Current chemical and thermal processes used to ensure the hygiene and safety of products have their disadvantages. Cold plasma can be a mild alternative in controlling micro-organisms, microbial spores and viruses. What does this technology entail and what can the food industry do with it?

In recent years, there have been many scientific publications of studies on the applications of non-thermal plasma technology (cold plasma) in the food industry. Indeed, researchers have discovered that plasmas operating at atmospheric conditions have an inactivating effect on a wide range of micro-organisms; including disease- and spoilage-causing bacteria and fungi, as well as microbial spores and viruses. This effect takes place at a relatively low gas temperature. It requires standard operating gases (compressed air, oxygen, nitrogen), water and energy, and no thermal degradation effects occur on the product. Moreover, it is a dry and residue-free process. Despite these advantages, plasma technology is not yet used in the food industry. Why not?

In part, this is due to a lack of equipment that can operate on food applications at relevant scales and in a flexible manner. Moreover, there is still too little knowledge about (1) the relationship between chemical composition and effectiveness on the micro-organism; and (2) the effects of plasma treatment on the quality, nutritional parameters and safety of food products. In addition, applying plasma technology to food products is not yet legally authorised. A prerequisite for authorisation is that safety is sufficiently substantiated for the intended application. Therefore, many research groups are working on plasma technology accumulating detailed knowledge that is needed to create a dossier; and thus to ensure future implementation in the food industry. One such research project is the Dutch Plasma4Hygiene project, which will end in early 2023.

The Plasma4Hygiene project is a multidisciplinary collaboration between researchers from TU/e-EES (with knowledge of electrical systems and plasma chemistry) and researchers from Wageningen Food & Biobased Research (with knowledge on the product and process side and food microbiology). The consortium also includes companies from both the high-tech and food sectors. The project was funded by the Top Sectors AgriFood (project code AF17202) and HighTech systems and the companies in the consortium. Within the project, a number of plasma product combinations have been examined. The aim of the research is to gain more insight into the possibilities and limitations of this technology for the food sector.

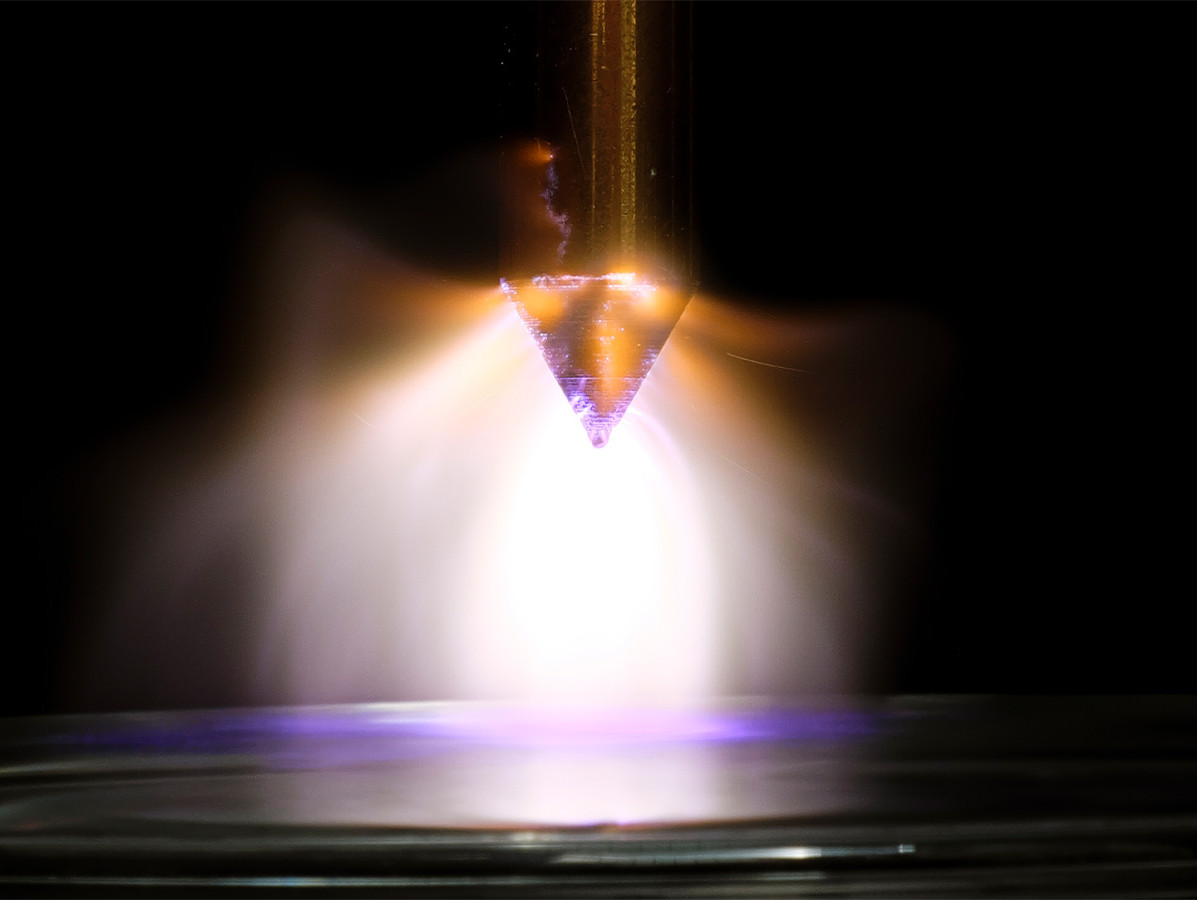

At TU/e, a non-thermal, low-power plasma jet that generates atmospheric air plasma was developed within this project. Experiments on products at Wageningen Food & Biobased Research were carried out with this plasma source. In addition, work was done in Eindhoven to develop/improve emission spectroscopy as plasma diagnostics. This allows the composition, and thus the activity of the plasma, to be mapped. This is important for monitoring, controlling and directing plasma processes in future industrial-scale applications.

Other (already authorised) applications

Cold plasma technology is now mainly used in the semiconductor industry for the production of wafers. There is also a strong development to use the technology for flue gas cleaning, breaking down volatile organic compounds and odour; for surface modification of plastics and non-woven materials; and in biomedical applications (disinfection and healing of wounds, dental care and cancer treatment).

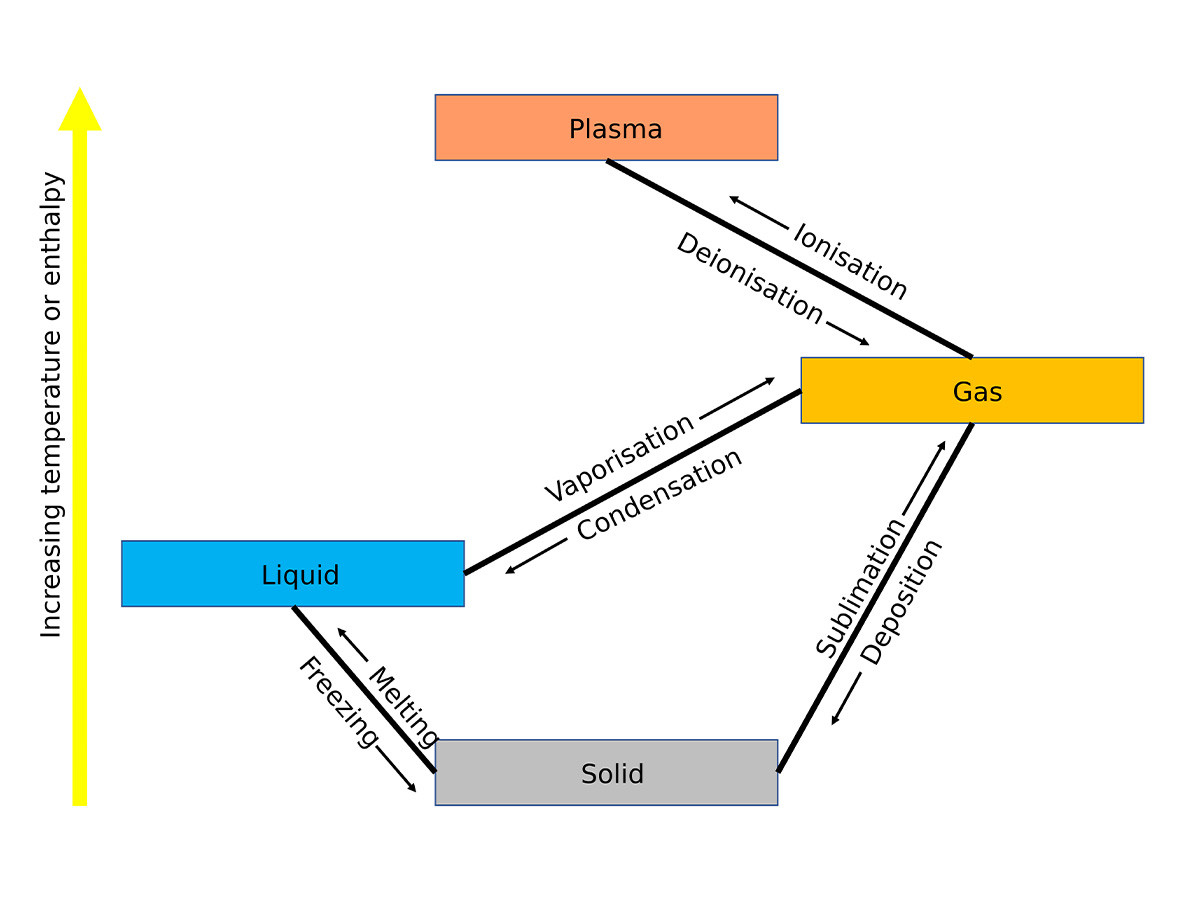

Figure 1.

We know three manifestations of matter in everyday life: solid, liquid and gas. But there is a fourth state: plasma (Figure 1). It consists of a mixture of photons, neutral, reactive and charged particles that display collective behaviour. Plasma is actually electrically charged (ionised) gas. The transition from a gas to a plasma occurs gradually, with increasing thermal energy.

A plasma is created by coupling electrical energy into a gas via energetic electrons. Through effective collisions, the gas particles (atoms and molecules) temporarily gain a higher energy level and also lose electrons, creating a highly reactive gaseous medium consisting of energetic molecules and atoms, radicals, ions and UV radiation. Atmospheric plasmas in air produce reactive oxygen (e.g. hydroxyl radicals and ozone) as well as reactive nitrogen (nitrogen oxides, nitrogen oxy acids), which, among other things, lead to inactivation of (pathogenic) micro-organisms, meaning disinfection. Bombardment of energetic ions (electroporation) and incorporation of UV photons also contribute to this.

In cold plasma technology, the temperature of the heavy gas particles (the neutral particles and ions) remains very low, allowing reactive particles to be produced energetically efficiently. In the process, the temperature of the treated surface remains low. Although scientific research uses a wide range of gases to generate plasma, for food industry applications, only air and nitrogen are economically feasible.

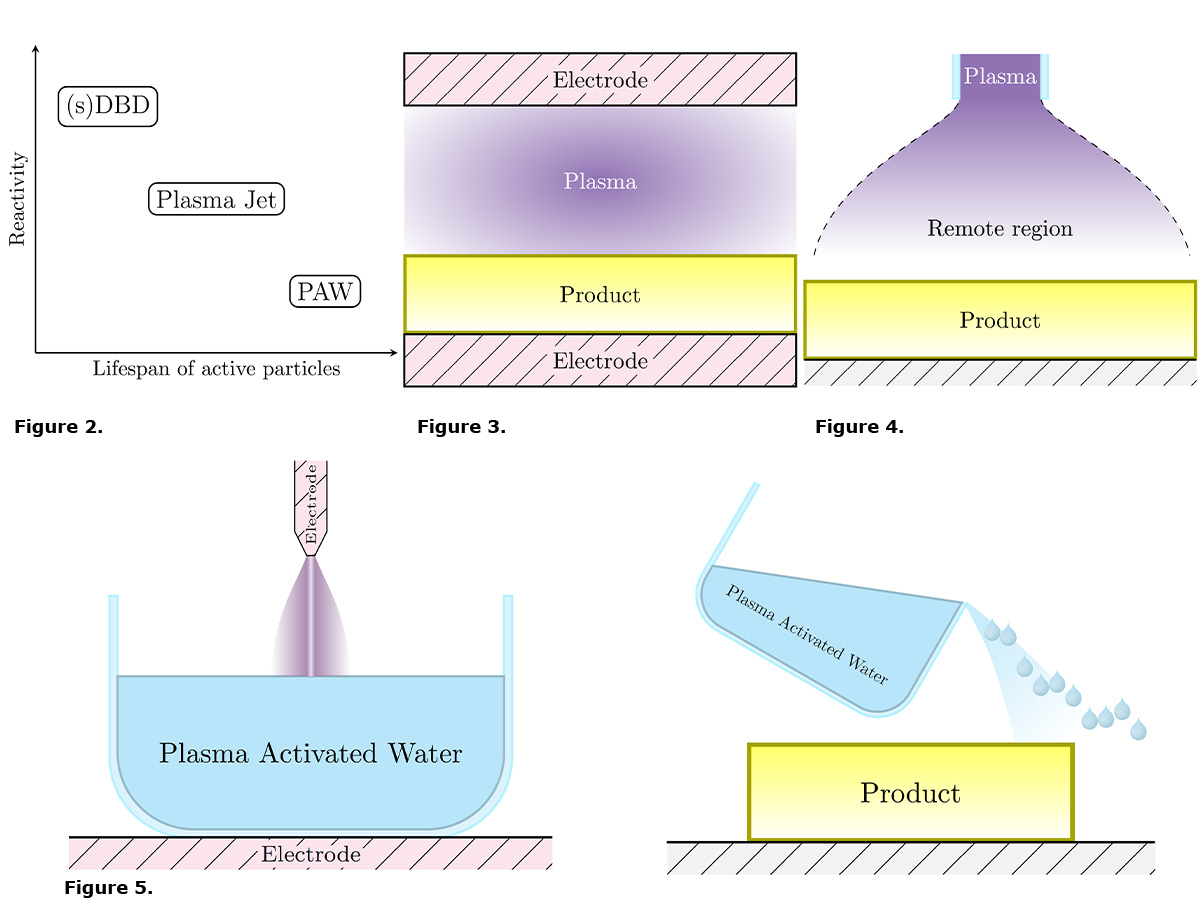

Plasma technologies have been classified in different ways in this project (Figure 2):

In direct plasma treatments, the plasma is in direct contact with the surface. An example is surface Dielectric Barrier Discharge Plasma (sDBD) (Figure 3). In the plasma, highly-reactive, short-lived oxygen and nitrogen species dominate. Because the lifetime of the reactive species is short, this application is especially suitable for smooth, regular surfaces where a short distance between source and the surface that has to be treated is possible. One possible application for sDBD is disinfection of surfaces of processing, transport and storage systems that come into contact with food.

In remote treatment, the plasma generation and the surface that is to be treated are physically separated. An example is the plasma-jet setup (Figure 4), where the plasma effluent is directed at the product at a relatively short distance. The food substrate now receives only energetic, short-living species (metastables). This shows that plasma technology could be interesting for application to cheese. This is being investigated further.

In indirect treatment, water can act as an intermediate step. It is activated with thermal discharges; after activation also called Plasma Activated Water (PAW) (Figure 5). The antimicrobial effect of PAW, if kept refrigerated and dark, can be maintained for quite a long time (up to several days). Because PAW is acidic, applications are limited to products that can tolerate it.

Depending on how and when the plasma and product interact, all three methods can be potentially effective.

Figure 2: Operating field of the types of plasmas in this study. Figure 3: Schematic representation of a direct plasma technique - sDBD. Figure 4: Schematic representation of a remote plasma technique - Plasma jet. Figure 5: Schematic representation of an indirect plasma technique - PAW.

The project tested with both gas plasma (nitrogen or air) and PAW for various food-related micro-organisms. The study showed that spores of Penicillium discolor (a spoilage mould that can be isolated from cheese) were highly sensitive to treatment with nitrogen or air-gas plasma on a model surface, but not to PAW. The air plasma jet developed by TUe was also found to be effective on the cheese matrix inoculated fungal spores; they were inactivated there. This shows that plasma technology can be interesting for application on cheese. This will be investigated further.

The complexity of the food matrix may be a bottleneck for a number of applications. For instance, promising results obtained on a model surface in the lab were not always translatable to a real product. This happened with chicken products (chicken leg and chicken meat), for example. To better understand the effect of the matrix on plasma treatment, Wageningen Food & Biobased Research developed a miniature chicken matrix for this project, allowing the researchers to vary the composition (ratio of meat protein and fatty chicken skin), but without the complexity of the 3D structure (folds and pores) in which bacteria can hide.

For the Escherichia coli bacterium, which is a model for faecal contamination, the base matrix (without the addition of chicken protein and chicken skin) inactivated more than 4 log units (factor 10,000) with atmospheric air plasma within 15 seconds. When chicken protein or fat-rich chicken skin was also added to the matrix as an ingredient, the reduction was barely 1 log. One explanation could be that the reactive species from the plasma here are scavenged by the fat and proteins. This means that products with a high protein or fat content are likely to be less suitable for treatment with this type of plasma.

The project also investigated the effect of PAW on Listeria monocytogenes on fresh products, such as mushrooms, which involve a washing step. The Listeria bacteria were found to be very sensitive to PAW itself. On mushroom, 1 log reduction could be demonstrated. However, an increase in nitrite derived from the PAW was also measured after treatment of the mushroom. Nitrite uptake was also measured in other products with an open structure or cut surface, such as sliced endive and scraped carrots. For cherry tomatoes, where the skin forms a water barrier, no increase in nitrite was measured. The uptake of nitrite thus limits the application of PAW to products with a water barrier. There is room for improvement here in the future. Nitrite formation can after all be controlled with energy density and gas composition.

Cold plasma offers opportunities to improve the microbiological shelf life and safety of products. Whether this makes plasma technology interesting for the food industry remains to be seen. It is important to map out the effects on the product per application and optimise the process.

Of course, the cost aspect also plays a role. The operational costs of plasma technology depend on the technique used, the design and the application. Experiments with an industrial test set-up will have to determine the plasma energy density required to achieve the desired reduction of pathogens and/or spoilage-causing micro-organisms. Based on this, the applicable prices for electricity, water, compressed air and nitrogen can be used to estimate operational costs.

No industrial equipment is available yet, but electrical systems for plasma generating are scalable in theory. Depending on the product to be treated, dimensions and transport rate, the required power can be obtained by coupling modular basic power supplies. This allows scaling up to high volumes, which is interesting for industry.

An additional advantage is the intelligence of these electrical systems. Depending on the line speed of the product, plasma power can be controlled in such a way that the desired energy per area remains constant. If transport stagnation occurs, plasma power is switched off to prevent product damage and save energy.

Sustainable innovation in healthy food, fresh food chains and biobased products through applied research. That is what Wageningen Food & Biobased Research, part of Wageningen University & Research, stands for. The research institute has a lot of expertise on the cutting edge of food safety, product quality, logistics chains and food legislation.

www.wur.nl

Within the Electrical Engineering Faculty of Eindhoven University of Technology, the Electrical Engineering Systems capacity group carries out fundamental and applied research in the fields of electrical components and diagnostics, power quality, electromagnetic compatibility, power electronics of power grids, digital power and energy systems, smart grids and network planning, optimisation and electricity markets, pulsed power technology and electrical gas discharges.

www.tue.nl

About the authors

Dr.ir. Masja Nierop Groot is Expertise Leader Applied Food Microbiology at Wageningen Food & Biobased Research.

Dr.ir. Wilfred F.L.M. Hoeben is Assistant Professor of Chemistry & Physical Chemistry of Plasmas, Eindhoven University of Technology, Department of Electrical Engineering, Electrical Engineering Systems group.

Marco C. de Peuter is PhD candidate in plasma technology for applications in agriculture, Eindhoven University of Technology, Department of Electrical Engineering, Electrical Engineering Systems group.

Source: Vakblad Voedingsindustrie 2022