The VanDrie Group is extensively innovating in the veal sector: in regards to animal health and animal welfare, in improving food safety and production processes and in putting new concepts and brands on the markets. We hereby present a talk about the origin of JAN and the vision behind Gourmet.

A fresh brand and a new concept

“The idea for JAN was born from the increasing demand for convenience, which we as VanDrie Group would like to meet”, Patricia van Krieken, manager of Marketing and Communication at Stichting Promotie Kalfsvlees (Promotion of Veal Foundation), starts, “We asked ourselves; would there be a market in the Netherlands, Germany and Italy, our largest sales market and domestic market, for a veal burger? And not just any veal burger, but a quality hamburger, without additions, only with a little salt and pepper made from the best pieces of meat of carcasses without specifications. After all, only then we can guarantee constant quality.”

Establishing a brand in the world of meat is unusual. “Consumers are not used to branded meat”, Patricia continues. “This is why we decided to have a large qualitative research carried out by Imagro, a research firm specialised in questions about AgriFood and Environment. There’s an energised and innovative climate amongst its students that come from all walks of life. Very inspiring.” The results of the research provided a lot of insight. For example, what motivates people to choose a quality hamburger and where and when they decided to purchase it. There were also large differences between the eating cultures of the Dutch, Germans and Italians. “The Dutch eat a burger mainly as part of a main meal”, Patricia illustrates her point, “while Germans and Italians mostly eat them as a snack”.

The VanDrie Group-team got to work with this information. They analysed what was already on the shelves and how a new brand could distinguish itself. “Nearly all existing packages have a picture, which is something we wanted to do differently. We issued a pitch amongst advertising agencies in the Netherlands that operate worldwide. An international character made it easier for us to research how the packaging would be received abroad.”

And thus, about a year after the first idea, a new brand was born: meat in a sporty package with a typically Dutch way: JAN. A name with a clear link to the family history of the VanDrie Group, with Jan van Drie as the founder. “A lot of time and effort was also put in the design of the new line of hamburgers that year. It’s about so many aspects: about food and machine safety and an optimal production process. About the way the meat is ground, how large the meatball must be, how to flatten it and then package it, for which we chose the innovative skinpack method. Within the flap, the consumer will find information about Jan and the story behind it.”

By now, the brand has an extensive assortment with diverse sous-vide prepared technical parts including spareribs, shoulder stake, osso buco and jowls, but also with stewed meat. “Consumers don’t have, or don’t take, the time to prepare these products at home. Yet they really like putting this meat on the table. The flavours are kept neutral, so the consumer or chef can season them at home or in the kitchen.”

‘Consumers are not used to branded meat’

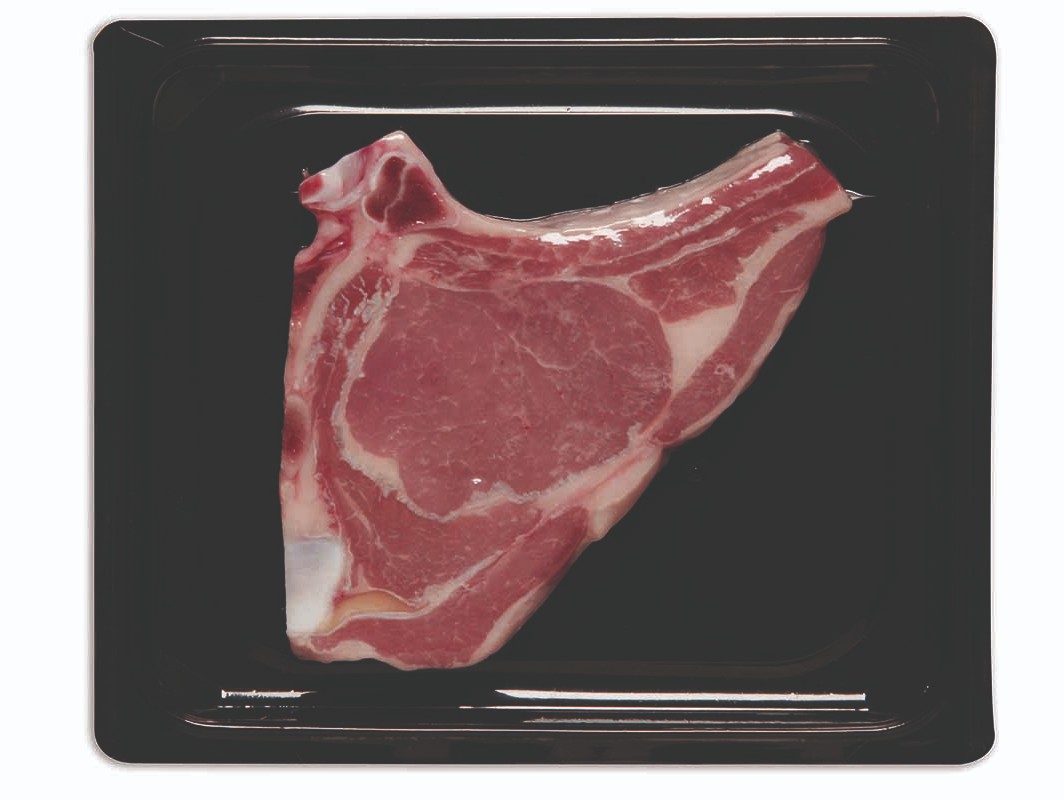

VanDrie Group also supplies ‘Gourmet’. “This is a type of brand/concept, we can adapt the products to the individual wants of the client”, Patricia explains. “The assortment consists of traditional favourites like veal escalope and cutlets to delicacies like veal sweetbread and veal jowls. All products are packaged in an individual skinpack package, provided with a sleeve. Contrary to JAN, we did choose a picture here: a suggestion on how to serve it. The recipe is on the sleeve.

While the processes of butchering, deboning and further portioning are further separated in technical parts of most companies, it all comes together under one roof at the VanDrie Group with Gourmet. Why? “Many reasons”, Patricia says. “By keeping it all internally, we keep better control of the quality. Processes are inspected increasingly strictly, both our own inspections and those by third parties. Additionally, by keeping everything under one roof, we can react to situations faster and limit transport. There’s a laundry list of plusses.”

Additionally, Peter’s Farm is also produced completely in-house. This way, VanDrie responds to a new trend. “The current client only buys what he needs”, Patricia says. “That influences the working method. Years ago, whole carcasses or half carcasses were sold, now you see a shift in the production to strongly customer-oriented products. The consumer largely makes his decision at the store. Packaging and product must therefore look attractive, else they won’t buy it. Skinpack packaging is ideal for this. After shaping the lower film in preformed moulds, we seal the product with special upper film. This closes around the product like a second skin and keeps the product in place. The juices can’t leak out, the shelf life is extended and the consumer can better judge the colour and quality of the veal. By now, we have mastered the technology so well that the skinpack packaging is also suitable for products with sharp edges, such as veal cutlets.”

Source: © VanDrie Group