make sure we do that as efficiently as possible, with as little waste as possible. GEA helps us do that every day. Our relationship is getting stronger and stronger."

Stefan van Hoof: "With our innovative knowledge of process engineering, and ground-breaking technologies for the food industry, combined with sustainable hot and cold technology, we achieve great results with our customers. How? By using an integrated approach to optimise production processes and at the same time significantly reduce CO2 emissions, energy consumption, waste and water consumption. The earlier our engineers are involved in the process, the more profitable it is," he concludes. "That's what we call: engineering for a better world!

On the photo: Marcel van den Heuvel of GEA (left) with Erik Tempelman of Vivera

Source: Vakblad Voedingsindustrie 2022