It has been done: making vegetable meat with the structure of a bavette, including blood, fat and muscle tissue. If you want to taste the vegan steak from the Israeli start-up Redefine Meat, you still have to go to a top restaurant. Recently, the company opened its first production location: in the Dutch town of Best. We are having a chat about it with senior vice-president Edwin Bark.

Three years ago, Redefine Meat started developing 'new meat' using 3D printing technology. "We started our adventure with the thought: 'meat is so tasty, you can't just take it off the menu'," says Edwin Bark, senior vice president of the young company. " Besides, eating meat is deeply rooted in our culture. But we could do with less of it. Is it possible to make 'new meat'?" The challenge; to make a substitute that is generationally sustainable, does not cause animal suffering and does not affect the biodiversity of our planet, was hardly new. Or was it? "We wanted to make a substitute that has exactly the same mouthfeel, taste and 'baking experience' as meat."

After more than three years of research and development, the founders succeeded in bringing a plant-based steak in one piece to the market. Chefs from top restaurants around the world are deeply impressed with the result. In the Netherlands, Ron Blaauw among others has put the vegetable steaks on the menus of his four Gastrobars. "But our ambition goes beyond conquering a position in the high-end service channel," says Edwin. "We are driven to really fix the food system. We can only achieve that by making an impact, meaning that we are present where meat is consumed; including in the supermarket. We focus on the diehard carnivore who doesn't want to give up anything, by far the largest group. And also the most critical, by the way.

Edwin bursts out laughing. "Yes, I've heard that too! I don't take that message very seriously. The vegetable meat market is now about 6-7 billion worldwide, the meat market 1.4 trillion. Analysts say that the current plant-based meat alternative market could grow to 140 billion in the next 10 years. Of course, it is not a wild idea at all to expect that 10 percent of our meat consumption in 10 years' time will be filled by plant-based meat substitutes. Consumers are hungry for innovation."

"The growth market did attract many new entrepreneurs. We see a clear increase in quality in the category, but unfortunately also offerings that are, let me state it kindly, mediocre. The main reason for consumers to abandon a product after trying it once is 'bad quality'. Brands that do not have enough resources to invest in new technologies, recipes and ingredients to improve their products are therefore a risk to the entire category."

"There is an enormous amount of research behind it. Of the current 140 employees, 70 are working in R&D. Our company is built on three pillars: technology, science and cooperation with chefs. Bringing all these competences together allows us to create plant-based meat that is similar to animal-based meat in every way: in taste, mouth feel, cooking experience, colour, cutability - everything. To do so, we analysed meat in great detail. Our focus was initially on beef, the most sold and most polluting piece of meat worldwide. This is where the most sustainability gains can be made. One kilo of beef requires 25 kilos of feed and 20,000 litres of clean water - it is extremely inefficient. At the same time, beef is also the most complex of all structures.

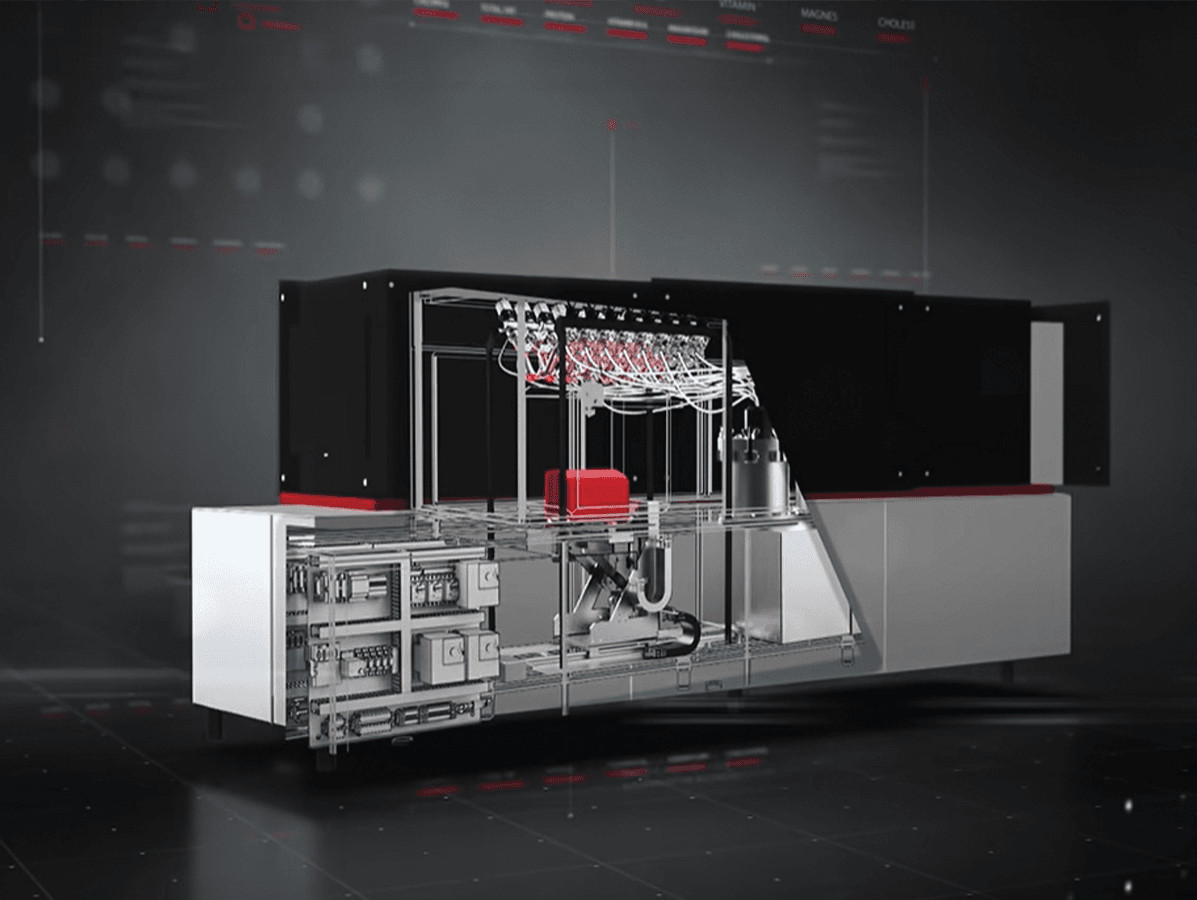

"Layer by layer, we recreate the meat structure very precisely using 3D printer technology. We call this the 'Meat Matrix Additive Manufacturing Technology', which enables us to create vegetable blood, fat and muscle tissue. The great advantage of this technology is that it is accurate, flexible and scalable. When we started, at the end of the day we had 1 kilo of new meat. Now, we make 10 kilos an hour. We can probably soon scale that up to 30 kilos an hour. We are also applying other technologies; our scientists are investigating all the possibilities. They are also researching locally grown ingredients; which ones could we use in our products, and how? In all the regions where we intend to establish ourselves, we want to set up local R&D teams that work as satellites of the central team in Israel. Collaboration with chefs, butchers and others is essential for R&D. By doing so, we will jointly develop products that are in line with the culinary culture of the respective region."

"The main ingredient is soya. Because this is a nutritionally sound ingredient with an almost complete amino acid profile. Its digestibility is good, it is available and it has good product properties for processing. That some people think that you contribute to rainforest deforestation by eating soy is nonsense. That is about soya for feed. The soya for human food is grown mainly in Mid-West America and China. Other ingredients we use are peas and chickpeas. All our products are vegan."

"The choice for the Netherlands was a very conscious one. The Netherlands is the European leader in terms of consumption of plant-based meat, with the highest per capita consumption of plant-based meat alternatives. In Wageningen we have the best university in the world in the field of Agri&Food, a friendly entrepreneurial climate and a great infrastructure. From here, we can supply many countries within a day. We first focus on the Netherlands itself, then the UK and Germany. The UK because it is absolutely the largest European market for vegetable meat, Germany because it has the largest population in Europe."

"That we chose the former Van Loon factory is partly due to the existing infrastructure in that building. It is excellent, from food-grade walls to the cooling systems. Hardly anything needs to be demolished or destroyed. Reuse is more sustainable than new construction. The owner of the premises is also working out a sustainability plan for the building."

"Yes,... but I have been a flexitarian for a very long time. After my studies, I consciously decided to eat much less meat. Because I don't need so much, it's not animal-friendly and there are so many great dishes that don't involve meat. I only eat it when I'm visiting someone and they've used it in their dish. I won't prohibit anyone from eating meat; that would only backfire.

"For a long time I wanted to do something to restore the balance of our food system. If we do nothing, an enormous amount of misery will befall us. How can you, as an individual, contribute to change, even if it is only in a tiny way? That is what I'm trying to do as much as possible in my daily life. I often talk about it with my children; they probably get very tired of my lectures from time to time, haha."

"It was my dream scenario to work in an industry that makes a positive impact in terms of sustainability and grows fast. I have succeeded. And I work with very talented people, it's hard to imagine a better situation. I expect that vegans will show little interest in a product that is fleshy like ours. The sweet spot is the real meat-lovers, the people who think sustainability sounds interesting, but when it comes down to it they don't want to give up their piece of meat. These are the people we want to win over. I hope they taste it and say: This is not a compromise! This is delicious! And, hey, I'm even doing something good for the world. If we manage to do that, we will achieve volume. That is when we make an impact.

Who is Edwin Bark?

As a Senior Executive, Edwin has 25 years of experience in the Consumer Goods Industry. His category expertise ranges from Food & Agritech (Nestlé) to Personal Care (L'Oréal) and Consumer Healthcare; both in corporate and entrepreneurial (private equity) companies. He is also an advisor for several Foodtech companies and a mentor for StartLife.

Photos: ©Herbert Wiggerman

Source: Vakblad Voedingsindustrie 2022