Vision Partners continues to innovate with advanced in-line analysis technologies that make industrial processes more efficient, accurate, and sustainable. By combining cutting-edge sensor technology with intelligent data analysis, Vision Partners helps companies across various sectors gain real-time insight into product quality and process optimisation. Two recent developments—the in-line determination of the chemical composition of natural products such as animal fat, and in-line 3D height and width measurement—demonstrate the impact of these technologies on industry.

The food and animal feed industries face strict quality standards and complex production systems. Vision Partners has developed an innovative in-line technology that enables the chemical composition of animal fat to be analysed directly during processing. This prevents deviations in product quality, reduces production costs, and minimises waste.

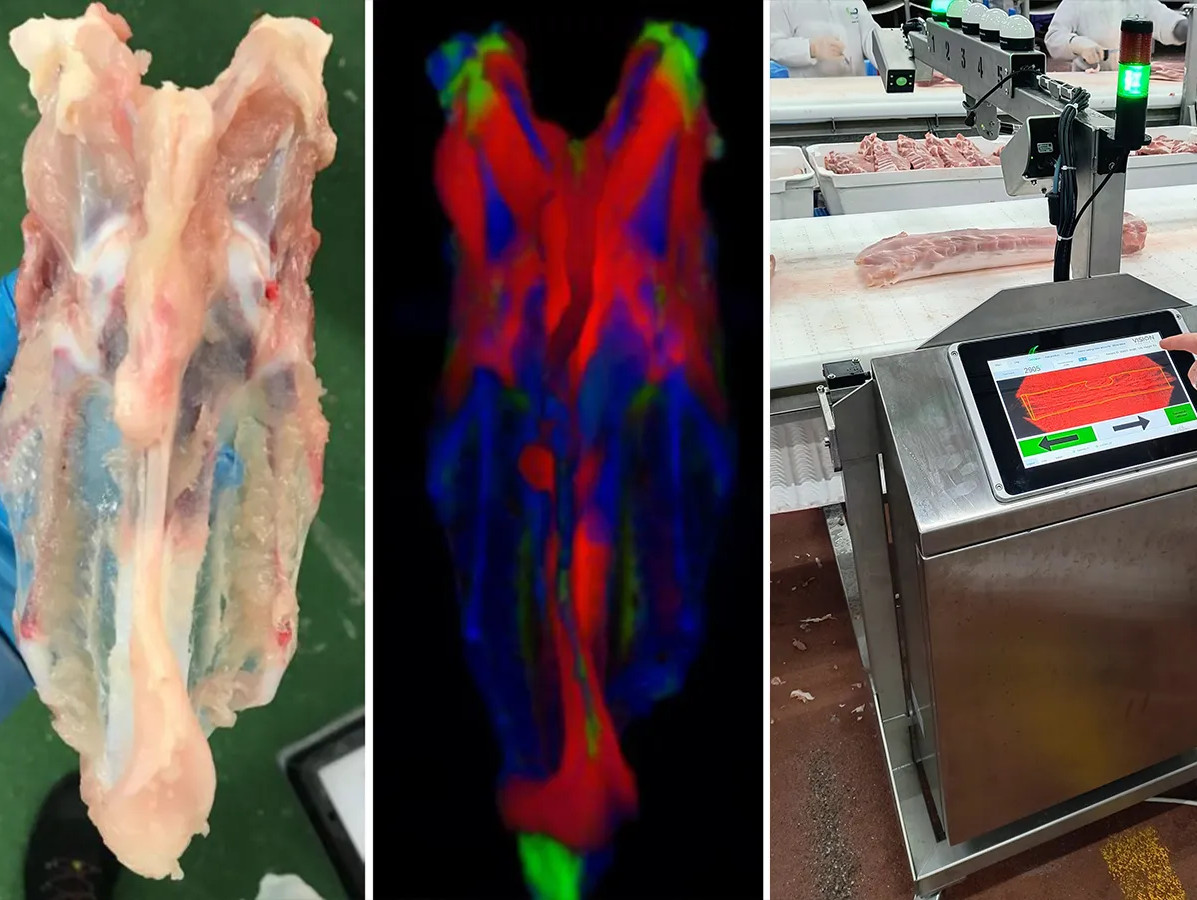

Using advanced spectroscopic techniques, the fat is continuously analysed for parameters such as fatty acid composition and purity, without interrupting the production flow. This provides manufacturers with direct control over their processes and allows for timely adjustments. Unlike traditional sample-based testing, which can be time-consuming and prone to error, this in-line technology ensures consistent quality monitoring and process optimisation.

In addition to chemical analysis, Vision Partners offers advanced measurement solutions for industrial production processes. The in-line 3D height and width measurement system was developed to monitor and classify products with high precision during production. This system uses advanced 3D optical sensors to scan and analyse product dimensions in real time.

For industries such as food processing, this results in significantly improved process control and product quality. By continuously measuring height and width, manufacturers can detect deviations before products leave the production line. This helps prevent material waste, reduces costs, and improves production efficiency.

Vision Partners’ technologies respond to the growing demand for smart, automated quality control systems. By integrating sensor technology and data analysis, companies can optimise their processes without adding labour costs or complexity. This contributes to a more sustainable and cost-efficient production environment.

“Our mission is to make industrial processes smarter and more effective through the application of advanced in-line technologies,” says Jeroen Keunen, General Manager at Vision Partners. “With these innovations, we help companies optimise their production and strengthen their competitive position.”

For more information about our solutions and applications, visit www.visionpartners.nl

Food Tech Event 2025 | Hall 3 Booth 71

Source: Vakblad Voedingsindustrie 2025