The economy is improving. Companies are gradually more willing to invest again, including in the purchase of new hygienic equipment. But what should they choose? This article examines the CIP system: what are the benefits and risks? And how can companies manage the CIP process?

Cleaning is extremely important to prevent contamination and hence guarantee food safety. But how should you approach cleaning? Companies can choose between manual, semi-automatic or fully automatic cleaning systems, or a combination thereof. In the case of manual cleaning systems, people are responsible for the effectiveness of the system and ensuring safety, which is why more and more companies are opting for automatic cleaning in the shape of a CIP system.

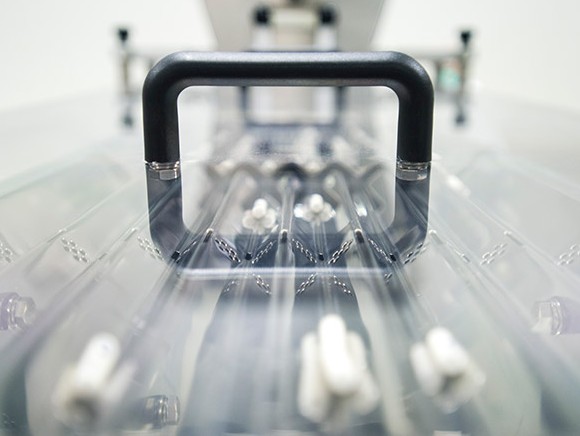

CIP is a technique for automatically cleaning an object without components having to be removed, moved or disassembled. There are various types of CIP, such as:

a fully automated CIP system including circulation of cleaning fluid and reuse of rinsing water;

an automated ‘lost CIP’ in which everything is directly drained off as waste water;

a semi-automatic CIP in which the equipment is used as a CIP tank.

The decision for a particular CIP system depends on factors including the available budget and the size and complexity of the equipment. The Sinner Cirkel tool helps companies to determine what they need to achieve optimal cleaning. The factors of temperature, time, cleaning agent and mechanical force must all be in balance in order to optimise the cleaning effectiveness. And, in the case of complex equipment, another important factor must be considered too: the sequence in which the sections are treated during the CIP programme. The sections must be pre-washed, cleaned, rinsed and, if necessary, disinfected in the right order so that clean sections do not become contaminated.

In practice, ineffective cleaning is often the cause of product failure and product rejections, according to Brenda Kerkdijk who, in her role as a consultant, helps companies to validate systems including CIP. Brenda: “We’re seeing knowledge gaps in terms of how CIP systems work and how effective they are, at all levels: operatives, technicians and management. Furthermore, CIP systems often turn out to be poorly designed and there is often a lack of ‘change management’ methodology. A broken or suboptimal cleaning system can pose a risk to food safety and the company’s reputation such as through allergen contamination and/or the spread of pathogenic microorganisms. That’s why it’s extremely important to validate the CIP system. But unfortunately it still isn’t being done often enough.”

Brenda: “One of my customers wanted to install a CIP system in a new piece of equipment. The machine builder prepared the design. The functionality and cleanability of the machine soon presented a number of dilemmas. The machine builder had placed a spray nozzle in every bend and behind every valve, based on the idea of ‘more nozzles means a cleaner end result’. I was asked to evaluate the effectiveness of the CIP system. Based on my theoretical calculations, it turned out that the system required six times more water flowing through it than the pipes and pump could cope with. So what were the possible solutions?

Fewer nozzles

A smaller nozzle type

Splitting the CIP into sections

Cleaning some parts by hand

Installing bigger pipes and a CIP pump with a higher capacity

Designing the CIP to function with a lower flow.

My customer decided to use a different nozzle type, but the equipment has always remained problematic in terms of cleaning. So the conclusion we can draw is: to avoid high costs and inefficient cleaning, it’s important to involve CIP experts early on in the process. After all, they’ve got the right knowledge and experience.”

To optimise the effectiveness of a CIP system, it is very much a case of ‘to measure is to know’, and a CIP effectiveness audit is the ideal tool for this, advises Brenda. The audit is made up of two parts:

A static audit to gain an overview of the set-up of the CIP system. This covers questions such as: How is the system constructed from a technical perspective? What are the lengths, diameters and other dimensions of the pipes, including bends?

An active audit to gain an overview of the CIP cycles. One or more cycles are run to allow measurements to be taken and data to be recorded, plus processes are visually inspected.

The results of the audit are presented in a report and – if relevant – an improvement plan is written containing concrete areas for improvement.

Managing CIP is an important task. Brenda’s advice is: “The first step in safeguarding cleaning performance is to correctly set and monitor parameters. Automating the system ensures that the fundamental requirements for effective cleaning are met at all times. Additionally, employees must be kept up to date in terms of the latest CIP-related knowledge. It’s the management’s job to provide the right resources so that cleaning standards can be continually maintained. Cleaning is a matter of life or death, so don’t allow CIP to become a silent killer. And what I mean by that is: don’t simply assume that the system works properly, but instead take responsibility and actively ensure food safety.

Photo: Brenda Kerkdijk

Source: © Jeroen Pulles