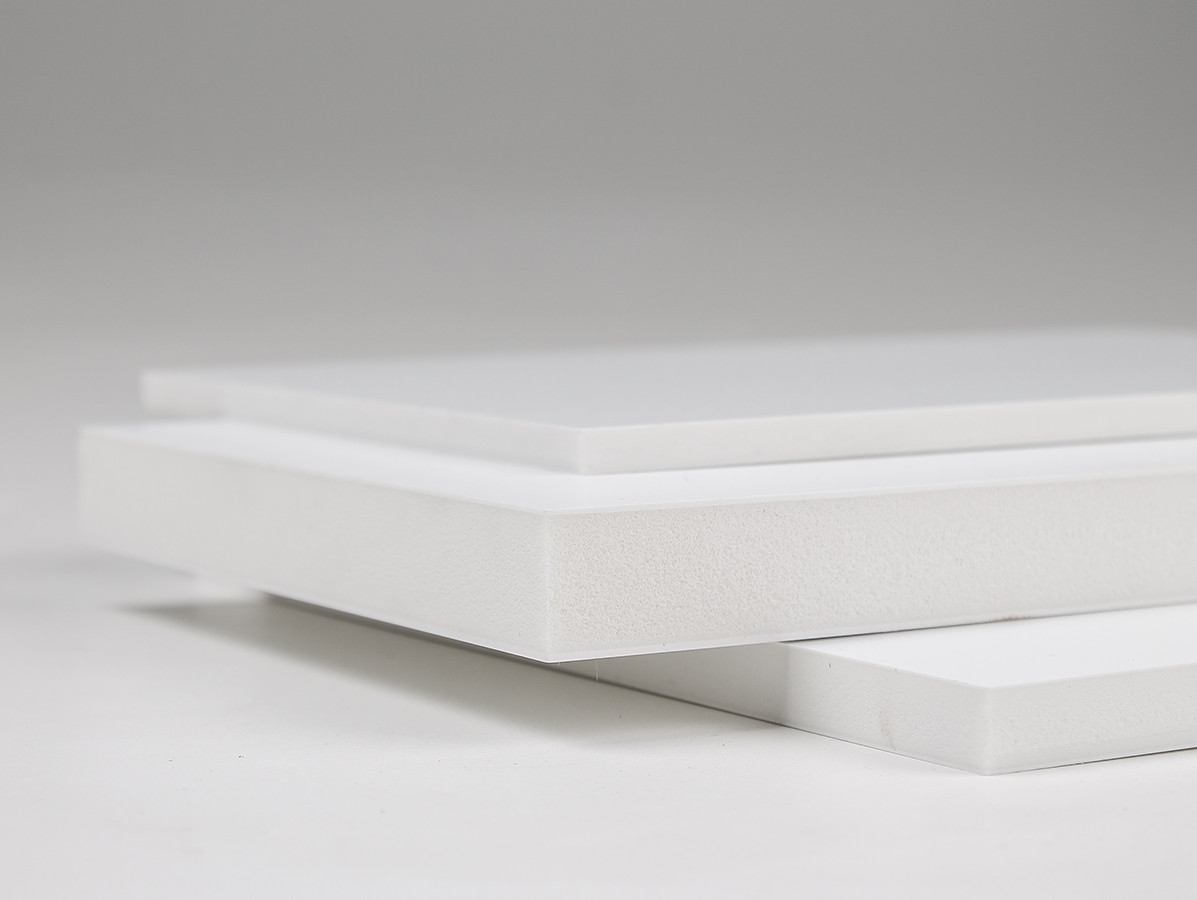

Forget mdf, plywood or chipboard! Discover Sealwise WCB; circular and fully waterproof panels made of recycled PVC.

Sealwise WCB, because that's the name of the material, has a number of special properties, of which the absolute waterproofness and the anti-bacterial and anti-viral are the most remarkable. These are very important advantages in the food industry. Think of wall panels in the production environment, changing rooms, clean rooms and laboratories, but it is also very suitable for furniture in these environments.

"The panels are made using the Biomaster® method; a technology in which silver ions are incorporated through and through in the material and are therefore an integral part of the panel," says Ernest Conradi, manager of Sealwise Netherlands. "This prevents bacteria and viruses from growing, producing energy or replicating, causing them to die. It has been proven that the material reduces bacterial growth by 99.9% and, as recently discovered, virus growth by 99.8%. A renowned laboratory in England showed that the beta virus of COVID 19, applied to Sealwise, had almost completely disappeared after just two hours. Other viruses were also tested for it, including influenza, measles, dengue fever and SARS viruses," says Ernest. "Sealwise is the only plate material with this exceptionally high score. Keep in mind that viruses in the food industry can survive up to 72 hours on a widely used material such as stainless steel."

A patented closed cell technology, in which millions of tiny vesicles are fused together, guarantees absolute watertightness. "At the beginning of the production process, the material is a liquid, warm mixture," Ernest explains. "This substance is carefully monitored; we meet the highest tolerance requirements". Combined with the silver ion technology, the closed cell technology prevents contamination by harmful bacteria and viruses, infestation and unpleasant odours. "It's completely safe; you can't see, smell or taste Sealwise WCB anti-bacterial", emphasizes the manager. "Cleaning the walls is quick, easy and thorough. It has excellent resistance to chemicals, which we have tested extensively. We test the material according to the ISO standards at all times and carry out continuous quality checks. We represent security".

The panels are easy to place over existing (tile) walls, fire resistant, thermally stable and extremely wear-resistant. "Should a scratch occur anyway? Then it is easy to repair it yourself. This can be done with heat, for example with a hairdryer or special iron, or by light sanding and polishing. Thanks to its long durability and minimum maintenance, the material offers an excellent return on investment".

For a long time, PVC had an environmentally unfriendly image. But technology does not stand still. "In fact, through new developments in the recycling process, we dare to say that WCB is one of the most sustainable materials in our industry," says Ernest. "It is largely made from recycled materials: UPVC, which contains no softeners. Together with the closed cell technology, this contributes to the stiffness of the material. The outer layer is made from new, unmixed PVC. The entire panel is fully recyclable after use.

Source: Vakblad Voedingsindustrie 2020