Neerlandia Urk was founded in 1972 by brothers Herman and Albert Romkes and was taken over at the end of 2019 by five sons of the founders. Originally, this traditional fish company specialized in a wide range of North Sea fish, but over time, its product range has expanded to include various Atlantic fish species and salmon—mainly sourced from Norway. Nothing is too crazy; ‘impossible’ simply doesn’t exist here. Need a different type of packaging, shape, or size? Neerlandia Urk rises to the challenge.

Neerlandia Urk is, at its core, a processing company. North Sea fish, such as turbot, cod, sole, and brill—especially plaice—have been traded and processed here since 1972. For a long time, plaice filleting was the backbone of the business, but their focus has since broadened significantly. “We handle both fresh and frozen products in large volumes. In 2024, we processed around 13.5 million kilos of fish!” says Hendrik Post (29), nephew of one of the founders and responsible for sales in the Benelux. Next to him is Jan van Klaveren. He joined the company just two and a half years ago, but as the founders’ brother-in-law, he has been closely involved with the business for most of his adult life. His role includes overseeing financial operations, monitoring purchasing processes, and negotiating various aspects of the business. “I originally trained as a baker and pastry chef,” he explains. “After that, I got into accountancy. Even though everything here runs smoothly, a fresh perspective and new insights can be very refreshing. That’s part of why I was hired—to look at things from a different angle.”

So, I take it there's no place for a mindset of ‘We’ve always done it this way, so that’s how we’ll keep doing it’? Hendrik laughs: “Absolutely not! Change is always up for discussion. If I come up with a completely new plan and have thought it through properly, the older generation takes it seriously. Our philosophy is simple: you can only judge whether a different approach works if you’ve actually tried it. And if it does work, we build on it. Fortunately, the lines of communication within our company are short. If something comes up, we just walk over to each other and speak our minds. We don’t always have to agree, but we always find a way forward together. And we aim to stay ahead of the curve—to be innovative.”

“We’re always on the move,” Jan adds. “One of the biggest changes in recent decades was in 2000 when we moved into this new, modern building—quite unique for a fish company.”

The impressive entrance hall is shaped like a fish. Sunlight streams through the glass facade surrounding the staircase. The upstairs hallways feature glass art, sculptures, and paintings. “Most of these were collected by Albert,” Jan explains. “He often traveled with Herman, searching for new markets. My brother-in-law Albert’s incredible drive is why we’re in this building today. And as you can see, it’s still modern.” We walk past the courtyard, with sturdy picnic tables and lots of greenery. The first violas of the season are peeking through the soil. I take a glance inside the inviting cafeteria—again, plenty of greenery—and step into the fully equipped gym for employees (which, judging by the activity, is actually being used). The bright offices have windows overlooking the corridor. In one of the offices, an entire wall is covered with real-time camera feeds of the production areas. “From here, co-owner Jurriaan Romkes has a full overview and control of everything happening on the production floor. He can manage all the automation systems from this office,” Jan explains.

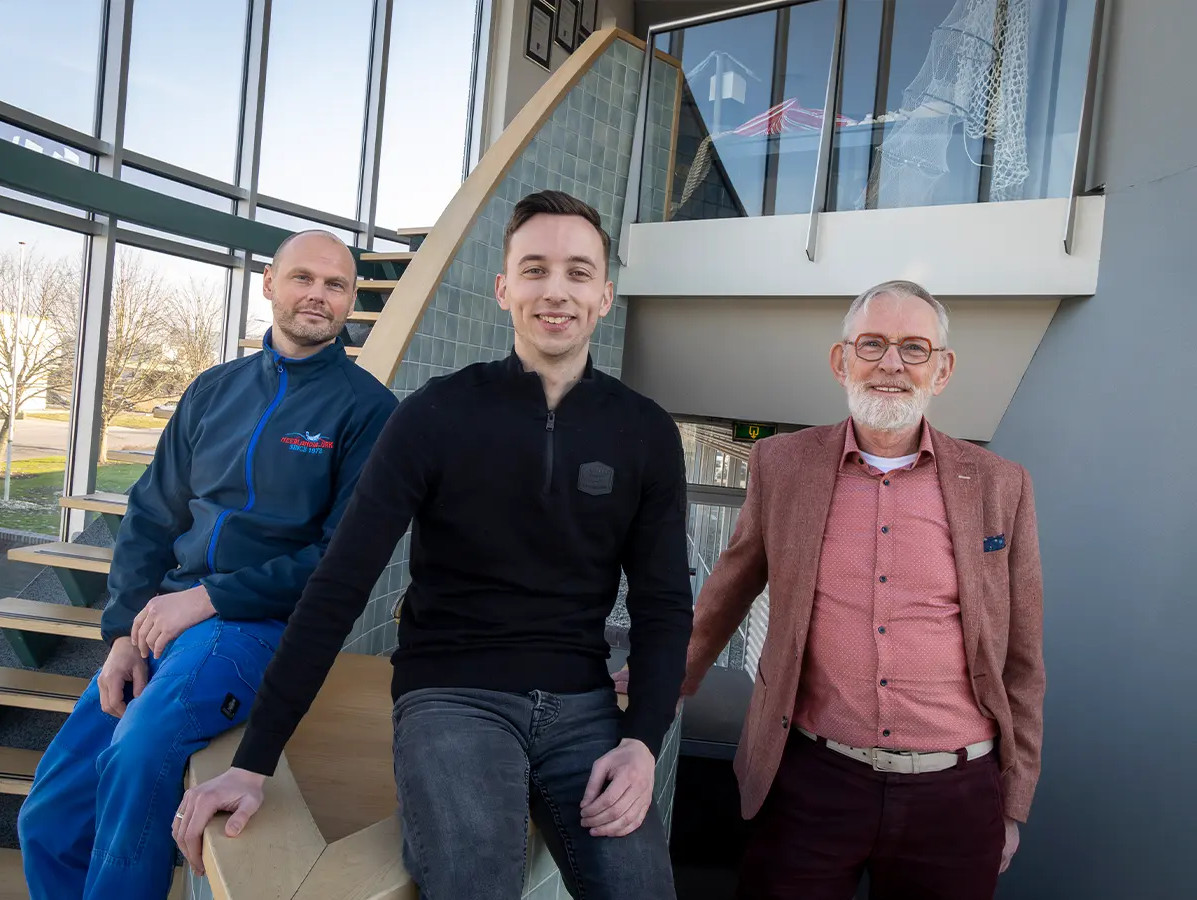

(from left to right) Riekelt Romkes (one of the five co-owners), Hendrik Post and Jan van Klaveren

But I’m not here to watch security footage—I want to see the real work. So, we move on to the locker rooms—spotless, with rows of dark blue lockers. We put on overcoats and shoe covers, put on our hairnets, and wash our hands. Then the latex gloves go on, followed by hand sanitizing, and then we step through the hygiene barrier into the cold production area—the beating heart of this company.

Some of the processing and packaging is automated, but fish processing clearly is a lot of manual work. In one area, skilled countless workers fillet plaice and flounder, while in another, large salmon are being processed. Further down the line, freshly cut fillets glide past—trimmed, glistening, and vibrantly pink. “Picture this,” Jan says. “Early in the morning, two truckloads of salmon arrive—20 tons per truck. By the same evening, that fish is filleted, packaged, and on its way out the door. The turnover speed is incredible… but it has to be. We work with perishable products.”

“That’s why food safety is absolutely critical,” Jan adds. “We hold one of the highest certifications in Europe. Multiple quality control staff constantly monitor hygiene, temperatures, and every other detail. Each month, someone spends an entire day checking, inspecting, and making sure everything runs as it should. It’s a significant investment, but it’s worth it. It gives us peace of mind.”

Hendrik has been involved in the company for years, working part-time. “That gave me a solid understanding of how things operate here at Neerlandia Urk. Albert and Herman are still around, and they set an example for all of us when it comes to hard work. And they still do with passion and pleasure. As the younger generation, we have a lot to learn from them.”

He says that the company was originally built around flatfish processing. But when availability declined, they had to adapt. Jan raises his voice over the hum of the machinery: “We can still source sole, but it’s becoming almost unaffordable for consumers. And the flatfish fleet keeps shrinking—partly due to EU regulations. For many cutters, fishing for traditional species is no longer profitable.”

“You wouldn’t believe some of the stories about fishermen being forced to scrap their boats. It’s devastating,” Hendrik agrees. Neerlandia Urk has also felt the impact of EU regulations: “With European fishery volumes declining, we’ve had to expand our reach. We now source various flatfish species from the Atlantic, such as Alaska plaice, yellowfin sole, and Greenland halibut,” Hendrik explains. “Salmon is also in high demand, with endless possibilities—fresh, frozen, or smoked. Eight years ago, we started importing fresh Norwegian farmed salmon. The market fluctuates, but salmon prices are generally more stable than North Sea fish prices. We process it in various shapes and sizes; as fillets, in portions and different trims.”

Jan laughs. “That’s a term that was new to me too a few years back. Trim A, B, C, and D refer to how much fat is left on the fillet. With a D-trim, there’s no fat left at all. The more belly fat removed, the ‘cleaner’ the fillet—and naturally, the more expensive. Delivering the best possible quality product is what we strive for. Our customers know that. We like to stay ahead of the game.”

Hendrik adds, “Our fish is mainly supplied to retail and foodservice, both domestically and internationally. Every customer has different needs and preferences. That’s why we’re developing software to provide tailored price lists for our clients. ‘Impossible’ doesn’t exist here. If a customer requests a specific trim that’s not yet part of our standard range, we’ll try to make it happen. And when we deliver top-quality fillets, and I get a happy message from a customer saying, ‘Hendrik, this is premium fillet!’, that gives me so much satisfaction. It makes me look forward to work every day. And I still get a thrill when I see them filleting plaice downstairs. Because that’s the foundation of Neerlandia. Because we offer such a complete range, we always have something to fall back on when market demand for a certain fish species fluctuates. We’ve built a strong, diversified foundation.”

Neerlandia’s forward-thinking approach is also evident in the recent overhaul of its cooling and freezing systems. As a result, the company has nearly eliminated its reliance on gas. “Most of our gas consumption used to go into heating water for cleaning. We use thousands of liters of water at 65 degrees Celsius for sanitation. Now, we use heat recovery from our cooling systems instead. I’d estimate that we’re down to just 15% of our previous gas usage,” says Jan.

Hendrik adds, “And then there’s our water treatment system. By pre-treating our wastewater before it enters the municipal system, we’ve reduced our discharge fees.” Jan hesitates, “We’ve had that since 2007, though!”

“So we were already ahead of the curve back then,” Hendrik grins, before turning serious again. “For us, waste simply doesn’t exist. In the past, everything was discarded, but now valuable products are made from it. Salmon heads, bones—they’re all sold. They can be used for delicious fish soups, fish oil, or animal feed.”

Jan adds, “They’re even experimenting with making leather from salmon skin. Amazing developments, right?” Even packaging doesn’t end up in landfill. “Salmon, for instance, is delivered in Styrofoam boxes,” Hendrik explains. “At the end of the day, these empty boxes are collected and fully recycled.”

Hendrik: “We’re a multicultural company, with employees from all different nationalities. One of our regular team members has been with us for over five years. He’s originally from Poland but has become a true Urker and speaks Dutch fluently. He even acts as our interpreter when needed.”

Jan: “We believe in taking good care of our people. Even small gestures can mean a lot—just having a conversation, asking how they’re doing. We also have a gym, we offer full meals three times a week, and we organize company parties and barbecues a few times a year. We do this for two reasons: we care about our people, but we also want to retain them! Like many others, we face labor shortages. If we don’t have the people, a robot will have to take over. And we are moving more and more in that direction.”

Jan: “I learn a lot from the younger generation, and they learn from me. But you have to be open to it. What I often see in other companies is that the 30- to 50-year-olds call the shots while the rest are left hanging. That’s not good—not for the company structure, not for its future. We need to work together. And this applies to the entire food industry: value experienced employees, embrace young talent, and blend expertise with fresh ideas.”

Photos: ©Koos Groenewold

Source: Vakblad Voedingsindustrie 2025