Sleegers Techique BV revolves around the combination of high-tech solutions with the utmost attention to professionalism. Over the years, that has resulted in countless machines and production lines that are perfectly aligned with customer requirements. The company is particularly proud of the three projects presented here.

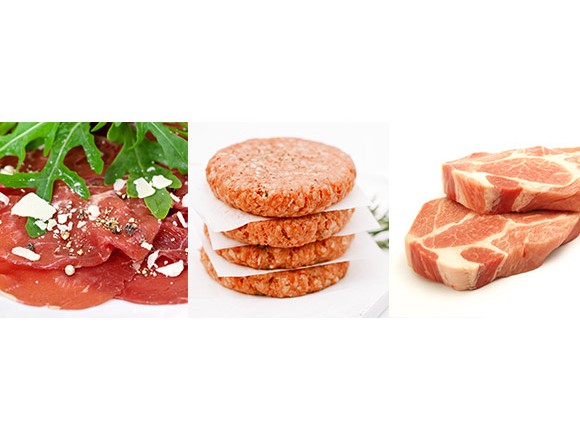

Everyone knows them: marinated rib steaks for the barbecue. In the supermarket you buy them per four or six in a transparent tray. The machine must cut and marinate the slices, after which they can be stacked. This stacking can be done on top of each other or tile by tile. Then the meat has to be de-nested, i.e. put on a tray, and packed. This remains a special project for Huub Sleegers, because it is the very first machine (the VI-01) that he has built all by himself for a supermarket chain.

When Huub Sleegers launched his own brand, the carpaccio line was the first machine designed under it. It was no easy project, because not only is carpaccio presented interleaved with film, but the tender meat is also attractively arranged in an overlapping circle rather than stacked. Sleegers Technique BV developed a unique production line to achieve this. Anybody buying carpaccio from a supermarket today can bet their bottom dollar that the meat was sliced and wrapped by a machine built in the Dutch town of Nieuwkuijk.

Lidl is keen to gain a foothold in North America. To help the retailer do so, Sleegers Technique BV designed a hamburger line stretching an impressive 40 metres. Everything was built at the client’s request. From forming the patties to underleaving, stacking and wrapping, this hamburger line takes care of the entire process. And because they’re mad about hamburgers in the USA, a total of four lines have been installed alongside one another. The next step is to boost the production speed. In the future, it may be possible to produce 400 hamburgers per minute.

Source: © Sleegers Technique