Those who want to remain frontrunners have to be innovative. That’s the principle of Heemskerk fresh & easy. Efficient, hygienic processing combined with new, smart packaging techniques guarantee the freshness and quality of dressed vegetables, salads and cut fruit.

Heemskerk fresh & easy cuts, washes, dries and packages fruits and vegetables: swiftly and at an environmental temperature of 4°C to guarantee hygiene and freshness. This pioneering company combines the old trade with innovative products, concepts and processes. And they’ve been doing this since 1960, from father to son. A real family business, which they’re deservedly proud of.

Fast, reliable and hygienic

The focus of Heemskerk lies in four product groups; dressed vegetables, salads and raw vegetables, salad meals and cut fruit. Every product group knows a large number of compositions and delicious combinations. “To supply our clients within 24 hours, a well-oiled organisation and perfect production means are essential”, Cor Heemskerk says, director and owner and the second generation of W.Heemskerk. “Mistakes lead to rejection and therefore to loss. We want to prevent that. We therefore nearly completely automated the process and use high-tech machines. Experts keep a close eye on things and intervene if necessary. During production, we use the JD Edwards EnterpriseOne software package, which streamlines the translation of received assignments to the purchase and production departments.”

The work planner choses a work order that has been created with the software system. The operator can see the size and composition of the production on a tracking screen and ensures there’s a proper supply on the conveyor belts. The conveyor belts bring the product to the weighers. Dosing takes place per component, in two speeds and with an auto-regulating correction. For composing the mixtures, Heemskerk chose for individual static weighing of each component: five in total per recipe. Cor: “This method has proven to be accurate. Should a component be missing, the process immediately stagnates. This way, incomplete mixtures are prevented. Every weigher unloads their component onto a collective conveyor belt with an adjusted time delay, which then transports complete piles of the mixture. To have production run successfully, it’s necessary that the many weighing cycles, especially the unloading of every weigher, are aligned with each other. The system is self-learning. When there’s too little or too much of the main component in the weigher, the system automatically adjust the other four component. This guarantees mixtures with the appropriate ratios. The system repeats this cycle automatically until the desired amount is produced. If there is any raw material on the conveyor belt afterwards, then the operator can decide whether to dose several more portions or to empty the belts in the opposite direction. All dosage data is transferred to the ERP system automatically, guaranteeing complete tracking and tracing.”

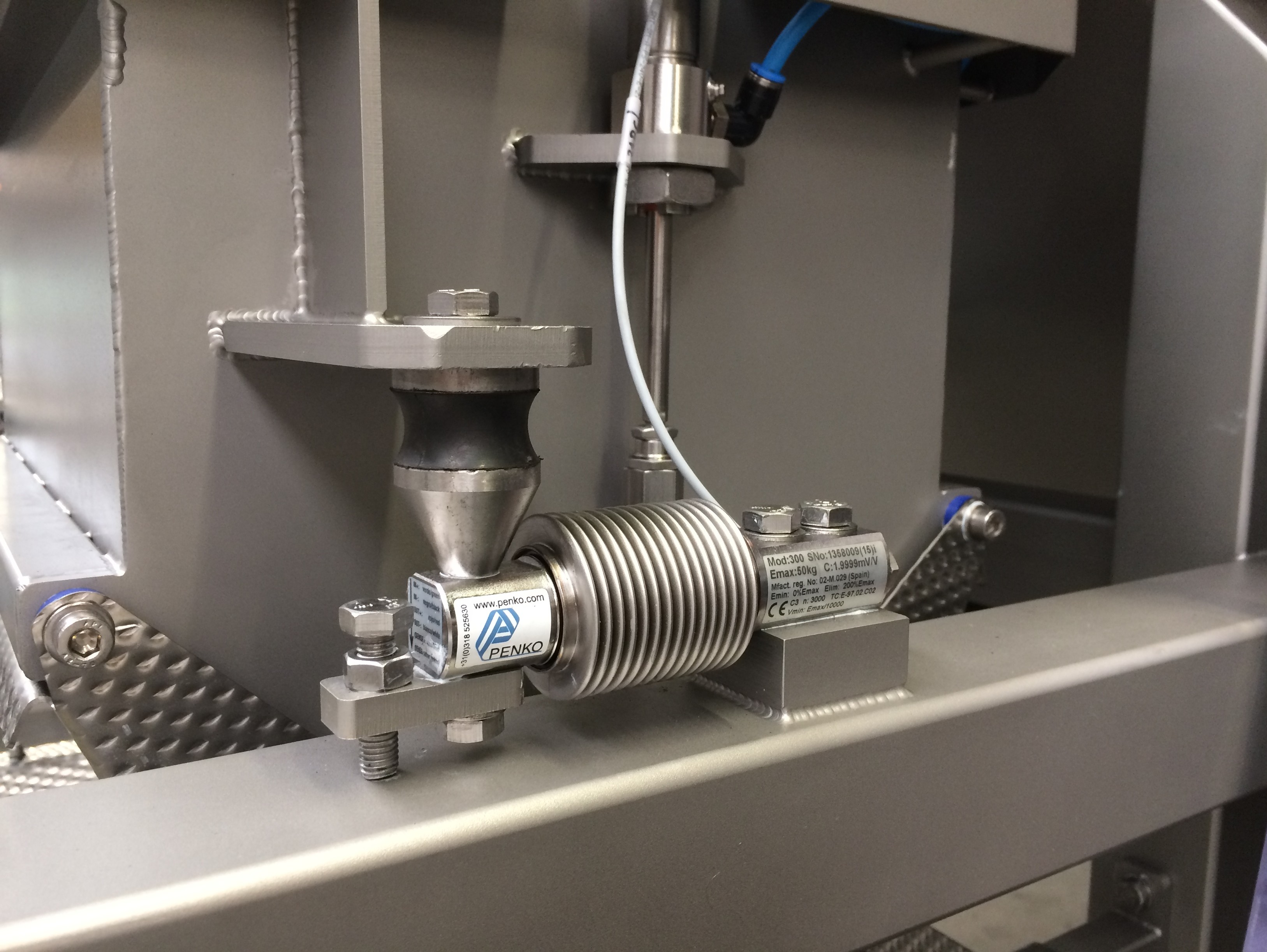

To compose mixtures swiftly, reliably and hygienically, Heemskerk uses the services of Sormac from Venlo, leading in the development and production of cutting, peeling, washing and drying lines in the vegetable processing industry worldwide. Cor: “With more than a hundred years of knowledge and experience in the branch, they’re a real specialist. For this project, they supplied us with an automatic recipe belt that consists of supply belts with weighing trays, a collecting belt and the assembly of the control components with the motor switch material; everything hygienic and carried out in a properly cleanable manner”. For the weighing sensors and control technology, Sormac collaborates with the experienced PENKO Engineering B.V from Ede. PENKO supplied stainless steel and hermetically sealed force transducers met an accuracy of 0.017%. The transducers are integrated into the production line. Although these do not come into direct contact with the product, they undergo the same cleaning process as the weighing bunkers. Additionally, PENKO installed a four-channel operating system of the FLEX type with an extra digitizer of the SGM850 type. It has five exits (0/4 – 20 mA) for controlling the supply belt. Per weigher, a separate completion sequence can be decided. The Data reporter programme retrieves the production assignment and, after the dosing has been completed, transfers the results to the ERP system. The combination of a high measuring speed with an excellent linearity and high internal solving capability, ensures optimal dosing accuracy.

Heemskerk didn’t have to change their procedures to use the new production line; everything was customised to the existing working method. This simplified the start-up and makes instructing the operating personnel simple. The switch happened without a hitch”, Cor Heemskerk says. “One year later and the system meets all demands. The self-learning features contribute to the repeated accuracy of the readied product. Order reception and production are perfectly aligned. The management can track everything in real time. And thanks to the communication with the ERP system, production manufactures exactly what’s been planned. This way, we prevent loss.”

Source: ©Penko