It seems almost too good to be true: an optimal and hygienic cleaning method using less water. But, thanks to Undine® by Innovative Water Concepts (IWC), it really is possible.

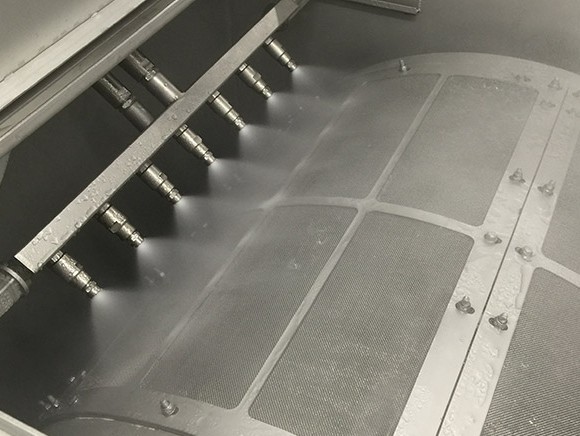

The technique is based on a simple principle, as inventor and technical manager Ton Winters explains: “Air and water are mixed in a small mixing chamber measuring just a couple of centimetres. The result is a spray of very fine droplets which is sprayed onto the dirt at high speed. This even makes light work of residues such as blood, egg white and juices. Furthermore, we’ve designed the technology in such a way that it reaches into every nook and cranny to achieve an optimal cleaning result. After all, you can’t clean the areas that you can’t reach.” The air pressure and water pressure can be adjusted as required, making Undine suitable for use with fruit and vegetables as well as with meat and conveyors with caked on dirt. Ton: “We use multiple mixing chambers for an even more powerful result. As you can imagine, tackling stubborn dirt requires more energy than the light cleaning of fruit and vegetables. Thanks to the air and water mixture, the fine spray doesn’t damage the surface which makes it ideal for more delicate products.”

Ton first discovered the concept behind Undine over 20 years ago, back when he was a vegetable processor. A broken compressor sprayed mist onto some bearings and they were impressively clean afterwards. In 2004 he decided to commercialise the technique, which by time it had been named after a German water nymph. In partnership with Tjerk Nijdam he founded the company Innovative Water Concepts (IWC). Around 250 companies at home and abroad are currently using Undine. Tjerk: “When a company enlists our help, we first visit the facility to take stock of the situation.

Benefits of Undine:

- Savings of up to 90% on water and energy

- Significantly better cleaning result

- Savings of up to 60% on labour costs

- Faster and automated cleaning

- Less loss of production time and product

- No blocked nozzles

Because Undine is generally made to measure, we determine the best positioning and configuration for the mixing chambers and nozzles. We produce everything here in the Netherlands, meaning that we have short lead times. And we supply everything to our customers as plug & play so that they can install the system themselves. Undine is easy to integrate into an existing machine or production line. In the case of complex projects we can of course also offer customised installation work.”

Nowadays, the IWC employees travel to all four corners of the world to help companies based on this revolutionary technique. “Above all, we work with a lot of poultry slaughterhouses because they require thorough cleaning after each sub-process. That uses huge volumes of water and we can help them to make substantial savings,” says Tjerk. “But we also work for pork and beef processing facilities, fruit and vegetable producers and machine builders.” Ton: “Undine can be applied in countless different ways, but we’ve specifically chosen to focus on the food industry. That’s our background and where our experience lies.”

Erik Zaayer, operational manager at poultry processing company 2 Sisters Storteboom, can speak from experience. “18 months ago we were looking for ways to significantly reduce our water consumption. We set up a meeting with Ton and he advised us to design overcapacity into our system by installing more nozzles than strictly necessary. The chickens generally arrive with us with empty stomachs, but if that’s not the case then I can now take quick action and solve the problem by switching on the extra nozzles – so that was good advice. Things like that underline that IWC truly understands the production process.” Besides improved hygiene and reduced water consumption, Erik has noticed an added advantage: “Because we now have better control over the cleaning process, fewer visual checks are necessary. That’s enabled me to make considerable savings in terms of man-hours. Undine was a sizeable investment but it has already more than paid for itself.”

When it comes to the quantifiable benefits of Undine, the figures speak for themselves: companies can save up to 60% on labour costs and up to 90% in terms of water and energy consumption. They can speed up and automate their cleaning which reduces the amount of changeover time and leads to less loss of both production time and product. “This really is the best cleaning method around right now,” comments Tjerk. Ton adds: “Furthermore, when used with meat the Undine technique covers it in a kind of film. This enables you to minimise the moisture losses during refrigeration so you’re left with more meat in the end – and hence more turnover.” Retaining more end product is an aspect that engineer Henk de Weert also likes about the use of Undine at Lamb Weston/Meijer (manufacturer of potato products). “Our French fries are optically sorted for defects on a conveyor, based on light. If starch residues remain on the conveyor, they disrupt the sorting process. Thanks to Undine we can clean each conveyor quickly and thoroughly. That’s good for the sorting process, meaning that we can now get more fries out of each potato. So I’d definitely recommend Undine – there’s no doubt about that!”

Source: © IWC International