Food producers and processors face significant challenges. The use of smart sensor technology in food processing offers part of the solution. The complexity and high variability of food products and processing are the main hurdles. But where do the opportunities and possibilities lie?

The need to produce food sustainably is immense. Key drivers include the growing global population, increasing industrialization in developing countries, climate change, rising energy prices (and in the future, water as well), and labor shortages. All these factors push for a more sustainable food chain.

Current process control in food processing mostly relies on physical parameters such as temperature, pressure, time, and pH. Product insights are often obtained through laboratory tests on the end product after production has finished. Adjustments to the process are then made based on previous produced batch data. A more efficient approach would be to use real-time data. With the adoption of new sensor systems, it is possible to quickly and in real time gain insight into the composition, structure, microbial status, and presence of unwanted components in raw materials, semi-finished, and final products. In short, process control based on real-time product information offers significant opportunities for the industry.

The goals for applying these technologies are varied. Some sensors can detect fraud, observe internal defects, or identify structural aspects and even specific components. While some of these technologies are already in use, others are being refined or are still in very early stages.

In addition to visible-spectrum camera systems, there is increasing use of technology beyond the visible range. Examples include NIR, FT-IR, and Raman in specific bandwidths, and hyperspectral cameras covering a broad range. Easy-to-use electrochemical detection methods for identifying specific components (such as unwanted reaction products that negatively affect quality) are also in development. Furthermore, complex combinations of various sensors are being worked on to improve accuracy. Here are a few examples:

A glimpse of advanced sensor technologies

- Electrochemical detection: detecting electrical signals via oxidation and reductive reactions.

- Affinity sensors: using specific binding to detect or quantify individual components (e.g., in biosensors).

- Microfluidics: microsystems for transporting, mixing, and separating liquids (lab-on-a-chip).

- UV/VIS, NIR, FT-IR, Raman: interaction between radiation and material to quantify chemical components based on wavelength.

- Hyperspectral imaging: analysis across a wide light spectrum, particularly on surfaces.

- Lens-free imaging: in-line digital imaging for automatic identification and classification of cells, materials, particles, and more.

- Fluorescent spectroscopy: detecting photons released during molecular agitation, such as for detecting aromatic components.

- Acoustic detection, including ultrasound: identifying irregularities through compositional differences.

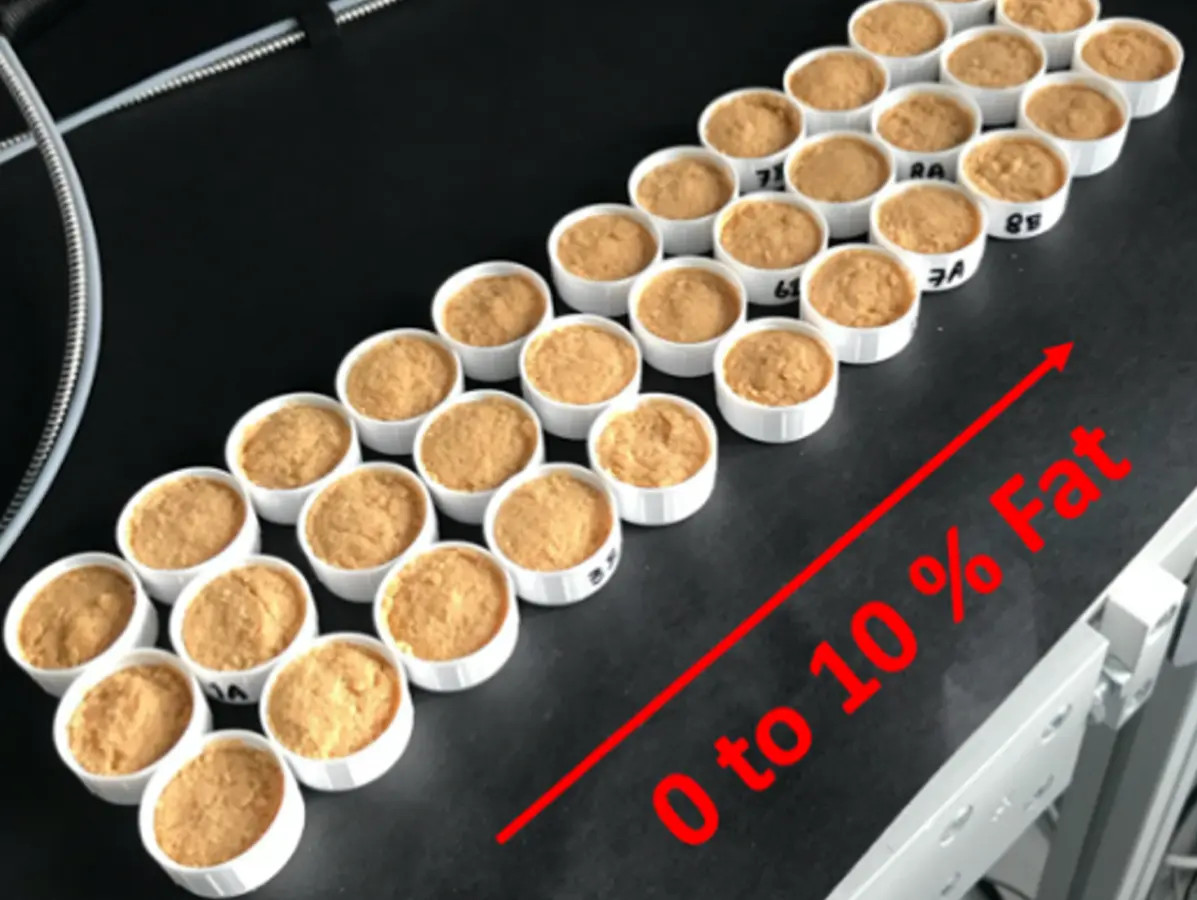

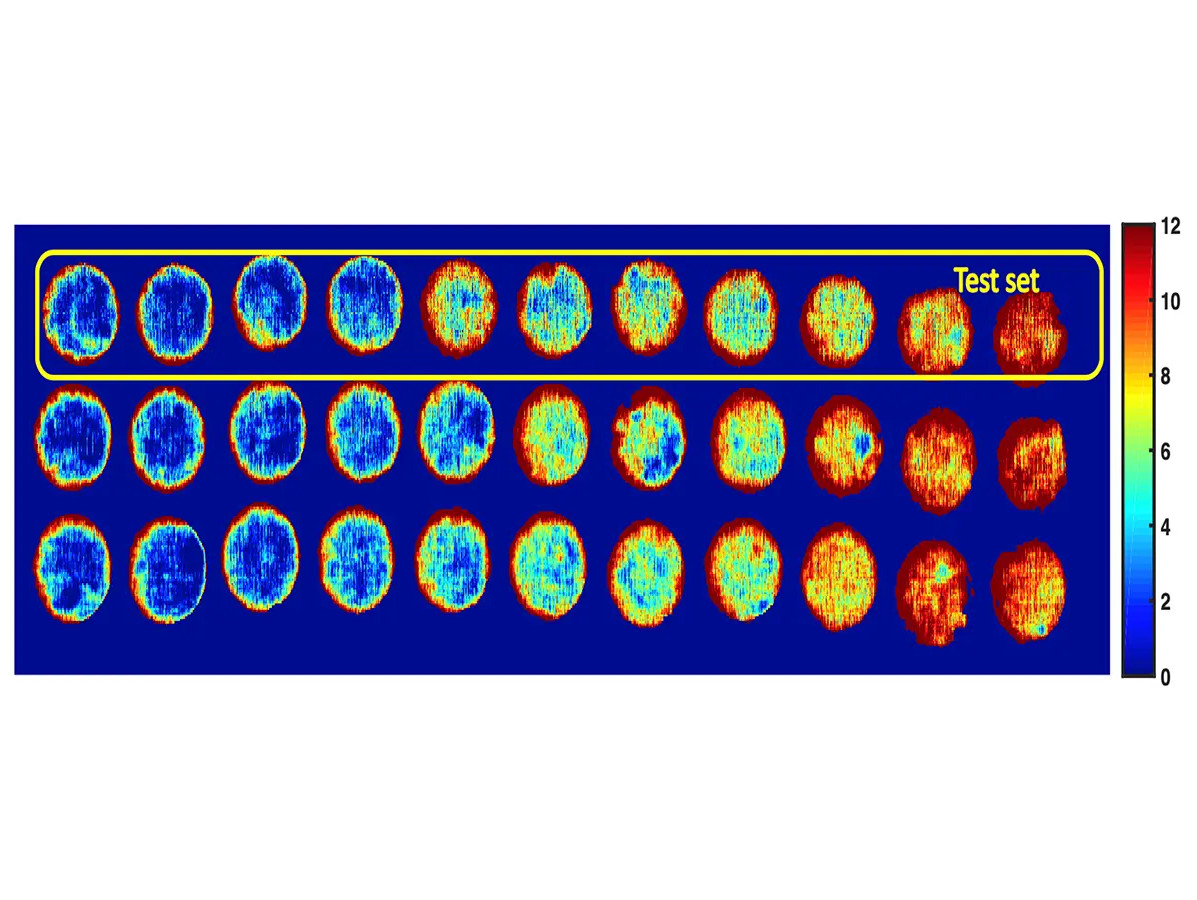

Example of meat substitutes with increasing fat content and matching display based on spectral measurements.

Adopting new sensor technology involves more than just developing reliable sensors. Linking the technology to business strategy is crucial, and collaboration between technology and service providers is essential. The robustness and reliability of these technologies in real-world conditions also matter. At present, proof of effectiveness in practice is lacking for several sensors. This is why Wageningen University & Research (WUR) is heavily involved in field research—both in pilot-scale facilities in Wageningen and in production lines at various companies, in collaboration with the OnePlanet Research Center. OnePlanet, a partnership between imec, WUR, and Radboud University, focuses on developing new technologies in agriculture, food, and health sectors.

Working closely with companies, efforts are underway to further develop and test new sensor technologies. Key areas of focus include ensuring functionality at realistic production speeds, robust data communication, and specific calibration protocols. Research is also being conducted on wireless communication in factory settings, addressing potential interference from building structures and equipment. These developments aim to foster effective adaptation of the technology, ensuring that expected improvements in efficiency and product quality are realized.

Managing and processing data from sensor systems is a critical aspect for successful adoption. This includes secure data storage, data quality, and analysis using advanced techniques, including artificial intelligence. The resulting insights must be integrated into factory control systems to support, or even automate, decision-making on the production line.

Trust in the technology from operators is essential for its acceptance and usage, rather than it being perceived as a threat. Involving multiple disciplines within the company is key to a successful introduction of sensor technology. Everyone needs to understand how the system will be used, whether in R&D or production. Both environments require robust systems that function reliably over time. However, a system designed for a laboratory environment will differ from one intended for production lines, where speed, non-invasiveness, and compatibility with cleaning procedures are critical.

The wide variety of food products and processing technologies calls for tailored solutions. By optimizing the technology for specific products and processes, such as through product-specific calibration, many challenges can be addressed. Fortunately, various sensor technologies can be applied across a broad range of food products. For instance, NIR is well-suited for determining quality attributes in beverages, dairy, meat, coffee, and honey.

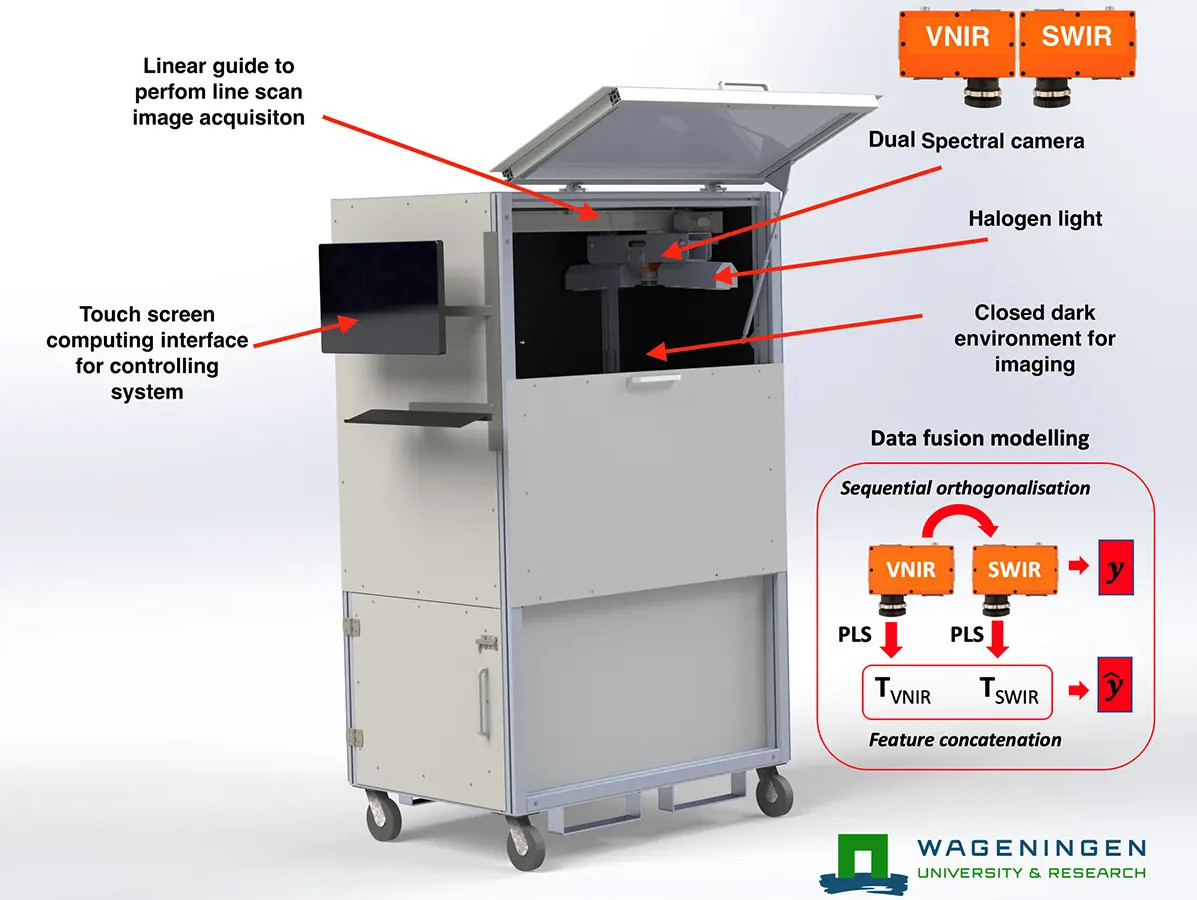

Spectral cabinet with cameras to analyze multiple samples simultaneously in a short period of time.

Wageningen Food & Biobased Research contributes to practical adaptation through applied research under the theme of Smart Food Processing. This goes beyond replacing traditional offline lab analyses with new sensors. In addition to necessary technological developments, factors such as representative sampling also play a role. Especially for products with low tolerance for unwanted components or the presence of microorganisms. Sensor systems, including their data processing, must be optimized for specific products, in terms of both equipment and calibration procedures. Furthermore, it is important to determine how data analysis results can be used to control production lines, and how the system fits within the existing infrastructure, including sensor cleaning and maintenance.

New sensors present many opportunities. They provide insight into product quality and process flexibility, improve the efficient use of raw materials, and help you better anticipate external factors. Investing in sensors and data analysis offers the potential for real-time process control based on the properties of the food itself. Collaboration between researchers, food processors, and equipment and service providers is essential for achieving successful applications.

Photos © Wur

Source: Vakblad Voedingsindustrie 2024