As a food producer/packer, you have undoubtedly done what the Packaging Waste Fund wanted you to do in recent years: you have worked on prevention (lighter, less, thinner) and paid attention to the Essential Requirements (EU Directive 94/62). But that's not enough: consumers, the government and your customers (retailers) expect more.

Wil Nijssen of Pack Improve works as an on-call packaging expert for food producers; for medium-sized companies as well as multinationals. "I work both operationally, for example by solving the daily packaging issues, and strategically by helping to define and formulate a long-term vision on packaging. Lately, many food producers have been struggling with the question: 'what is needed to ultimately arrive at a circular system with packaging? Many food producers are at the beginning of a new process: to devise alternatives to their current packaging, and to carry out research into their impact on the shelf life of the packaged products (and the prevention of waste). The machine processability and application of the alternatives must also be tested".

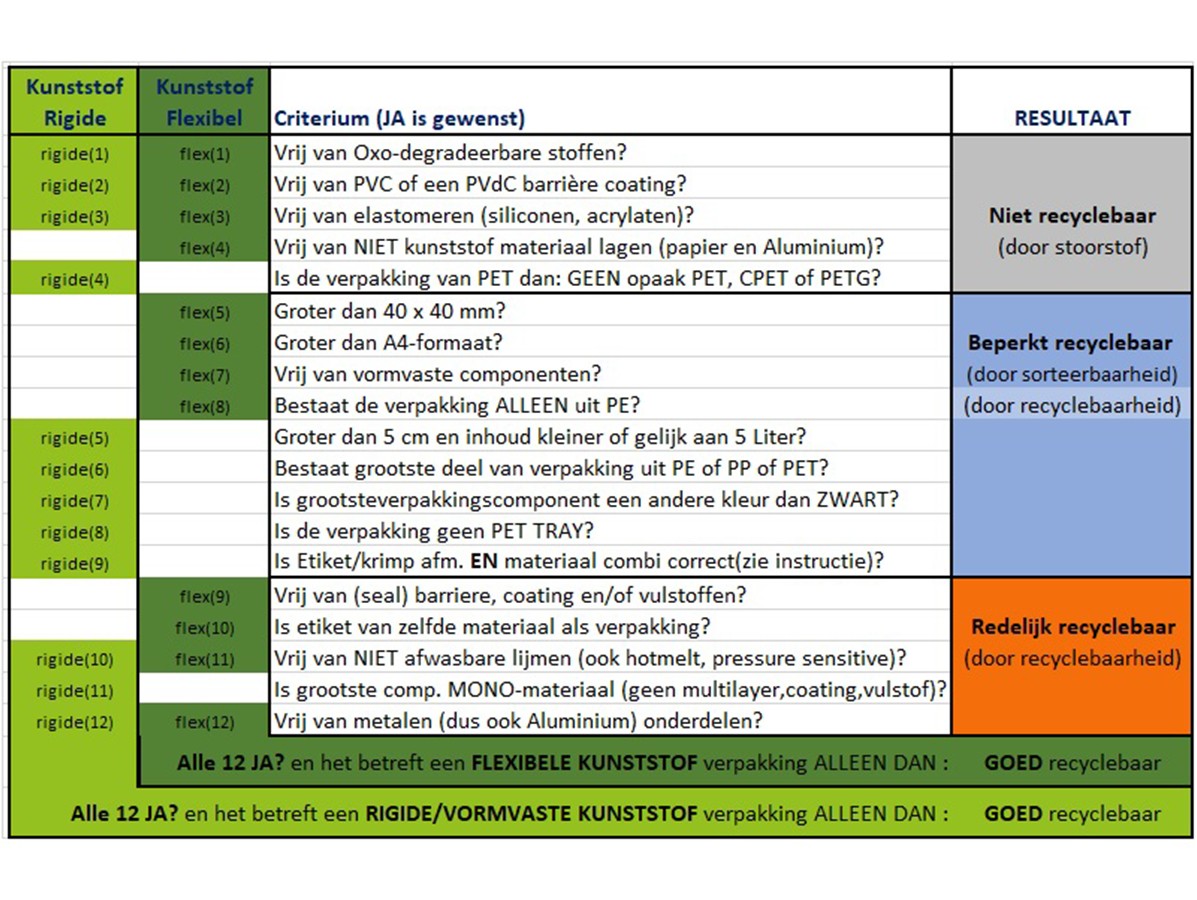

"At the moment, packaging uses a wide variety of plastics. Once mixed together on the rubbish heap, only low-grade recycling is possible. We also use multilayers or laminates, which are made up of several (barrier) layers of different plastics. This is functional and useful, but it also has a disadvantage. The layers are not separable, and therefore cannot be recycled". Pure material flows are needed to enable high quality recycling of plastics using current techniques. And for that, good (post)sorting is required. "Existing sorters can do a lot, but not (yet) everything", Wil continues. "Until a few years ago the focus was on 'theoretical' recyclability. Now the whole chain is involved and thinks along . There is a lot of consultation with each other to determine what plastic packaging has to comply with in order to actually be recycled. The approach has become more practical. When (re)designing the plastic packaging, packers are encouraged to take into account the technical limitations of the recyclers, but also so-called 'disruptive substances'. The Knowledge Institute for Sustainable Packaging (KIDV) has issued two guidelines for plastic packaging; for rigid packaging and for flexible packaging. In order to be awarded the designation 'highly recyclable', all twelve criteria must be met. Practice has shown that this is not yet easy for food packaging. If it does, the reward is a low rate of 34 cents/kg (instead of 60 cents/kg)".

Recycle guideline flexible and rigid plastic packaging

Wil continues: "Food producers prefer to package their products at the lowest possible cost and with an appropriate presentation, but above all to get them to the consumer fresh, undamaged and with as little loss of quality as possible. This makes packaging a sustainable operation: it prevents food waste and thus reduces the carbon footprint. The fact that the consumer mainly sees the 'plastic soup' and barely understands the function of packaging is understandable, but also makes it difficult. Still, it can't do any harm to continue to take a critical look at your product, its actual vulnerability and the entire supply chain. It makes sense to (re)examine whether the packaging as you currently use it is still necessary. Ask yourself the question: can it be done differently?

Polyolefins (known by abbreviations such as LDPE/ HDPE/ LLDPE/ PP/ BOPP and CPP) we preferably use as monomaterial. The potential for recyclability and quality of the recyclate is the highest in this group. For materials that consist for 90% or more of (different layers of) polyolefins, the potential for recycling is still better than for a laminate with PET, PA, etcetera. At the moment, only PE comes out of the PMD bag as new packaging, and then only as non-food packaging. Moreover, there are the necessary legal restrictions for the use of recyclate in new packaging that is in direct contact with food: ensuring food safety and care for hygiene are more important than recycling. It's not really circular yet".

"As a packer you have to make choices, dealing with three pillars: the consumer (and his separation behaviour), the recycling industry and the producers of packaging. All three are on the move", Wil points out. "The consumer is doing his best with the current source separation: glass goes in the glass container, paper and cardboard in the paper container, plastic and drinks cartons in the PMD bag. However, he should understand even better how you intended the producer to use the packaging, especially when it comes to sorting and separating; think of the plastic bucket with a wrap of cardboard around it. This is not always separated from each other and put into separate waste bins. In short: there is still plenty to do!

In order to achieve a circular system, it is important that companies follow the developments and take small (partial) steps forward. Wil: "The diversity in the packaging world is great. One comprehensive solution is not available. However, I do expect more and more best practices and standardized solutions to emerge".

Source: © Vakblad Voedingsindustrie 2020