May is a busy trade show month for the food industry, with both IFFA and Food Tech Event 2025 on the calendar. Be sure to visit the Stäubli Robotics booth and see how food manufacturers are increasing productivity with our uniquely designed food-grade robots—while continuing to meet strict safety and quality standards.

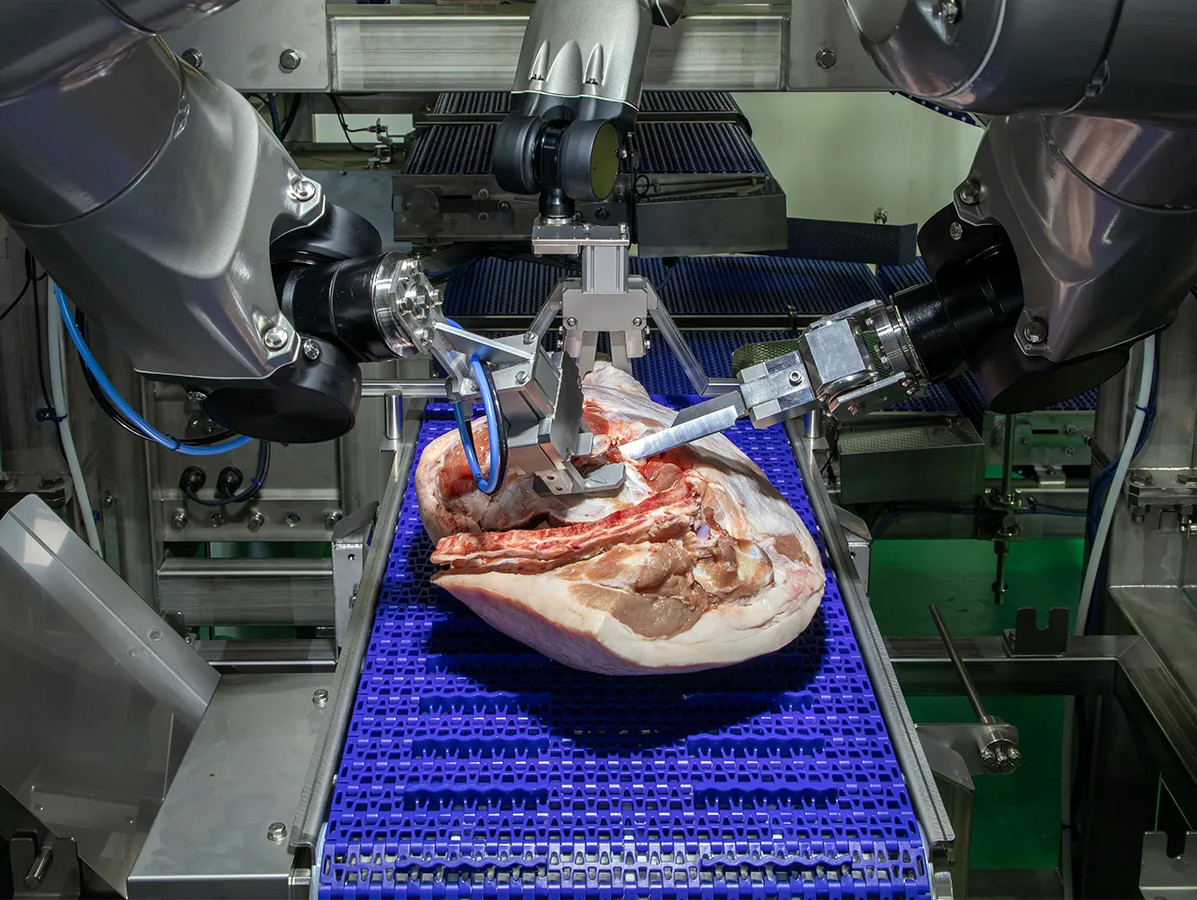

At both events, we’ll demonstrate two Stäubli robots: a TX2-60 HE and the Red Dot Award-winning TS2-60 HE, both using conveyor tracking technology to cut and handle raw meat. The TX2 uses a waterjet cutter to simulate portioning meat and placing it on a conveyor. Once the camera detects the products, the tracking application signals the TS2 to transfer them to a packaging unit.

At IFFA, we’ll also present a second demo: high-speed tracking of ready meals with chicken. A TS2-80 HE robot uses a vision sensor with a SensoPart camera to precisely detect the products. It then carefully grips the chicken pieces using a food-grade SoftGripping gripper to quickly and accurately fill the containers.

The robots' ability to handle viscoelastic and fragile foods while preserving product shape and integrity highlights their exceptional control.

To support the complex workflows of the food industry, Stäubli Robotics offers a complete portfolio of HE (humid environment) robots. These systems are built to maintain process reliability in demanding conditions.

Equipment used in the food industry must meet strict standards to avoid contamination and ensure food safety and quality. Stäubli’s food-grade robots comply with European Hygienic Engineering & Design Group (EHEDG) guidelines for hygienic design, widely considered the gold standard.

HE robots operate with dynamic precision during the cutting process. They are designed to perform over long periods in wet and humid environments.

Stäubli Robotics offers a broad range of services and training options, including global on-site repair services to ensure rapid response and maximise robot uptime. Our systems achieve an availability rate of 99.95%.

Comprehensive service, support, and training help customers safeguard their investment—on top of the gains in efficiency, productivity, and product quality. Stäubli robots are energy-efficient and offer the best-in-class lifespan for use in harsh and sensitive environments such as food production. Their hygienically sealed design enables faster cleaning without the need for external covers. Oil changes are also simplified thanks to the integrated Stäubli CBI fluid connectors.

Food Tech Event 2025 | Hall 3 Booth 67

IFFA 2025 | Hall 12.0 Booth D31

Source: Vakblad Voedingsindustrie 2025