Accurate measurements are important, in both the design and the construction process. A lack of reliable data on the existing building can result in errors in extension or renovation plans. 3D laser scanning offers a way forward.

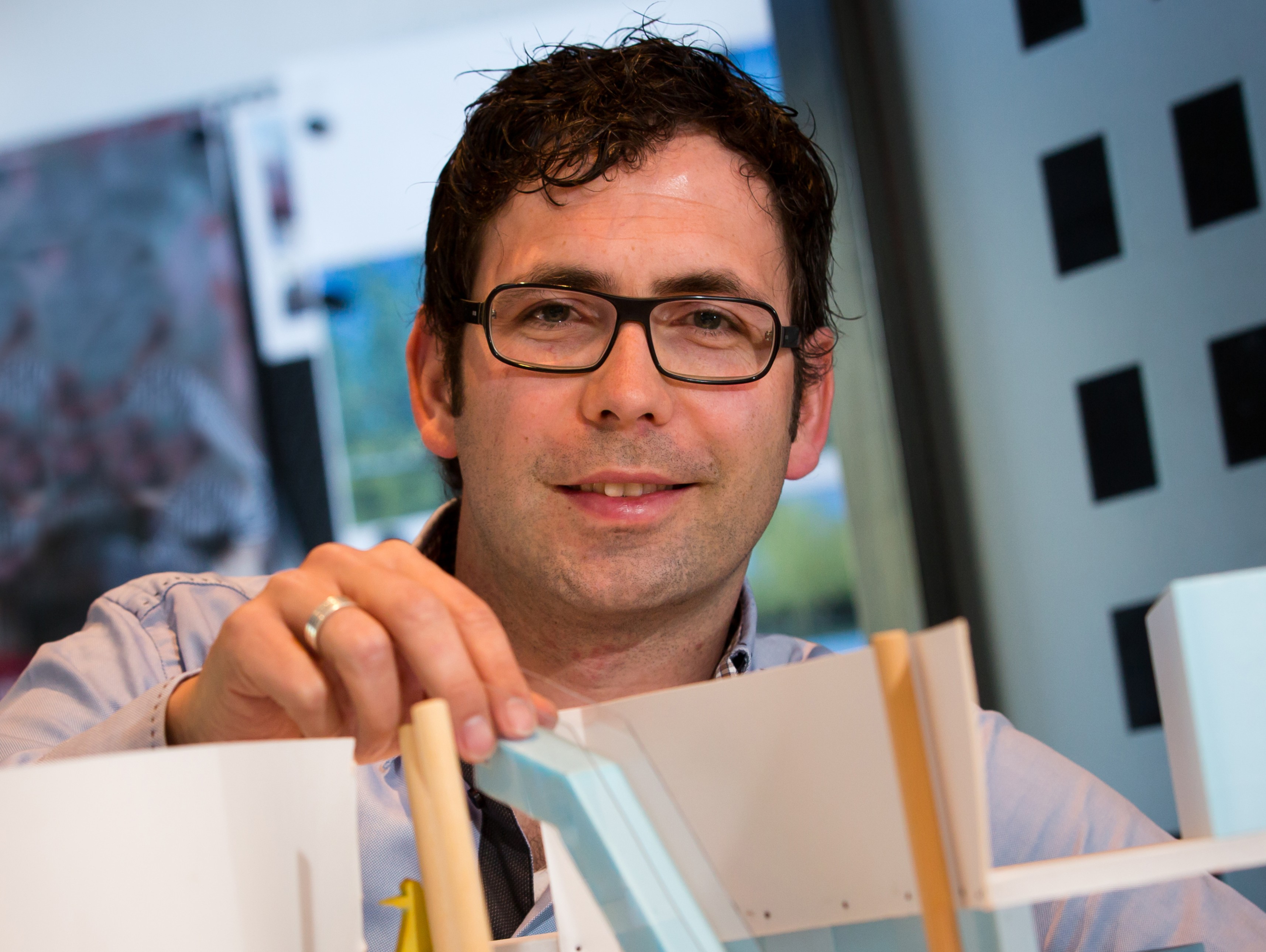

“The later such errors come to light, the more costly it will be to rectify them. Ideally, precise measurements should be available as early as possible in the planning process. After all, to measure is to know,” says Bram van Gurp, project manager at Bessels Architekten & Ingenieurs B.V. based in the Dutch village of Twello. “There is often only very limited documentation available of existing buildings,” he continues.

“And even if all the original construction drawings can be found, they tend not to be detailed enough. Often, accurate measurements are severely lacking, plus there’s no guarantee that the building has been constructed completely in line with the drawings. Normally, the only option is to re-survey the existing building.”

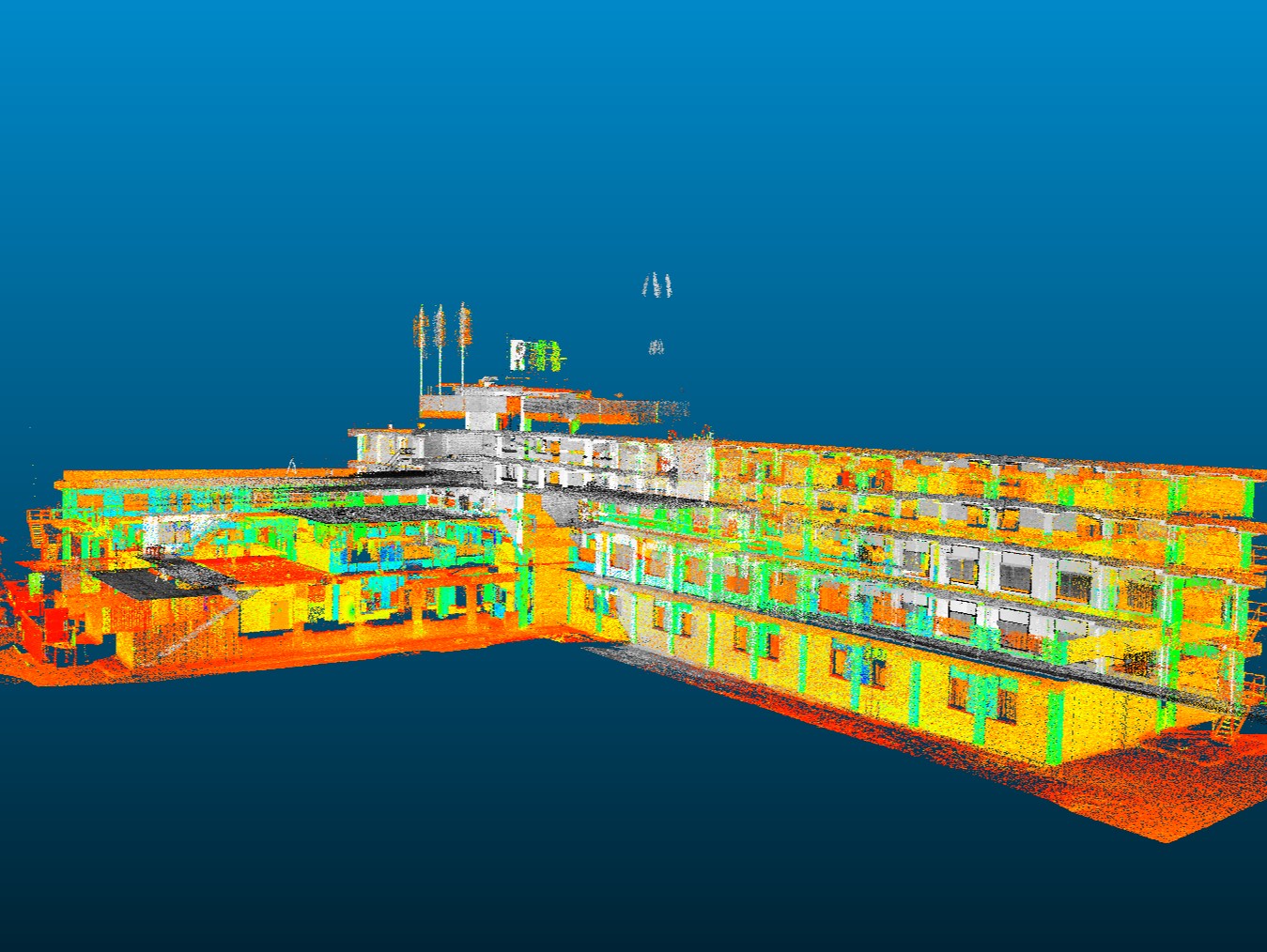

Whereas measuring used to be done manually, nowadays Bessels Architekten & Ingenieurs B.V. often surveys buildings, installations and other objects digitally with the aid of a 3D laser scanner. “A laser scan can accurately capture the as-built situation,” explains Bram. “The 3D laser scanner utilises the way a laser beam bounces off an object to determine the x, y and z values. A realistic model of the object can be produced by generating many different measurement points – sometimes hundreds of millions of them in the case of large buildings.” However, the entire building does not have to be scanned in one go. Instead, point clouds can be used, which are collections of reference points containing a huge amount of coordinates. Using the coordinates, individual point clouds can be combined to produce a single model.

A laser scanner cannot scan through obstructions. Bram: “The laser scanner can only measure what is in its line of sight, i.e. what the laser beam can reach. Therefore, the scanner will need to be repositioned several times in order to be able to ‘see’ and hence survey the complete building structure. Doors and windows will also have to be opened in order to be able to connect exterior scans with interior scans.”

The point clouds are put into architectural modelling software where they serve as the basis for a 3D model of the building. “This allows our architectural modellers to make complete as-built 3D models of complex existing buildings. BIM (Building Information Modelling) enables all those involved to use the same digital 3D building model, which means that everyone is working with the same data. Other opportunities include visualisations, video animations and virtual tours. The key benefits of this 3D approach are better alignment, improved error detection and time savings.”

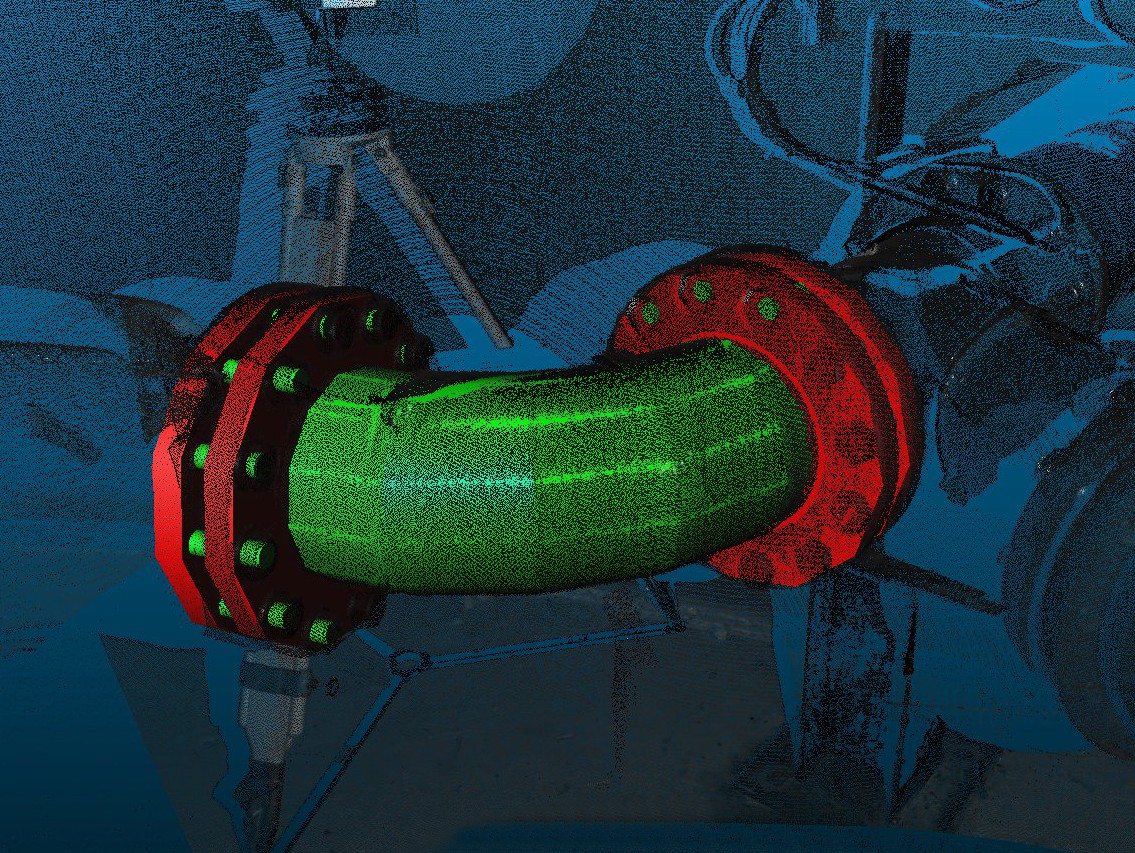

3D laser scanning can also be used for industrial purposes, such as to gain an overview of an industrial plant or plant room, pipes and technical rooms. “The data from a scan not only provides information about the existing situation but also offers insight into expansion opportunities,” says Bram. “By combining the 3D point cloud of the existing installation with the design of the new sections that are to be added, we can identify any potential conflicts. Detecting these in the design phase means that the subsequent construction phase runs more smoothly, and error costs are avoided. ‘As built’ meets ‘as designed’!”

Source: Bessels