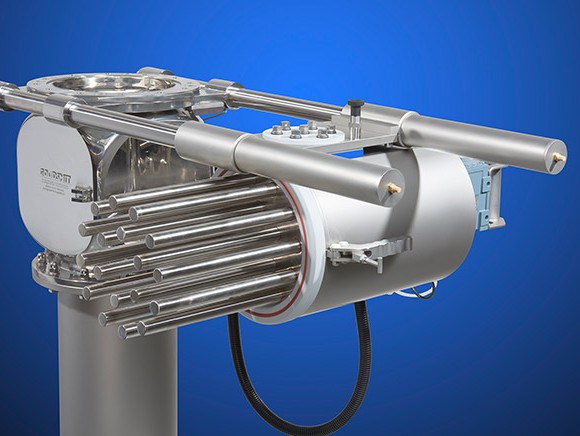

PureFinish is a post-processing technique developed by Rösler. This technique allows Stainless Steel to be finished to a smoother surface with a low and reproducible SRI value below 0.010. In practice, this produces a surface with a low degree of adhesion for contaminants, perfect for effective cleanability. The process offers excellent opportunities within the industries where the demand for hygiene is very high, particularly within the pharmaceutical and food industries.

Within the food and pharmaceutical industries hygiene is a top priority. Not only for safety, but also to prevent contamination and to ensure the quality of a product in terms of its taste, aroma and appearance. The occurrence of contamination through bacteria, proteins or other elements must therefore be prevented. In addition to an optimal design of transport and process, plants require a defined, homogeneous and reproducible surface for all parts that come in direct contact with the customer’s products. At this point Rösler’s PureFinish process offers interesting perspectives.

PureFinish is an environment-friendly wet blasting process where media suspended in water is blasted on a surface with force. Important parameters during the blasting process includes, blasting pressure, type of material and the particle shape and size. After 40 years of experience in the field of wet blasting and vibratory finishing, Rösler knows how to apply the right process when surface finishing is required.

Besides wet blasting, Rösler also developed a process aimed at polishing smaller components using vibratory finishing techniques. During the vibratory process, grinding or polishing stones (Chips) vibrate to produce a sliding / grinding movement along the products surface which smoothens it. These processes can be distinguished by a high degree of homogeneity and reproducibility.

The PureFinish treatment has been extensively tested by TNO. TNO, a Dutch Organisation is the leading research institute for Applied Scientific Research. The SRI value (Soil Retention Index) was investigated because this parameter most accurately describes the relationship between surface structure, contamination and cleanability.

“A low SRI guarantees a low rate of contamination.”

The Ra value measurement is proven to be limited because it only gives an average value for the roughness which says nothing about fluctuations of peaks and valleys within the surface. The formula for determining the SRI includes the Sa-value (roughness measurement of the surface in 3D), the frequency peak (Pc) and the corrugation (Mr2). The lower the SRI, the less contamination and the lower the shear forces required to clean a surface. The latter is important to guarantee a proper “cleaning-in-process” procedure (CIP).

The SRI measurement from TNO for wet blasting was 0.010 and 0.008 after vibrofinishing. PureFinish for that matter scores equally or significantly better than other companies that also use wet blasting to achieving a high quality standard (SRI 0.020). Convincing figures that underline the potential of the PureFinish process. The Ra value is dependent on the products being processed between 0.30 and 0.55 microns and thus also meets the current requirement of <0.8 of the EHEDG.

Minimum residue

The PureFinish-process developed by Rösler Benelux gives a better surface texture with an SRI much lower than regular dry bead blasting, which inevitably leave media residue in the surface. The PureFinish process allows a water film to form an effective protection layer against hard impact from the abrasive particles (abrasives) on the area being treated. As a result, the amount of residual particles in the material is minimal.

For the PureFinish treatment, Rösler has developed a special process media. The ratio thereof can be monitored and adjusted manually or automatically during the process. The process media can be recycled and fed back to the system to maintain a constant quality with reduced consumption.

The charm of the new process is that its user has a direct view on the process and the end result. The requirements can be accurately aligned through a selection of process parameters. Unlike other processes, PureFinish therefore is an open and transparent process. The supplier of equipment offers both blasting systems and vibratory finishing installations. For both techniques the user has a direct view of the manufacturing process, which was not the case until now. Blasting and vibratory finishing equipment can even be integrated into existing production lines or be automated with robots and / or transport systems.

In the test laboratory Rösler conducts all necessary tests to identify the optimum parameters in preliminary research and development stages. The development includes everything from the design of the blasting and vibratory finishing process media to the process parameters required in relation to the part and the given process conditions. This offers excellent opportunities to determining and control the surface treatment process. The new development means that companies are now able to perform stainless steel surface finishing in-house with an installation according to high industry standards.

Rösler - one of the biggest players in the field of mechanical surface treatment - supplies PureFinish equipment for the process both in blasting systems (wet) as well as vibratory finishing installations. Minimise risks by introducing your equipment and materials to the PureFinish process.

Source: © Rosler