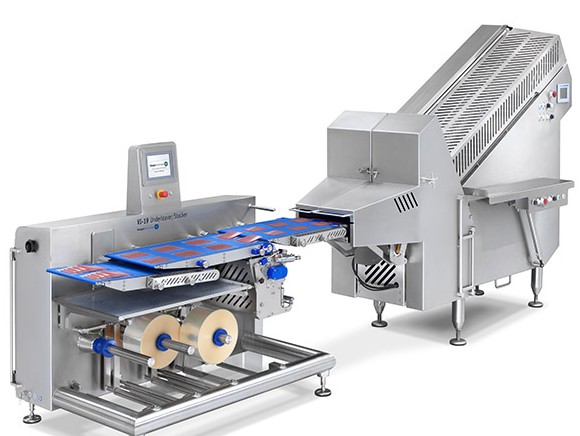

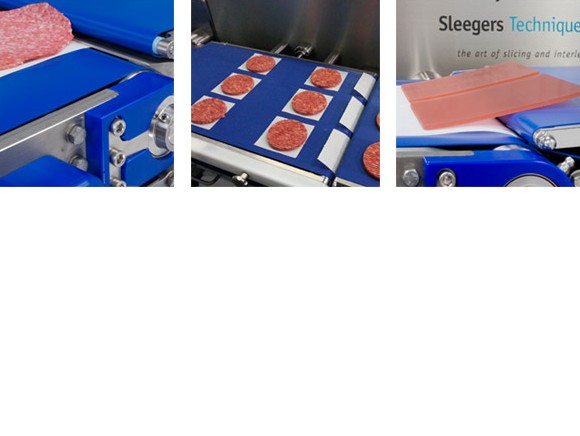

Sleegers Technique BV is the leading specialist when it comes to placing sheets of paper or film under or between sliced products. The process of inserting a sheet of paper or film between slices of cheese or meat immediately after slicing is called ‘interleaving’. This prevents the products from sticking together.

“When adding an interleaver, we always install it directly in the slicer,” explains managing director Huub Sleegers. “This solid combination is not only the most efficient option but also the fastest one. It enables us to slice and interleave up to 400 units per minute. That’s a very high speed with a very low error rate.”

That’s an impressive accomplishment, especially considering the extreme precision involved in interleaving. Huub Sleegers: “You have to factor in the dimensions and the weight of both the product and the film. And the film has to be positioned accurately so that it is placed on precisely the right part of the meat or cheese. Interleaving is a very specific step in the process and relies on various techniques.”

Many companies have a slicer but no interleaver as yet. Thanks to Sleegers Technique BV, their existing machines can be upgraded. “We always discuss the options with the customer beforehand to clarify their wants and needs. But in many cases we can add an interleaver. That’s much more cost-effective than installing a completely new machine.”

Source: © Sleegers Technique