There is a growing need for innovative processing techniques that increase the efficiency of food production, reduce waste and improve food quality. Smart' food processing plays a crucial role in this. What is possible with these techniques? Where are the opportunities? And what obstacles must be overcome?

The growing world population and climate issues are causing an increasing demand for more and sustainably produced food. Finding answers to this major issue is one of the spearheads within Wageningen University & Research (WUR). Researchers and experts throughout WUR are joining forces to develop digital solutions for a more efficient, sustainable and intelligent future for food and agricultural production.

For example, researchers from the fundamental cluster Food Process Engineering and the applied research institute Wageningen Food & Biobased Research are working together to improve the current state of 3D food printing. In a recent study, they investigated whether it is possible to improve the efficiency of the process with the introduction of digital techniques such as computer vision and adaptive control strategies. This research was partially funded by the Mechanical Engineering Sector Plan (NWO).

3D food printing is on the rise. Chefs are already using the technology to produce creative shapes for their guests with mashed potatoes, hummus, chocolate and pasta. Museums have 3D food printers for printing edible souvenirs; Egyptian pyramids, the Great Wall, the Eiffel Tower; anything goes. And food technologists are using 3D food printers to texturize plant-based proteins to create sustainable alternatives with similar texture and flavor to meat. Meanwhile, efforts are underway to introduce 3D printing for the mass consumer market.

As easy and accessible as it may seem to 3D-print food products; the practice is challenging. It takes a lot of time to optimize printing parameters for 3D printing different food compositions and/or designs, and many trial-and-error experiments are required to tune the printer for new or different materials. For example, a recipe for printing chocolate cannot be used one-to-one for printing a cookie dough. In short, producing desired designs requires complex and manual controls. These hinder the widespread use of this technique for food products. What digital solutions can overcome these obstacles? Yizhou Ma considered this question. The doctoral project of "Adaptive Control of 3D Food Printing" combined sensor technologies and predictive models to create robust adaptive control strategies for extrusion-based 3D food printing.

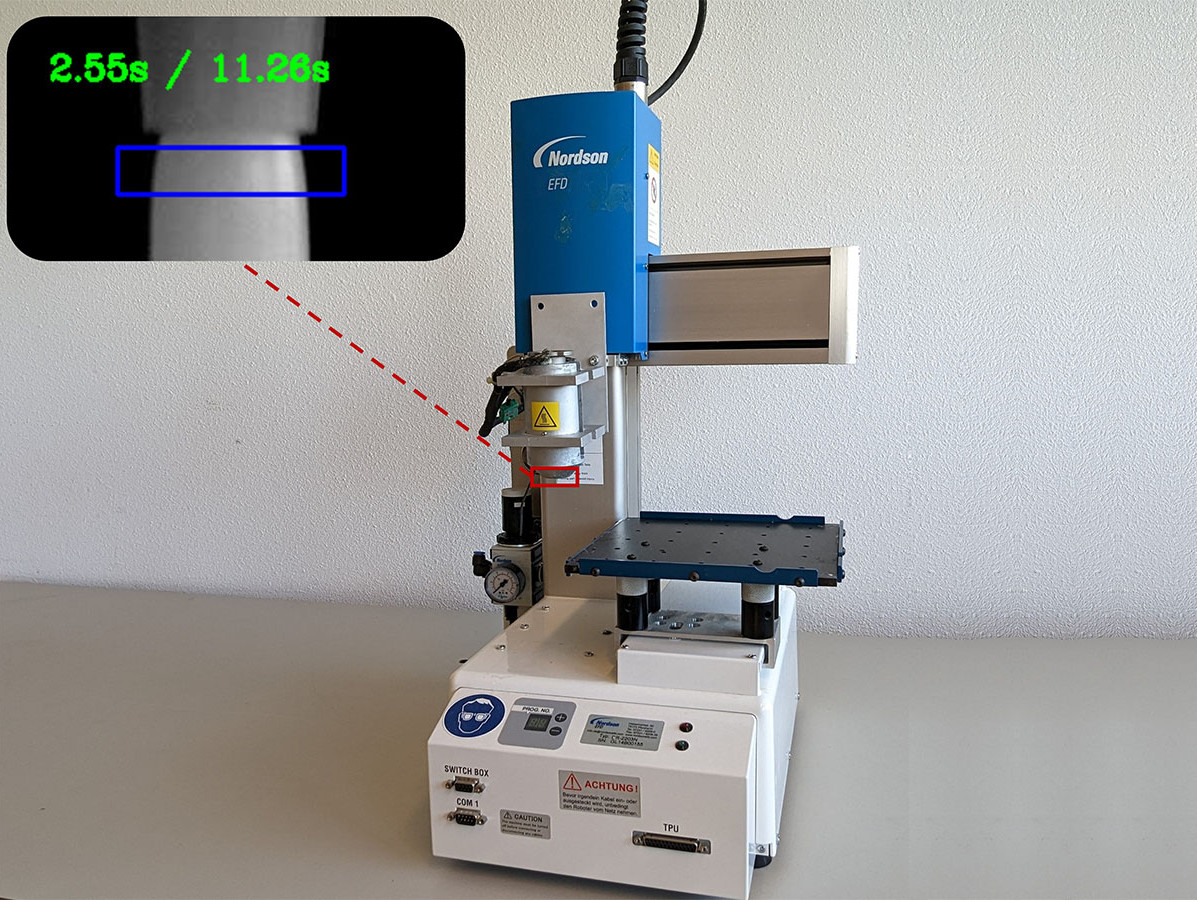

A desktop 3D food printer and a close-up of the print head during printing

Extrusion is a commonly used method for 3D printing food. In this process, food material is loaded into a syringe and dispensed through a small nozzle into filaments. These are applied layer by layer to create a 3D structure according to a digital design. However, proper control of food material flow can be problematic. This is caused by differences in the rheological properties of foods. In other words, the differences in the flow behavior, the shear-thinning property of different foods, under the influence of pressure and syringe geometry, can lead to variations in the flow of the food as it moves through the pressured syringe. Therefore, the various printing parameters must often be adjusted manually to achieve proper 3D food printing.

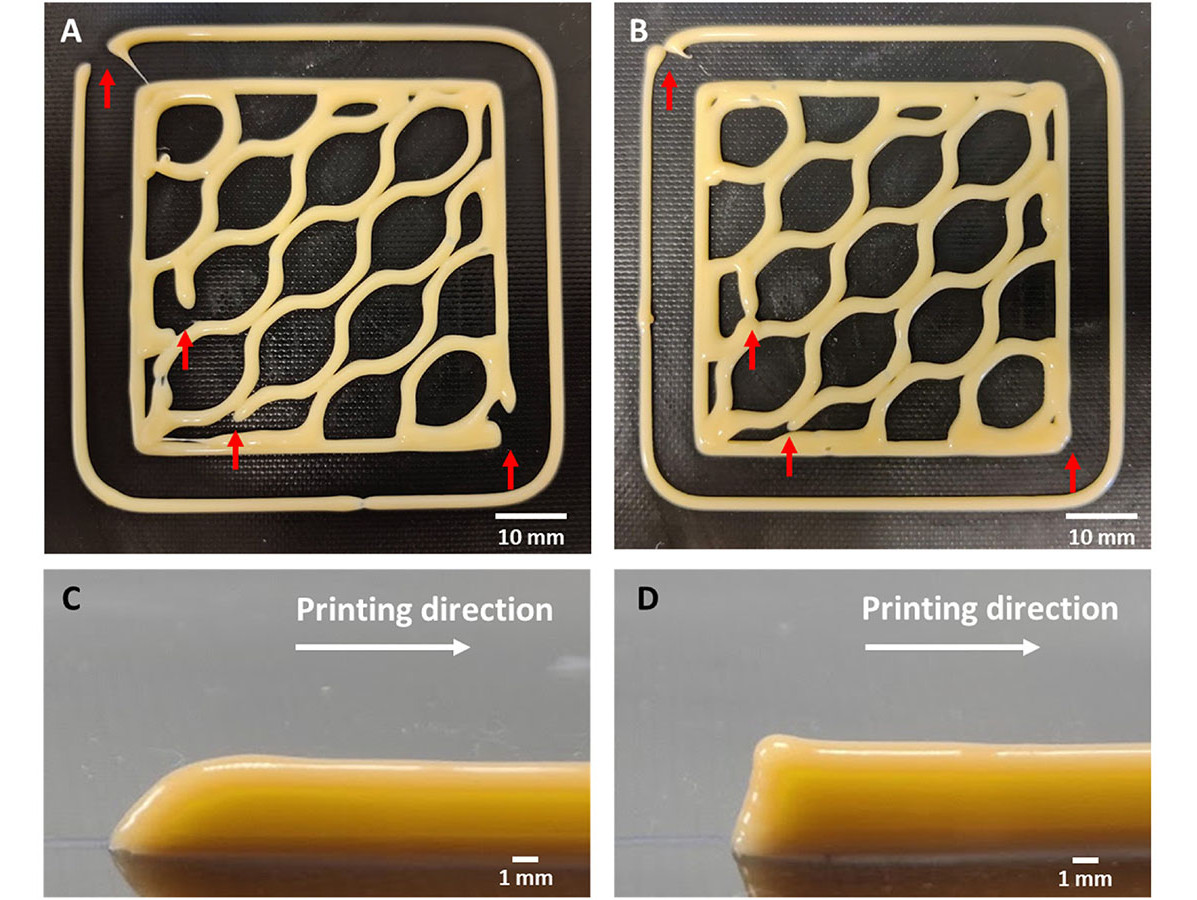

To streamline the optimization process and reduce development time, the researchers used computer vision: artificial intelligence that allows machines to interpret and analyze images and videos. They were specifically interested in measuring the flow rate of feed materials during the printing process. To do so, they placed a camera close to the print head to record the flow of the food material. Then they programmed custom-made computer vision software. This software can track changes in the food flow image by image. In doing so, they determined the dynamic food flow over time. They found that different food materials exhibited unique flow behavior during the extrusion process. The food flow started slowly and gradually reached an equilibrium velocity. The acceleration of the material flow varied; depending on the food material, the geometry of the nozzle of the 3D printer, and the pressure of the printer. By directly measuring the dynamic flow profile of a food material, the researchers were able to determine some printing parameters, such as the printing speed and printing temperature. They then programmed an automatic calibration step to determine the optimal printing speed for new printing materials. This material-specific calibration improves 3D printing accuracy with minimal trial-and-error experimentation. The researchers also converted the method into user-friendly computer vision software for existing 3D food printers.

Improved printing accuracy of cheese from standard 3D food printing (A&C) to calibrated 3D food printing developed by this study (B&D))

How can advanced sensor technologies, artificial intelligence and robotics contribute to addressing societal challenges around food security? This is being explored within the WUR Agro Food Robotics program by senior scientist Aneesh Chauhan and his team.

Digitizing a food process is complex, in part because of the natural variation of food compositions and the complexity of food processes. To develop an effective digitization strategy, it is critical to create hardware and software that work together in harmony. This implies the integration of various sensor technologies that can monitor physical, chemical and microbiological changes during food processing.

Computer vision is a technology for meaningful monitoring of physical and chemical changes of food. To properly implement computer vision applications, hardware (such as industrial cameras) must be coupled with sophisticated software algorithms to perform the necessary control actions. By implementing automated controls, it is possible to create so-called "feedback loops" to adjust processing parameters in real time based on them. The use of these types of adaptive controls optimizes and improves the efficiency of the food production process, also reduces (partly as a result) waste.

www.wur.nl

www.digitalfoodprocessing.com

www.sciencedirect.com

Main photo: ©guteksk7/Shutterstock.com

Source: Vakblad Voedingsindustrie 2023