It is always raining reports at the Dutch Food and Consumer Product Safety Authority (NVWA): Salmonella in meatloaves, smoked sausages and in basil spice spreaders, Listeria monocytogenes in frozen corn, allergens in products that do not belong there. So why do things go wrong so frequently? The answer can often be traced back to the incorrect implementation of cleaning and disinfection procedures. Back to basics.

To prevent microbial contamination and cross-contamination of allergens, it is essential to clean equipment, tools, surfaces and the work environment properly and in the right way. But what is 'proper'? And what is 'the right way'? For the answer, we go back to basics. The purpose of cleaning and disinfection is to remove dirt, thus eliminating cross-contamination with allergens and/or contamination by microorganisms in such a way that:

In the food industry we go through the following cleaning and disinfection phases: it starts with the removal of all present product residues and visible dirt; then a cleaning agent is applied, which after a set soaking time is rinsed/sprayed away with water. Then follows the application of a disinfectant to the clean surfaces, with again a soaking time, and the removal of this agent by rinsing with (microbiologically) clean water. Once dry, equipment and space are again available for production.

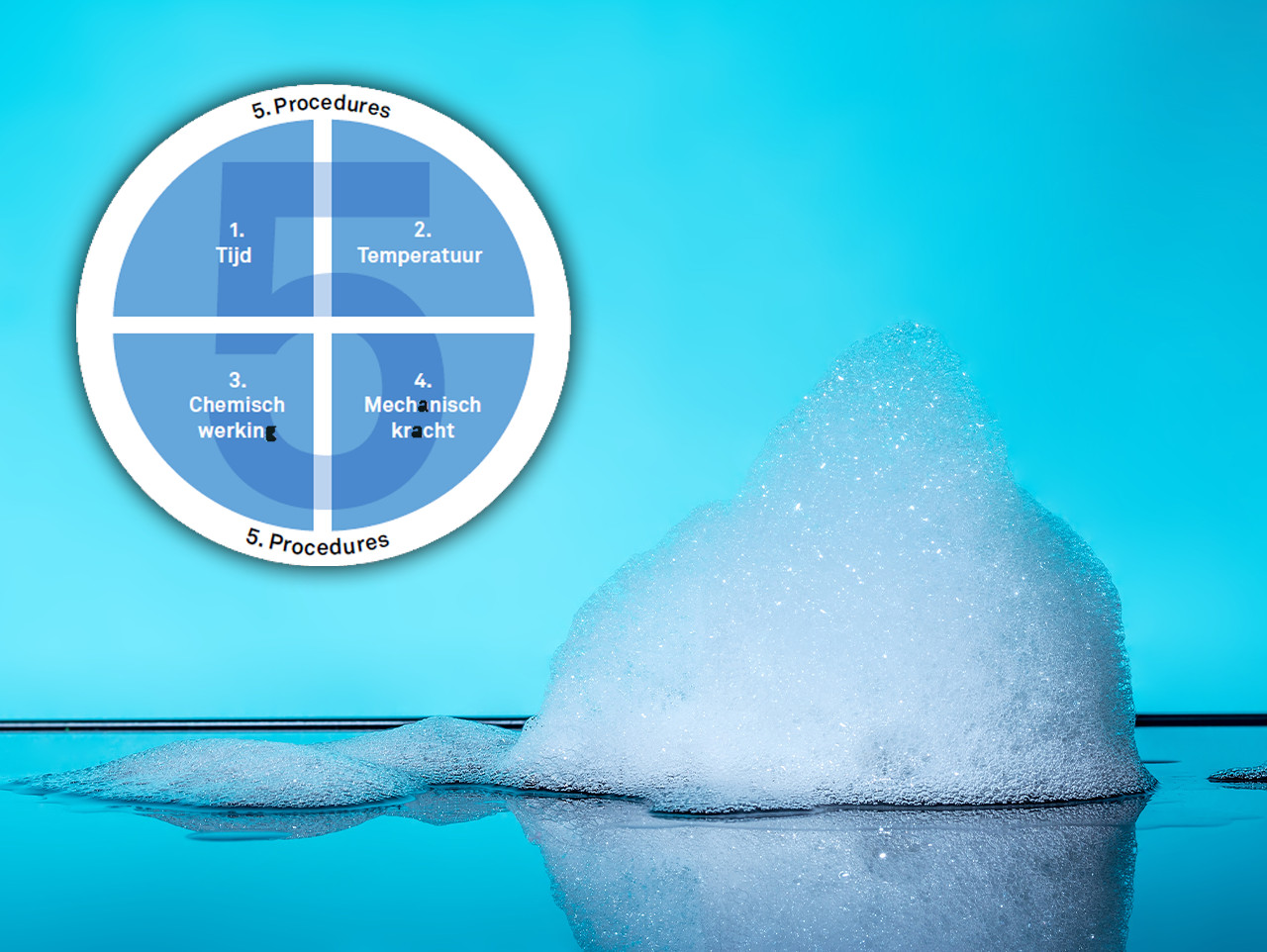

Sixty years ago already, Dr. Herbert Sinner, head of detergent development at Henkel, defined four universal factors that determine the success of every washing cycle: chemistry, mechanical force, temperature and time. He brought these together in the well-known Sinner Circle. These factors influence each other and can change in magnitude. Meanwhile, a fifth factor has been added to this basis: procedures (see Figure 1).

Time represents the length of time that a cleaning agent or disinfectant (chemical) is able to do its work in the contamination.

Temperature influences the cleaning process. As a rule of thumb, the higher the temperature, the better the result. However, the temperature is limited from the point of view of safety (risk of burns), corrosion risk, protein coagulation and the temperature of the various seals (think of sealing rings).

Chemical action is based on the effectiveness of the detergent/disinfectant used in relation to the contamination present and the concentration used. In general, the more mechanical action is applied, the greater the effectiveness of the cleaning.

Mechanical force can range from scrubbing with a brush to spraying with a high pressure water jet.

The Procedures accurately describe the entire cleaning and disinfection protocol from A to Z. Common sense says "Make sure you have a good cleaning at the end of the production run! A common mistake. Proper cleaning and disinfection together form the starting point - an essential part - of every production process. The procedures systematically describe when and how cleaning and disinfection must be carried out, what agents must be used, what steps must be taken in succession, in what time frame, and so on.

If cleaning and disinfection procedures are not effective enough, or if the equipment is not designed hygienically, microorganisms, in addition to product residues, can adhere to the surfaces and form a biofilm. Biofilms can form and grow within just a few hours. Once formed, they are difficult to get rid of and become a source of contamination for food products. The use of enzymes in combination with disinfectants is one of the effective strategies against biofilms that have already formed or are about to form (Delhalle et al. 2020, WFBR own unpublished data). Disinfectants are also used against biofilms. One example is chlorine dioxide (ClO2). This is a fast-acting, broad-spectrum, antimicrobial agent. To use it in the food industry, the necessary approvals are required for the specific purpose for which they are used.

Wageningen Food & Biobased Research (WFBR) studied the effectiveness of ClO2 against biofilms in two strategies:

1. How effective is the use of ClO2 at higher concentrations against already formed biofilms? Conclusion: 5 ppm ClO2 was needed to obtain 1 log reduction in the biofilms of Listeria monocytogenes and Salmonella Typhimurium. (1 log reduction means that 9 out of 10 bacteria are inactivated).

2. How effective is the use of ClO2 when used repeatedly at lower concentrations, such as 0.4 ppm? This concentration was found to be insufficient at a single exposure to inactivate the cells within the biofilm, which are protected by the biofilm's extracellular matrix. It was, however, effective against free-floating - planktonic - cells of both microorganisms tested (unpublished data WFBR). When used as a technical aid, for example, the low concentrations of ClO2 can inactivate free-living cells. Thus, this may contribute to the prevention of biofilms because cells - before reaching the surface - are no longer viable.

The choice of cleaning method and disinfectant depends on the food production area in which you want to operate. Factors involved in the choice are:

There are different ways to apply the disinfectants, for example, in the form of a liquid or a mist. The mist can be wet or dry, depending on the size of the droplets in the air. The larger the droplet size, the faster the droplets condense on the surface. In one of our studies, we compared the efficacy of commonly used disinfectants, namely peracetic acid (PAA) and hydrogen peroxide, when applied in the liquid form versus the mist [Hayrapetyan et al., 2020]. The study showed that the disinfectants then have the same inactivation rate against the spores of Geobacillus stearothermophilus on the surface of stainless steel. The condition is that the mist is given sufficient time to saturate the air and surface with the spores. Atomization of a 0.06% solution of PAA resulted in more than 5 log reduction (or inactivation of 99,999 out of 100,000) of spores in 10 minutes.

Dry cleaning is mainly used in bakeries, as the equipment used there is usually not designed for wet cleaning. This dry cleaning is often done manually and is therefore time consuming. Bakery products are heated during production, but the baked products can become contaminated with airborne microorganisms during cooling and before packaging. One can assume that it is tempting to clean and disinfect less frequently in the areas before baking compared to the areas after heating. It is expected that proper and frequent cleaning in the rooms before baking will lead to less post-contamination during packaging. Preventing contamination also prevents food waste. This again underlines the importance of proper cleaning and disinfection as a starting point of any production process.

Efficient and proper cleaning and disinfection are crucial pillars for a successful and long-lasting existence of a food company. It contributes to the prevention of recalls due to food unsafe situations such as microbial contamination or cross-contamination with allergens. It is a good thing if all layers of the company are aware of this.

Main photo: ©Macrovector/shutterstock, bubbles: ©HappyRichStudio/shutterstock

REFERENTIES

- HAYRAPETYAN ET AL. 2020. INACTIVATION KINETICS OF GEOBACILLUS STEAROTHERMOPHILUS SPORES BY A PERACETIC ACID OR HYDROGEN PEROXIDE FOG IN COMPARISON TO THE LIQUID FORM. (HTTPS://DOI.ORG/10.1016/J.IJFOODMICRO.2019.108418)

- DELHALLE ET AL. 2020. EVALUATION OF ENZYMATIC CLEANING ON FOOD PROCESSING INSTALLATIONS AND FOOD PRODUCTS BACTERIAL MICROFLORA. HTTPS://DOI.ORG/10.3389/FMICB.2020.01827

- HTTPS://WWW.WUR.NL/NL/ONDERZOEK-RESULTATEN/ONDERZOEKSPROJECTEN-LNV/EXPERTISEGEBIEDEN/KENNISONLINE/OPPERVLAKTEBESMETTINGEN-IN-DE-LEVENSMIDDELENINDUSTRIE.HTM

Source: Vakblad Voedingsindustrie 2021