Curious about what's happening in the food industry? And which technological innovations will shape the future? Four suppliers to the food processing and manufacturing industry share insights into the smart technical solutions that assist food producers in addressing the significant challenges of our time.

Finding skilled personnel, the energy transition, raw material scarcity, climate issues and rapidly changing consumer preferences... the food industry faces major challenges. This calls for smart solutions.

Four experts guide you through the key trends and developments in the food sector. All specialize in developing, manufacturing, and implementing innovative solutions for the food production process—from machinery and process technology to complete systems. With their extensive experience, they know the industry inside out: Jannes Jansen, director-owner of Jansen Techniek; Marc Fortuin, Managing Director at Handtmann Benelux; Marcel de Folter, Manager Engineering (MT) at FMI ImProvia and Marcel van den Heuvel, Senior Area Sales Manager at GEA.

This spring, they showcase their technical feats live at the Food Tech Event (May 15 and 16, Brabanthallen, 's-Hertogenbosch). This event unites numerous relevant innovations specifically focused on the food industry under one roof.

Photo: © Jansen Techniek

"Due to the shortage of specialized personnel in production, we face increasingly technological, expertise-related questions," Fortuin begins. "Therefore, we've invested in individuals who, in addition to technical knowledge of machinery, also possess technological knowledge of the products our customers make. In the past, we were mainly machine suppliers, but now it's more and more a collaboration between humans, machines, and products."

Jansen agrees: "Preserving the craft of food production is crucial, and technology enables that! We can ensure that heavy, repetitive work is carried out by machines and robots. People may fear losing their jobs due to automation. I prefer to look at it differently: by investing in technology, you keep your staff on their feet longer. Skilled specialists can continue practicing their profession, achieving higher efficiency. This way, we can continue creating quality products together."

"The well-being of operators is gaining more priority," notes Van den Heuvel. "This includes creating a healthy work environment. Hence, we've innovated the CrumbMaster, among other things. Dust that used to escape the machine is now contained. Less dust in the surroundings means less cleaning of the production space and prevents cross-contamination. Finding skilled personnel is also challenging. Easy operation is therefore a basic requirement. This can be achieved with user-friendly HMIs (Human Machine Interface, red.) that operate like a smartphone; you can swipe, play instructional videos, provide cleaning and operating instructions in the desired language, set operator access to specific actions, track who does what, and more."

Flexibility and cost reduction also play a significant role, adds De Folter: "There's a desire to run many different products through the same production line. That's why our handling systems are modular and expandable. This allows us to grow with the customer."

Fortuin adds: "The latest Handtmann VF800 series is scalable in capacity. Therefore, as production capacity increases, the customer doesn't need to purchase a new machine but can scale up the existing one. In addition, food producers are also looking increasingly for more economical machines; the Fessman smoking and cooking cabinets have therefore been given a higher insulation value to reduce heat loss. With raw materials becoming scarcer, reducing all waste is crucial; customers want a ten-year-old production line to last another ten years, maintaining quality, of course. We increasingly deliver re-engineered machines completely refurbished by the factory."

Jansen chimes in: "Exactly. It's not uncommon for us to install a new module in an older machine. We call it retrofitting. Like the new module to reduce water usage. With our water-saving system for scale removal for various types of fish, one goes from 50 liters to approximately 20 liters per minute. A significant saving."

Photo: © Handtmann Benelux

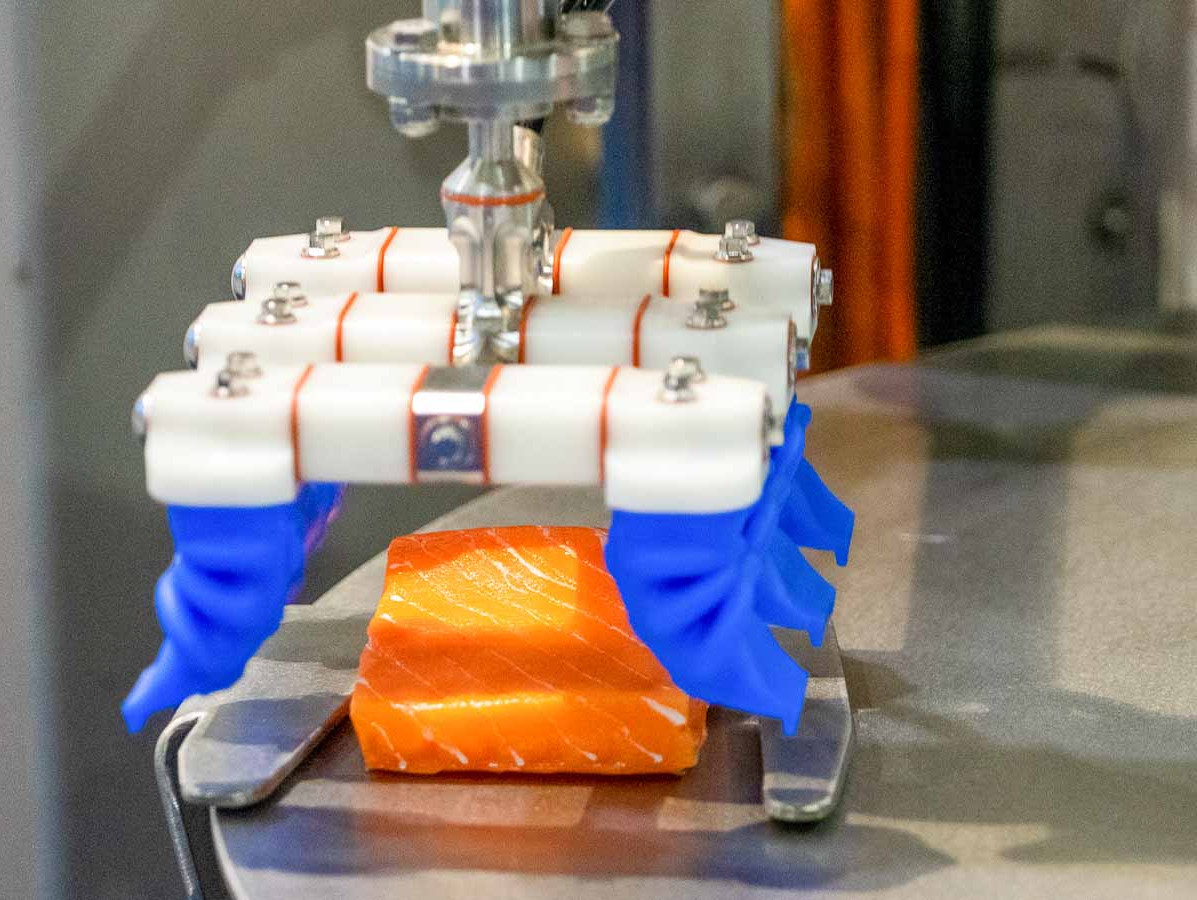

De Folter: "Our expertise lies particularly in gripper technology. We can pick up a schnitzel with a super crunchy coating of cornflakes, but also chocolate, deli meats, vegetables, and fruit. At the Food Tech Event, we will showcase a Bowl-feeder test model. That can sort and place six to seven hundred sweets per minute from a dispensed and portioned bulk, with four sensors to measure the security level."

Jansen: "Two years ago, we introduced our first Robotic Operator, or R-OP. It will be happily doing its thing in our booth. It's the only stainless steel stand-alone self-functioning robot in the world; fully washable, IP 69, with a very small footprint. Essentially, you can remove the production worker from the production line and place R-OP there, with safety shielding. The robot is stable, doesn't get tired, is precise, and reliable. Ideal for mundane repetitive tasks. R-OP is equipped with standard vision cameras, but the software, grippers, and applications are customized for each customer."

"We focus on fully integrated line automation that can be monitored remotely," Fortuin adds. "Machines are evolving into partners that actively contribute and think along. Operators receive crucial information via an app or the machine's control system: when the program is finished, when there's a power outage, or it's time for preventive maintenance. We can also log in to the machines ourselves, although some customers are hesitant to allow external monitoring of their machines."

"Most people fortunately see the benefits of it," Jansen responds. "Especially when they realize it leads to quicker resolution during a breakdown."

"Remote control is gradually becoming the standard," says Van den Heuvel. "Additionally, the food industry increasingly relies on data-driven decision-making. To measure is to know; collecting data provides insight. It enables targeted maintenance and contributes to process efficiency. During the MaxiDrum cleaning process, for example, it's now possible to continuously measure the resistance in the drum. This leads to a significant reduction in water usage because the cleaning takes exactly as long as needed until it's clean. Never too short and certainly not unnecessarily long. The new ProFry also features an electrolytically polished frame on the heat exchanger, reducing polymer adhesion. This results in a 25 to 30 percent reduction in cleaning time during CIPing."

Photo: © Jansen Techniek

"Being able to innovate and helping customers get ahead!" says De Folter. The others nod in agreement: this energizes all four of them.

"We recently tested a module for Mars," continues De Folter. "They wanted a flexible stick packer for a type of fruit candy, with higher reliability. Less downtime, in other words. We succeeded! What's innovative is that the machine can be adapted to strips of 4 to 20 candies without changing parts, at a speed of 300 strips per minute. These are exciting projects. An enthusiastic customer is the icing on the cake."

Jansen also finds happiness in being able to collaborate with the customer: "Especially when they have hit a wall," he says. "To sit down together, start drawing, and propose solutions for a tailor-made machine that can increase their production or reduce costs. In short, a solution that allows them to keep going or even expand; that makes me happy."

Van den Heuvel adds: "Within GEA, we work internally with Product Teams. Multiple disciplines are represented, from 'Product owners,' technologists, and R&D to Service and Maintenance and Sales. Collaborating from different perspectives speeds up the innovation process from initial sketches to execution. It leads to more ownership and better solutions for the customer. I find these interactions incredibly enjoyable."

Fortuin concludes: "We are an international company and do business with clients worldwide. We've noticed that the industry in the Benelux is highly innovative and forward-thinking. Many trends originate in the Netherlands, and I'm proud of that. It makes our work challenging."

Practical Information

Food Tech Event 2024

Target Audience: The Food Tech Event targets directors, management, and technical professionals working for companies active in and for food processing and manufacturing companies.

Dates: May 15 and 16

Time: 10:00 AM – 5:00 PM

Location: Brabanthallen ’s-Hertogenbosch

Website: www.food-tech-event.nl

Main photo: © GEA

Source: Vakblad Voedingsindustrie 2024