Water activity (aw) is a crucial parameter in determining the food safety and quality of a product. However, it is crucial to note that achieving accurate and reliable measurements is essential! In this article, we shed light on important considerations and pitfalls when measuring aw values.

Wateractivity, with the parameter aw, is the measurement of the amount of ‘free water’ in a product. This measure provides essential information about the microbiological safety of a product. Microorganisms, in addition to nutrients and a suitable temperature, require water to proliferate. The lower the aw value, the more challenging it is for microorganisms to multiply, with each microorganism having its own threshold.

Additionally, water activity provides information about properties such as stickiness, texture changes, discoloration, and in the case of powders, it indicates the likelihood of clumping. Knowing this parameter of your product gives you control over its quality.

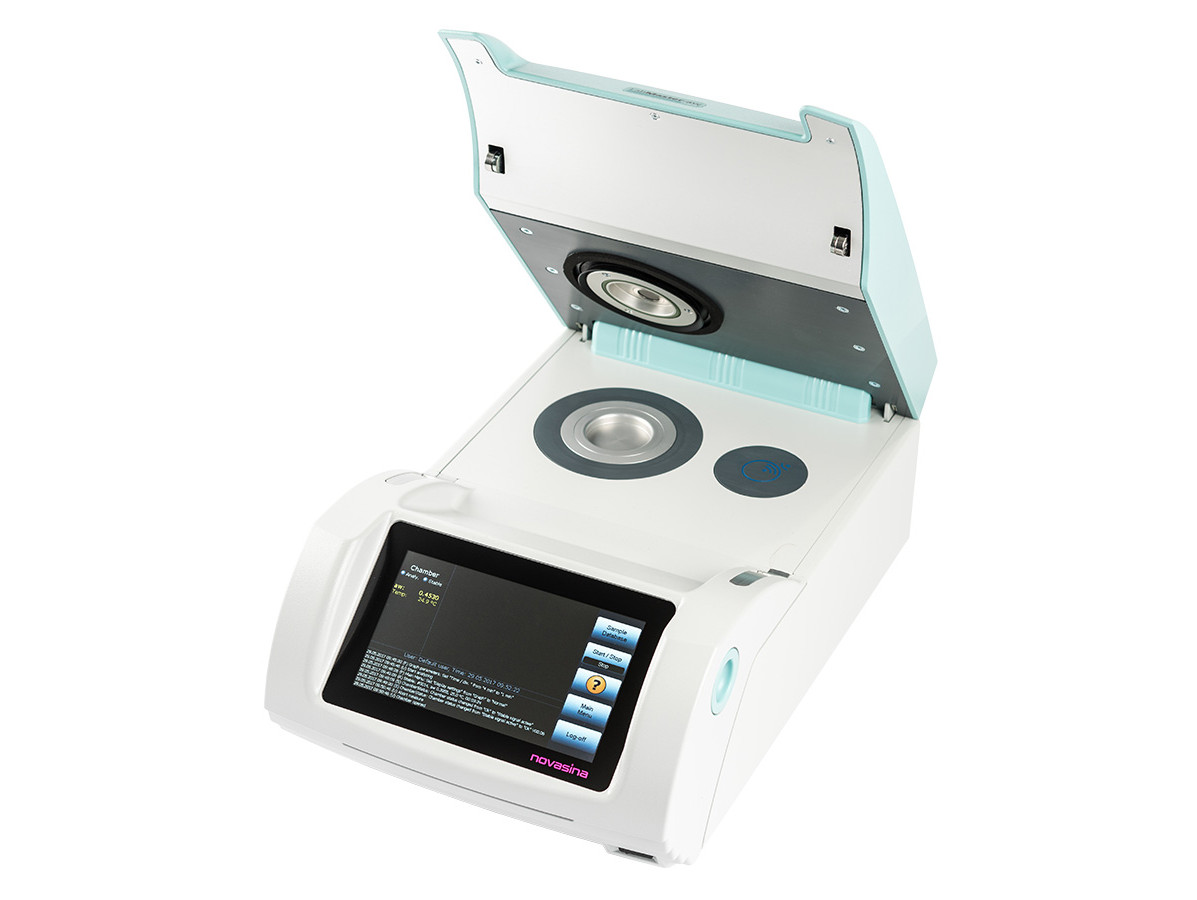

Aw is a measurement of the amount of 'free water' in the product. A value of 0 indicates that there is no free water in the product, while pure water has an aw value of 1.000. Measurement is carried out using an advanced hygrometer, consisting of a climate chamber that can be fully sealed. A highly accurate sensor measures the humidity in this chamber after adding the product. To comply with ISO18787 standards, the measurement takes place in a closed room at a constant temperature of 25°C. Both the product and the measuring chamber must maintain a constant temperature. It's crucial that free water from the product reaches equilibrium with the small air space above the product before measurement occurs. Measurement takes place once the product has reached a state of moisture equilibrium, meaning no further moisture is being released or absorbed by the product.

There's no fixed quantity or weight required for the product being measured. If the product is not homogeneous (e.g., processed meats with fat particles) or contains multiple components (e.g., a granola bar), brief blending is advisable. Moreover, the product should be at room temperature before initiating a measurement. Even frozen products should be brought to room temperature; ice does not contain free water.

To indicate the amount of water in a product, the moisture percentage (or content) can also be used. This number represents the total amount of water in a product, combining both free and bound water. However, this percentage doesn't provide insights into the level of free water, making the moisture percentage the wrong parameter for assessing the microbiological safety of your product.

For reference, fresh meat, fresh fish, vegetables, and fruits typically have a moisture content between 78-95% and an aw value ranging from 0.98-0.99. Milk powder has a moisture content of 3% and an aw value of <0.6. Dried fruits like raisins have a moisture content of 17% and an aw value of 0.60.

The aw value of a product is influenced by various factors, including the amount of dissolved substances in free water, the molecular weight of these substances, and the temperature and humidity of the environment where the product is stored. The rate at which the product reaches equilibrium with the environment is not the same for every product, as oils, fats, sugars, acids, and coatings affect the release of water.

Let's take a slice of bread and a piece of cake as an example, both with a water activity of around 0.9 aw. If we leave both products on the countertop for half an hour, the slice of bread becomes dry and no longer appetizing, while the piece of cake remains quite tasty. This also happens in an aw meter! Bread reaches equilibrium faster than cake, thanks to the butter used in making the cake. Fats make it more challenging for free water to be released from the cake.

Each product has its own measurement time to reach equilibrium, so be cautious of measuring too quickly. If measured prematurely, before equilibrium is achieved, it may appear that the safe limit of, for example, aw = 0.92 for Listeria has been reached, while the actual value is higher which makes it risky. In case of doubt, a duplicate measurement can confirm if the initial reading was accurate. A stability-controlled aw meter prevents measuring too quickly by verifying the necessary equilibrium.

The product's temperature in the aw meter's climate chamber should always remain constant during measurements. A temperature difference of two degrees can result in a 0.01 aw value difference. Temperature plays a significant role, especially in products with higher aw values. The air temperature determines how much water it can hold. For higher aw values, the air above the product contains a substantial amount of water. A small temperature change can significantly impact the water quantity and, consequently, the aw value.

There might be situations where you want to measure at a different temperature, for instance, to understand how the aw value behaves at various temperatures during transport and storage, both in summer and winter. To conduct simulations at different temperatures, it's beneficial to have an aw meter with a range of zero to sixty degrees Celsius. This allows you to mimic nearly all practical conditions.

For reproducible and comparable measurements, regular calibration and cleaning are essential. The frequency of these actions depends on the recommendations of the manufacturer of the meter, ranging from daily to once a month in practice. Calibration should occur at a minimum of two points around the working area, using saturated salt solutions as references.

Measuring aw provides important information about the food safety and properties of a product, which gives you a grip on quality and can saves money during and after production. For this, it is important to be able to trust the measurement of an aw meter. Quickly measuring an aw is risky. An aw meter with a stability check (check for equilibrium) is the best solution for this.

Source: Vakblad Voedingsindustrie 2024