Fresh produce is usually frozen in packaging. Independent research shows that there is a big difference between the freezing speed of products packed in closed solid cardboard and corrugated cardboard. This has an impact on quality.

What is the freezing speed of a product packed in corrugated cardboard and what happens if you pack the same product in solid cardboard? In contrast to corrugated cardboard, solid cardboard has no insulating properties. After all, the freezing times are expected to differ. In the study, carried out by the Belgian Packaging Institute IBE-BVI, packaging filled with poultry was extensively tested. The temperature probe was always placed in the geometric centre of the box.

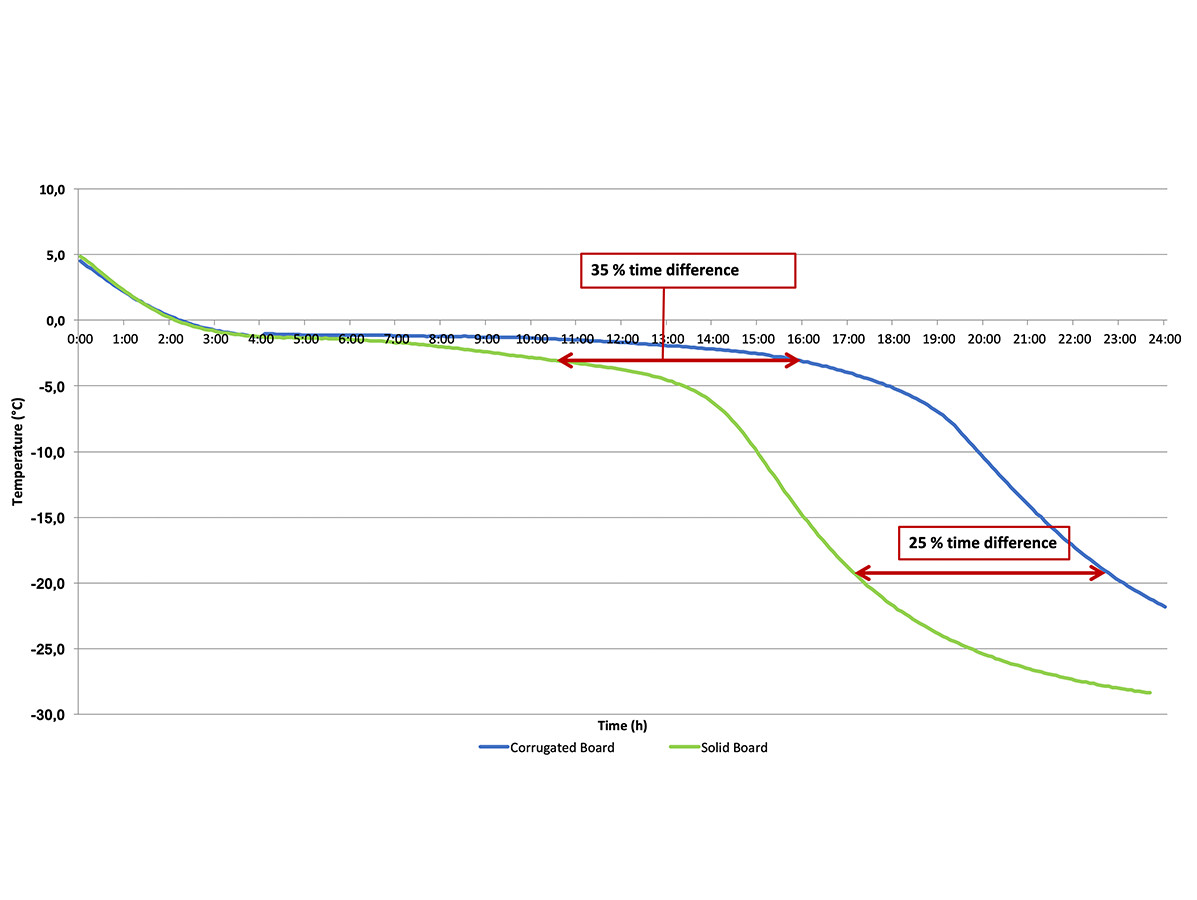

The difference in freezing speed between solid and corrugated cardboard appears to be significant. The average time needed to reach -3° C (from about 5° C) is about 35% shorter for solid cardboard than for corrugated cardboard. As a result, the natural spoilage of the packaged product in solid cardboard is more likely to stop, which improves the quality of the packaged product. At lower temperatures (to -18° C, measured from about 5° C) the difference is 25%, in favour of solid board. The use of air holes does not seem to affect the freezing speed. "It should be noted that no quick-freezing system was used, which may explain the lack of difference in the presence of air holes," explains Johan de Neef, Managing Director at Smart Packaging Solutions. "Time is often a bottleneck in processing speed", he knows. "By opting for solid cardboard packaging to freeze products, an increase in productivity of 25% can be achieved".

Source: Belgisch Verpakkingsinstituut BV

During the control study, differences were observed in the results with the same type of packaging. This can be explained by several factors: by the fact that the test material is of natural origin, by differences in full load weight and by the position of the temperature probe. Nevertheless, the difference between solid and corrugated cardboard remains undeniably large. This experiment was carried out with solitary packaging. It is likely that the observed difference in freezing times will further increase with pallet stacking.

Johan de Neef is very satisfied with the results of the survey. "The shorter freezing speed was known to us from practice, and the results of this independent study confirm our many years of experience. These results also emphasise the benefits of solid cardboard packaging for food safety and the quality of packaged products. Solid cardboard packaging is more resistant to condensation, temperature and humidity fluctuations, among other things. The high moisture resistance makes them particularly suitable for the storage and transport of fresh goods in cold stores and deep-freeze rooms. And thanks to their sturdiness, they can be stacked higher; you benefit more from the loading volume in outgoing logistics. This contributes to a cost-efficient logistics process".

The bottom-lid packaging of Smart Packaging Solutions is sturdy, compact and flexible. The 4-point packaging can be supplied with reinforced corners or double walls, depending on the requirements for transport. The 6-point variant has the bottom and lid combined and can be used as an eye-catching shelf presentation. For most humid environments, a PE coating can be applied which remains strong and leak-proof even at 95% humidity. "There are many possibilities in terms of weight, printing and finishing. There is a client-specific solution for every situation", Johan promises. "We supply durable, reliable and innovative customised packaging that guarantees quality retention and food safety. With respect for people and the environment: by wasting as little as possible, and by recycling where we can", he concludes.

Source: Smart Packaging Solutions