Sooner or later the production floor needs maintenance or refurbishment. It's never really convenient. Renovation and construction specialist Jackit works as flexibly as possible to keep business processes flowing.

"Shutting down production is the most expensive thing in the world. You don't want that. That's why we work around production as much as possible and also adjust in other ways," says Jack Pluim, director of Jackit from Beekbergen, which has developed into a construction and renovation specialist over the years. "At a meat processor, for example, where a renovation is planned and the floor is being replaced. To save time, we install stainless steel plates on the bumpers before the old floor is removed. This way we don't have to do that later." At other times, he finds loopholes in busy schedules where he does the necessary preliminary work in advance. In a big hurry? In that case, work continues 24 hours a day. "It's about thinking along with the customer."

Meanwhile, Jack's company has been operating for nearly 30 years and he has become a familiar face in the food industry. The range of customers is extensive. As is the work, by the way; from carving out and replacing old and moldy sealant to renovating and building walls, ceilings and doors.

Every customer is different. So is every project. That's why Jack always starts by surveying on-site what needs to be done. In consultation with the company in question he makes a planning. A global one, because in practice things can change. "Usually things run differently. There is always more work to be done because, in the process, you come across things that should be addressed immediately," he knows. Jack is always present at the beginning, and apart from that he can rely on his team of around 20 people. Together they respond to various questions from the food industry, an industry that is of course subject to various developments. With regard to food safety, for example.

"Hygiene has become increasingly important over the years," Jack notes. "For example, the emergence of diseases demands a lot from the factory environment. In the meat industry, we still encounter a lot of tiling. That used to be common. The issue is that listeria bacteria can settle in the joints. Furthermore, loose coating on isolation panels at food plants is a common problem." For such situations, as well as to give bacteria less of a chance, Jackit has a solution in the form of bacteria-resistant panel systems of the Sealwise and Wonderboard brands. For each situation, the best suited option is chosen.

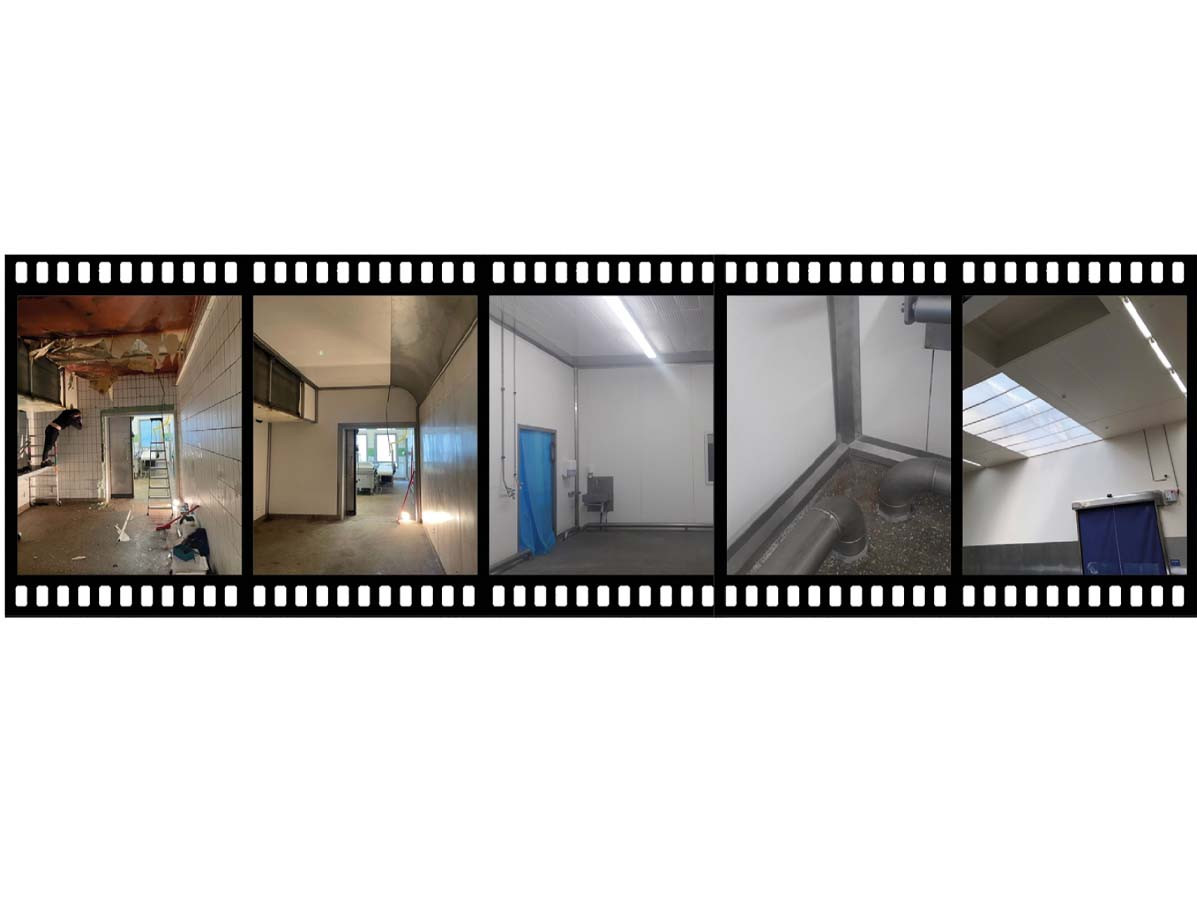

In order to serve clients well, the Beekbergen-based company regularly joins forces with other parties. For example, Jack is taking on various renovation projects with the Ruys Group. Recently, Jackit also began offering steel constructions thanks to a partnership with Van den Hul Staalbouw. He is currently building the structure of a cold store in the distribution center of a grocery delivery company with this partner. "Another new construction project is the airlock we are building between a cold store and a freezer department elsewhere in the country. There, by the way, we are also carrying out a renovation. We're taking on all sorts of operations."

Whether it's renovation or construction of new buildings, it's often work full of challenges. The biggest is usually the time factor and getting the job done on time. "Fortunately, we are flexible enough to accommodate that too, by 'shifting' employees. That way, with an extra man, the deadline is still met," he says. It suits Jack to do his work under special circumstances. It is precisely those jobs that no one wants to take on and that seem practically impossible that give him the greatest satisfaction. Or as he puts it himself: " Covering a square empty cell without any strange corners with panels is something almost anyone can do. It gets fun when it's tricky and one has to go around, over and behind machines. The trickier, the better. The guys who work for me think so, too. In those situations, there is just as little time and it has to be right the first time. The work has to be perfect. I would love to come back to a client three years later. But for a new project; not to fix my own mistake."

Photo Jack Pluim: ©James Media: Marcel van Engelenburg

Source: Vakblad Voedingsindustrie 2023