Both from a food safety perspective and in view of the current financial crisis, food processing companies are paying increasing attention to the cleaning process. How can they save costs without jeopardising the safety of their food products? By considering the cleaning aspect before setting up the production line, it is possible to get a step ahead.

More and more companies in the food processing industry are realising that cleaning is inextricably linked with food safety. Whereas the motto used to be ‘Production first, cleaning later’, this has generally evolved into ‘Cleaning first, production later’. The cleaning plan is no longer the last thing on the manufacturing overhead budget. Processing companies and cleaning companies who are not only aware of this fact but also have the necessary in-house expertise to be able to create the right preconditions can benefit in terms of quality, operations and finance by taking the next step: by starting with the right approach to the cleaning process.

HACCP and FSSC22000 provide the basis for a thorough risk analysis to safeguard food safety. Additional criteria from AIB, IFS and BRC result in a list of minimum requirements for the cleaning process. The extent to which a batch of potatoes must be sand-free after being cleaned at a fries manufacturer, for example, is a matter of choice. Nevertheless, it is a decision that is included in a cleaning plan – a document outlining what, why, when and how equipment must be cleaned, and to what standard. It is definitely a case of ‘Cobbler, stick to your last,’ because cleaning is a skill in its own right! There are even different specialisms within the cleaning sector: an operator of intestine cleaning equipment in a slaughterhouse would probably not feel at home in a high-care packaging environment for dried milk powder, for example.

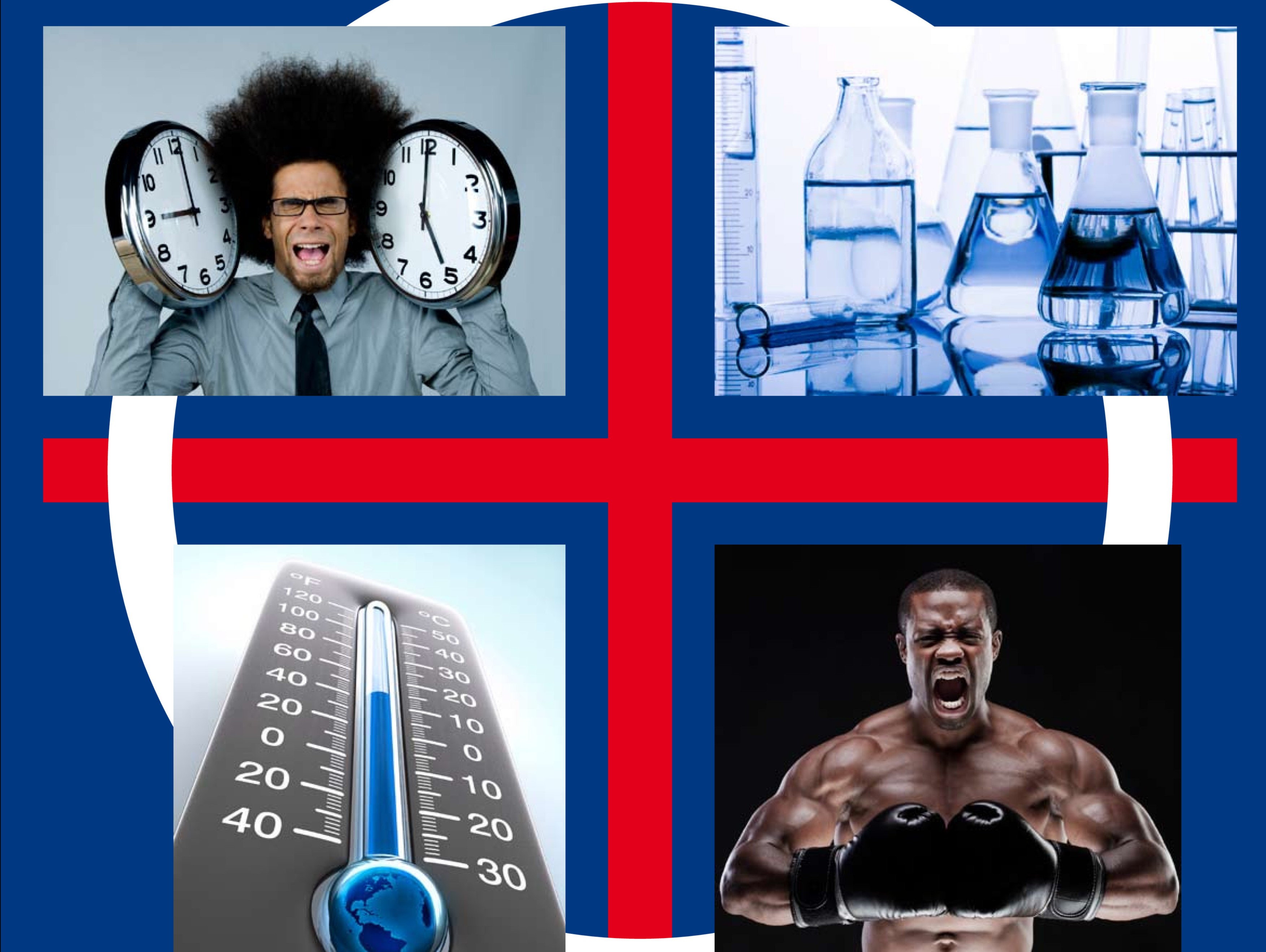

The Sinner Circle: the parameters of time, chemicals, mechanics and temperature must be perfectly balanced.

To answer the ‘how’ part of the cleaning question, i.e. the best way of removing dirt or impurities from a particular surface, it is necessary to understand the production process and to apply the ‘Sinner Circle’ (see image): time, chemicals, mechanics and temperature. If one element is reduced, one or more of the others must be increased to compensate. This equilibrium can be affected by many factors, such as the stability of the high-pressure pumps in the case of several users, the pressure level, the type and degree of contamination, the ambient temperature possible within the company, the availability of water for cleaning, and the correct chemical composition. All of these aspects must be taken into consideration.

Nevertheless, this does not guarantee successful cleaning and disinfection. The activity of cleaning and disinfecting a production line is time consuming and often done manually – i.e. by people. Well-trained and motivated employees, combined with the right management and supervision, make all the difference. Moreover, it is possible to considerably raise the motivation of cleaning personnel by involving them in optimising the cleaning process, such as by allowing them to participate in improvement programmes and be part of improvement teams. Intensive collaboration can deliver significant cost savings, thus reducing the cost price of the end product.

It is also possible to achieve impressive results by switching from high-pressure to medium-pressure cleaning and disinfecting. The benefits of this approach include a drastic reduction in airborne (microbiological) spread of contamination, damage to equipment and energy consumption. Other innovations include the relatively unknown technology of dry-ice blasting. Luckily, when it comes to quality assurance and ‘making things easier for people’, technology is advancing all the time. Industrial cleaning and disinfecting is becoming ever-more automated, and smart solutions are making cleaning in the food industry ‘sexy’ again.

Cleaning and disinfection are essential to guarantee safe food products, and production line design plays an important role. The equipment guidelines include the criteria for cleaning a machine. Unfortunately, due to a lack of space or money, different (i.e. wrong) choices are often made: a machine might be installed too close to another line leaving insufficient space for effective cleaning, perhaps suboptimal materials are used, or certain parts of the machine are difficult to reach. The EHEDG guidelines are an indispensable tool for hygienic design. Following these guidelines when building machines enables many hygiene-related risks to be eliminated. Adapting a production line after it has been installed can be expensive and does not necessarily reduce the cleaning time significantly, so it makes sense to think about optimal cleaning while still at the machine design stage. Even if that makes the production line more expensive, the extra investment will soon pay off, not only in terms of lower overhead costs for cleaning but also with safer food products.

Hago Food & Industry

Hago Food & Industry is a business unit of Hago which is dedicated to the cleaning of industrial environments. Hago Food & Industry combines the robustness of a nationwide organisation and strong back office with 70 years of specialist knowledge and experience in the food industry, the chemical industry and in high-tech production environments. Hago Food & Industry puts its expertise to good use on a daily basis on behalf of leading industry names. Hago Food & Industry is part of Vebego, a prime example of a family-run company that makes highly skilled employees one of its top priorities.

www.hagofoodandindustry.nl

Source: Vakblad Voedingsindustrie 2014