At Dutch Food Industry, we observed one day of the ‘Hygienic Design Training’ by Commercial Food Sanitation, an Intralox company. An international group of food industry professionals went back to school for three days, but above all stepped out of their comfort zone for a while during three intensive workshops.

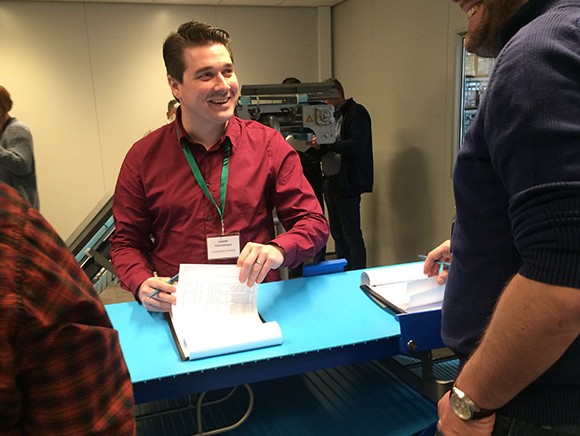

With engineers, food sanitation managers, general managers, plant managers and project managers from countries including Denmark, Belgium, Turkey, the USA and France, it is a cosmopolitan assortment of participants. Claudia Baenen, Business Development Analyst at Commercial Food Sanitation, is their first point of contact. She and her colleagues visit all kinds of food-industry companies every week. Based on the knowledge and experience they amass, they teach the course participants how to apply hygienic design principles in practice. She uses interesting examples to illustrate the impact of hygienic design on food safety. The attendees gain an overview of which materials are available and whether they are suitable or unsuitable. One key aspect is to develop strategies for making a business case for hygienic design projects.

The group is split into three teams of max. 8 people. In rotation, each team attends the three workshops that take place in between the classroom sessions. Over the next three days they will receive a huge amount of new information. In the Equipment Design workshop, the group is assessing a machine design aided by a Design Checklist: “There are lots of sets of guidelines. Our advice is: select just one to work with. Don’t stick to it religiously, but use it instead to identify risks. That information enables you to manage the risks or – if necessary and possible – eliminate them through a redesign.”

In the ‘Design-it-yourself Facility’ workshop the team can get really hands-on, building a model of a factory on a large table. Everyone in the team is given a role: there’s a plant manager, head of engineering, project manager, and safety, maintenance, sanitation and quality manager. They are all fulfilling the role of someone that they don’t encounter in their day-to-day working life. Wearing a different ‘hat’ requires them to look at things from a different perspective and ensure that the construction takes account of zoning for raw materials, semi-finished products and ready-to-eat products, of underpressure and overpressure, of points for water supply and drains, and how many will be needed. How will people, products and waste move around within the facility? Where are goods received into and dispatched from the factory, how can all the areas be cleaned without cross-contamination, where is waste generated and how can it be disposed of safely?

The ‘Hygienic Principles of Infrastructure Design’ workshop also presents a practical assignment; the team must convert an existing space into one that is suitable for food production. This time, the team is primarily focused on the materials and the available budget. They have to make quick decisions: Which type of floor and why? Which drains are available, and which are the most suitable? Which type of wall should be placed where, and how should we attach the necessary items to the wall?

“Above all, we try to show lots of good examples and to give the participants concrete ideas that they can use in their own companies,” explains Claudia. “The attendees find out for themselves that it’s virtually impossible to achieve ‘perfect hygienic design on all sides’ and that it’s therefore essential to know where potential risks are. Only then can you adequately manage those risks.” “Hygienic design is about reducing the risk,” is how one of the workshop leaders succinctly puts it.

There is fervent discussion, consultation and knowledge sharing within the teams. For some participants, it makes their head spin – there are so many aspects to consider. And yet there is plenty of humour too, and as the training course progresses the teams settle into the flow of things. The relaxed atmosphere fosters open communication, and one thing is extremely clear: it’s OK to make ‘mistakes’. Claudia: “The group process and the ensuing discussion are more important than the ‘right’ or ‘wrong’ outcome. It’s about the participants becoming aware of possible threats to food safety and about them experiencing how to collaborate effectively in multidisciplinary teams to achieve a common goal and optimal results.”

One of the participants was Jan Torfs, General Manager at Leon Torfs Engineering & Machineconstructie from Belgium (www.torfs-leon.be). He looks back on the experience with a sense of satisfaction. “A common thread running through the whole course was ‘What you can’t see, you can’t clean’. That helps you to look at your own designs differently. For me, the main takeaway was that we can make a lot of improvements through small adjustments. What made the biggest impression on me? The fact that so many food processing companies still don’t have things organised properly, such as zoning – especially in the case of companies that make ready-to-eat products. And that some architects design food manufacturing facilities without knowing anything about hygienic design principles. Hygienic design really does require a different mindset and a different way of working. There’s always room for improvement, providing you’re open-minded and want to be innovative.”

Source: © Vakblad Voedingsindustrie 2017