Digitally controlled food production enables innovations that were, until recently, unheard of: personalised food, vegetable protein with the bite of meat and new shapes, tastes and structures with 3D food printing. “Digital techniques will drastically change the food production chain”, Joost Blankestijn expects. He’s Programme Manager Food Innovations for Responsible Choices at Wageningen Food & Biobased Research.

In his function, Joost Blankestijn is focused on four main directions: reuse of waste flows, shelf life management, development of clean label and new food structures. He is also closely involved with the new ‘Digital Food Processing Initiative’ (DFPI) that was officially launched on July 29th of this year in Wageningen. DFPI is an initiative of Wageningen University & Research (WUR), TNO, AMSYSTEMS and Eindhoven University of Technology.

‘Especially the companies in the layer directly under the multinationals are fully investing in product and process innovation.’

Before this, Joost worked at TNO Zeist for years. In January of this year, TNO’s search group Functional Ingredients became part of Wageningen Food & Biobased Research. “We already collaborated on a lot of projects the last few years”, Joost explains. “The transition of TNO to Wageningen was therefore not a huge one to me. What I do like is that Wageningen is alive with inspiration and innovation. That’s because it’s close to the campus, the university and doctoral research and the R&D departments of Unilever and Friesland Campina. That makes me very enthusiastic.”

“With the move and transition to the TNO Functional Ingredients group from Zeist to Wageningen, the collaboration with TNO Eindhoven was less of a given. This collaboration did once form the foundation for research on and the development of 3D food printing in the Netherlands. It was our strength to use knowledge of the technical equipment in close collaboration with food science for these unique developments. The collaboration with Wageningen opens up an even more extensive knowledge base to further implement the technology. Think of, for example, the expertise regarding consumer research. This will provide us with understanding surrounding the acceptation of 3D printed food.”

“The ambition of the Digital Food Processing Initiative goes beyond just 3D food printing. With this consortium, we want to help food companies gain insight into the possibilities of all digital techniques and high-tech systems for food, so it enables them to use this innovation and translate it to use on the market more swiftly. The combined expertise of food and digital technology makes the consortium unique to Europe.”

“These are mostly Public-Private Partnerships (PPP) in which we work on innovation. Leading sector Agri&Food is one of the 9 leading sectors. The government has decided we must remain competitive in these sectors and invests in it. In the PPPs, companies and knowledge institutes participate with public and private money, to reach innovation together and attain general knowledge, so the Dutch sector can maintain its prime position. For the project ‘Alternative proteins for outstanding meat analogues’, for example, I try to get the entire chain together: producers of ingredients, end producers and equipment builders to quicker establish innovation. It’s good to know that the knowledge and results of a PPP become the property of the knowledge institutions. If you want to keep the knowledge as a company, you naturally can. In this case, we make agreements in advance about the exclusivity of the results of the research. You do lose state aid in doing so.”

“To achieve sustainability goals, you need a lot of innovation. Reusing waste flows is a way to make processes more sustainable. We research, for example, how we can gain as much value out of waste flows within the agri-food sector. Early this year, the PPP ‘CULTURED’ was set up in which eight companies from the entire food production chain, from ingredient suppliers to manufacturers of end products, collaborate on, among others, getting value out of the waste flows from the primary sector, using fermentation. Can we, for example, produce natural flavours, sweeteners and preservatives by fermenting waste flows? The components formed by fermentation can then be applied to foodstuff. We expect a lot of innovation in the upcoming years using this ancient technology, particularly because the consumer is so familiar with it. Cheese, yogurt and beer are products that have been produced by fermentation for a long time. The pressure on the industry to produce products with a ‘clean label’ increases. Fermentation can provide a solution.”

“Sustainability is also a reason for innovations in shelf life management. How can you preserve a product for longer and which natural ingredients, like herbs and spices, are suitable for this? A nice example from the past of such a collaboration is the project of experts of Wageningen Food & Biobased Research with Hoogsteger. Together, they developed and implemented a mild conservation technology that is based on PEF (Pulsed Electric Field). The last few years, efficiency of Hoggsteger’s process has doubled thanks to this collaboration.”

In this, digital techniques play an increasingly large part. Not just 3D foodprinting, but also, for example, the shear cell technology is controlled by the computer. And so is making pre-packaged pancakes in the supermarket.

‘The ambition of the Digital Food Processing Initiative goes beyond just 3D food printing’

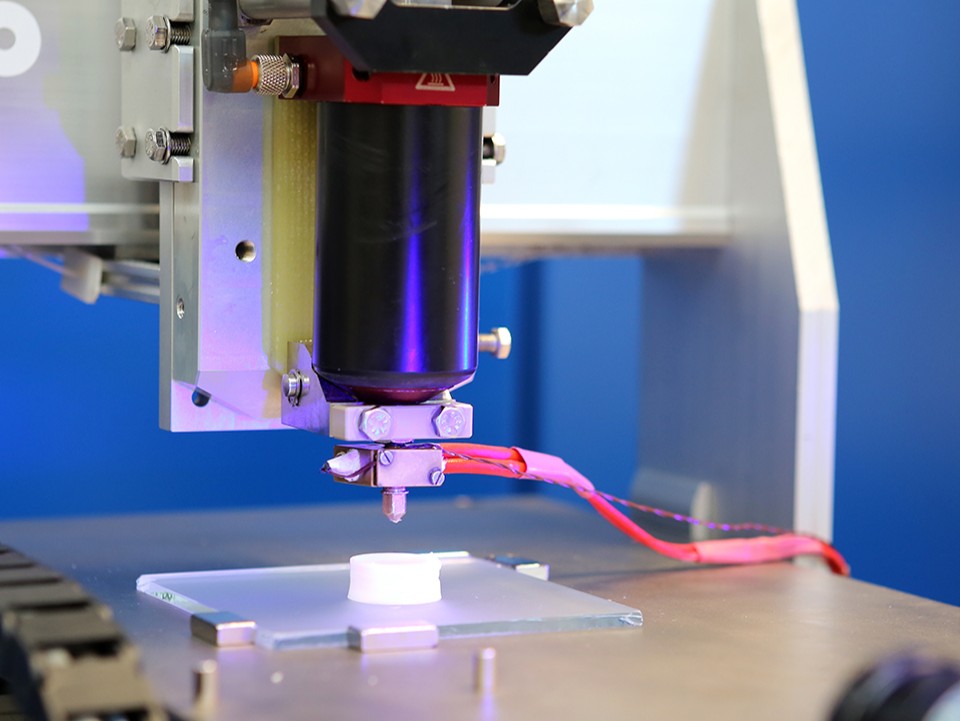

What has been achieved with 3D food printing so far are mostly funny applications. Behind the scenes, however, the technology has continued to develop considerably. From a machine bound together with tie-rips that can only hold one cartridge to the much more advanced 3D food printing machines of now, that are suitable for printing multiple liquids and powders are the same time. We’re capable of printing very intricate forms and structures. Translating it to the market is already starting to happen. In technology, we’re global frontrunners in the Netherlands, collaborated and still collaborate with large companies like Barilla, Verstegen, the CandyFactory and Bosch Siemens. We’re at the beginning of a massive development. So much is happening.”

“Correct, this direction isn’t new but the innovations are. Incentive for innovation is the pressure from society, sustainability requirements and changing laws and regulations. Until now, the industry was self-regulating in reformulating their products. I expect this will change, because the current state secretary is very clear that lowering the amount of salt, fat and sugar in products is happening fast enough. He thinks that the goals should be more ambitious and will implement higher standards. To help companies in this the Ministry of HWS continues a pilot project that started last year. Through the FNLI (Federation of Dutch Food Industry), the industry could file a request for a consultation by an expert of Wageningen Food & Biobased Research of NIZO. Companies can now register again using FNLI. The expert will assess what the company has already done, will inform themselves, examine what problems the product developers are facing, visits the company, analyses the production process and provides advice. That advice is usually enough for the company to take the next step. Should they not manage, then they can use the services that the knowledge institutes offer.”

“Our independence is our greatest asset in this. We are not bound to any company or supplier, we’re looking for the most optimal solution for the company. For this, we have the most advanced analysis equipment at our disposal, which we can, for example, use to measure what the effect is of a change in the recipe on, among others, baking behaviour, taste and structure of the product.”

“I am very positive about it. Especially the companies in the layer directly under the multinationals are fully investing in product and process innovation. In this category, there’s the defining factor of “If I don’t get on the bandwagon, I’ll end up missing out”. They have the flexibility to start new movements. This is harder for the big multinationals.”

“I expect a lot of 3D food printing. We’re in talks with parties in retail and out-of-home, with caterers and producers of end products. They all see potential and expect that in time, the technique will lead to new products. How long this will take is very hard to determine, but increasing scale is definitely in the cards for 3D. It’s already possible for a nursery home to print 200 meals a day. Meals that are suitable for people with chewing and swallowing issues and are personalised, therefore made with the ingredients and nutrients that a specific person needs.”

“I also expect a lot of innovations of reformulating, a very relevant subject society-wise. Much more can be done regarding the lowering of sugar, salt and fat. The world of bakeries is collectively collaborating on a structural lowering of salt in bread. Bit by bit, they managed to lower the salt level 25% and no one has noticed the difference in taste. If other branches collectively get to work on this, so much more can be accomplished.”

“In translating innovations to use on the market. This is why the business case is so important, why we want to collaborate with companies. They can indicate what they need so we can take the next steps. We can properly map possible solutions.”

For questions about collaborative projects, those interested can contact Joost Blankestijn: [email protected] or Daniel van Linden van TNO/AMSYSTEMS: [email protected]

Source: © WUR