When it comes to cleaning and disinfection, what are the biggest challenges for the food industry? Where do things go wrong? Sometimes, an ‘outsider’ can see things more clearly than factory managers themselves. How can the food processing industry improve standards of cleaning and disinfection? Here, six experts share their insights.

This article presents the opinions of six experts, each with thorough knowledge of the food industry from their own perspective. Six conversations providing different solutions and useful tips, but echoing through all of them is one strikingly uniform statement: the universal problem within the food industry is that manufacturers do not regard cleaning as an essential part of the production process. In other words, there’s work to be done.

“Cleaning is not ‘sexy,’ it’s seen as a low-interest topic and always has been,” is how Leo Frings, Sales & Marketing Director at Qlean-tec, sums up the trend. (Qlean-tec develops and supplies professional cleaning materials, and provides advice and support.) “Naturally, as a company that’s crazy about cleaning, we strongly beg to differ! Things like production efficiency, routing and packaging receive plenty of attention, but when it comes to cleaning the reaction is: ‘Oh yeah, we should maybe look at that too’. In actual fact shelf life, freshness and product quality are extremely closely linked to hygiene. If the cleaning and disinfection activities are not done properly, the result can be costly problems further down the line. Despite this, we’ve noticed that companies find it difficult to create employee engagement in practice.”

Patrick Sulèr, Sales Manager at Havantec Food Equipment (a supplier of stainless steel equipment for the food sector) adds: “Besides that, we’re seeing ever-tighter regulations for food safety and hence cleaning and disinfection. Whereas a wash basin with a soap dispenser might have been enough in the past, that’s no longer the case. The keywords are control and manageability. You have to accept that workers will do all sorts of things to get around the hygiene regulations and hygiene sluices, which is why the equipment has to be foolproof.”

Gert Visscher, Director of Eco2Clean (a supplier of high-quality cleaning and disinfection agents for the food industry, and an expert in hygiene and cleaning support), is another specialist who sees positive developments: “More and more food processing companies want to do things properly. They are asking themselves whether the cleaning is well organised within their company: am I doing it well enough and smartly enough, can costs be reduced? We can help them to answer these questions, starting with analysing their approach to cleaning. We look at how and where they can do things more intelligently and more efficiently. We sometimes come across odd situations, such as departments that are listed in the cleaning procedure when they don’t even (or no longer) exist, or departments that are cleaned despite not being listed in the procedure.”

Leo Frings: “One thing that complicates the issue is that everyone thinks they know all about cleaning; after all, they do it in their own home too. What many people fail to appreciate is that cleaning a food production environment is completely different from cleaning their own kitchen. We often come across knowledge gaps on the work floor. What is cleaning and what is disinfection? The effectiveness of professional cleaning agents and materials is both overestimated and underestimated.”

René Bakker, Key Account Manager Food Industry at Hago (a family-owned company in cleaning services and specialist cleaning, including in the food sector), agrees: “During the financial crisis many companies were forced to downsize leading to redundancies. More and more manufacturers started doing their own cleaning, but they underestimated what that work entailed. Now that the economy is improving, they are keen to outsource the cleaning activities again because they realise that cleaning is a specialism in the food industry. Moreover, the flourishing demand is resulting in more production uptime, which means less time can be scheduled for cleaning and disinfection. That presents a big food safety risk. However, there is a shortage of well-qualified cleaning staff for the food industry – even we’re finding that sometimes. Robotisation and automation of cleaning activities could go some way towards solving this problem, but you can’t automate everything.”

Marcel Wilmink, General Manager of Bactoforce (a company specialised in the inspection of tanks, heat exchangers, pipes, spray dryers and other machinery and systems) likewise mentions ‘lack of time’ as a risk factor: “Cleaning and disinfection of production equipment such as tanks, silos, evaporators and dryers is often done using a cleaning-in-place (CIP) system and one or more CIP nozzles. The growing lack of time is putting CIP under increasing pressure; things have to be done more efficiently and more effectively. Older systems are not designed and/or not validated for that. Additionally, a system can sometimes no longer be fully cleaned due to a defect such as incorrect pressure and flow at the CIP nozzle, or an insufficient number or incorrect positioning of the nozzles. There might also be an object (such as a stirring mechanism) located between the nozzle and the wall, preventing the CIP system from being able to reach all areas. People sometimes try to solve defects by running the CIP for longer. Hard-to-reach places can eventually be cleaned by spatters of CIP fluid, but it’s a costly makeshift solution.”

Gert Visscher emphasises that Eco2Clean’s added value lies in its provision of continuous insight into the quality and organisation of cleaning and hygiene: “After conducting a baseline measurement we monitor the process periodically and take random samples to check progress. We turn up unannounced, both during the day and at night. Our aim is to optimise the cleaning as a whole. We use hard data to show companies the consequences of any shortcomings. To optimise the communication between the cleaning crew and Production, we’re developing the HIMS app, which makes it even easier to document situations – especially with photos. The cleaning crew can gain a quicker view of what Production has noticed. We will start testing the app in November and it will be launched at the start of 2018.”

Leo Frings: “Most cleaning agents on the market do what they are designed to do. But how exactly should they be used, and when, why, what for and how long? We set ourselves apart by providing our customers with advice and support, such as to tackle biofilm which we can identify using our own detection method. By making biofilm visible, you help people to realise that it really does exist. After that, they’re more open to learning more about its consequences. At Qlean-tec we can also remove biofilm, plus the cleaning method we use also prevents it from coming back so quickly.”

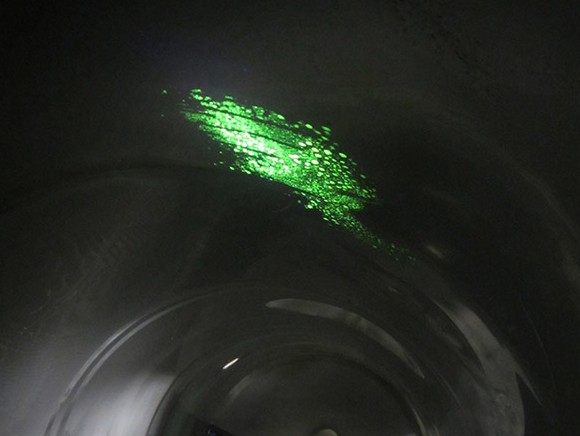

Marcel Wilmink: “We use the riboflavin test to validate the cleanability of systems and highlight defects. This involves applying a thin layer of riboflavin solution on the inner wall of the system. In the case of larger systems this entails entering the system, not only to apply the fluid correctly but also to observe the results. After activating the CIP installation for a brief predefined time, we then examine the system using UV light to detect riboflavin residues. This reveals the areas where the cleaning is below par. We find defects in 40% of new systems, and there is room for improvement in more than 60% of older systems. Whenever we come across a system that falls short in terms of cleanability, we offer specialist advice on how the system can be adapted.”

Patrick Sulèr: “Many employees live for their breaks, and if they can extend them a little by dodging hygiene protocols – such as by disinfecting one hand instead of both, or by passing through an access gate in pairs or even jumping over it – they will. That’s why manufacturers integrate all kinds of checks, e.g. strategically located cameras, hygiene sluices that are impossible to avoid, or an electronic chip that the employee carries on their person. The chip is linked to hygiene apparatus, which it unlocks. The chip system enables registration of how often a person passes through a hygiene sluice – e.g. for breaks or to go to the toilet – and above all how long that person is gone for. At ITEC they are responding to this trend proactively by devising smart solutions. One good example is the Mano-vision, a new ITEC system for hand washing and disinfection. Whereas employees could bunch their fists, preventing the disinfection fluid from reaching everywhere, or could just wash one of their hands, they are now forced to disinfect both hands including spreading their fingers. This is monitored by a camera, and you’re only allowed to continue if you’ve used the equipment correctly.”

Jason van den Broek, Key Account Manager at Dyson, who knows all there is to know about hand hygiene, continues: “Hands are a breeding ground for harmful microorganisms; over 80 percent of infectious diseases are spread through touch. Damp hands can spread a thousand times more bacteria than dry ones, which means it’s just as important to dry your hands thoroughly as it is to wash them. There has been a lot of discussion in the media about what ‘hygienically dry’ actually means, and the flames of that discussion have been fanned by the paper industry. They see the sustainable Airblade technology as a threat, which is why they regularly publish misleading research findings which call into question how hygienic Dyson Airblade hand dryers are. Thankfully food industry managers don’t pay a lot of attention to this; for them, the fact that our jet dryers are HACCP-certified is what matters. Besides that, more and more companies are looking for a more sustainable hand-drying solution.” In practice, the reality is that the use of paper towels to dry hands leads to the same problems everywhere: high costs, empty dispensers and a mountain of waste. Waste bins soon overflow because no one pushes the paper towels downwards, often resulting in used paper towels littering the floor around the bin. A growing number of food companies work around the clock, 24/7. The dispensers soon become empty at peak times, when lots of employees are washing and drying their hands. But regular hot-air dryers do not offer the best solution for the food industry either; they are based on outdated technology which draws air from the room itself and blows it onto the hands. “Our hand dryers are fitted with HEPA filters to remove 99.9 percent of the bacteria and viruses from the air. We supply a continuously operational system that doesn’t generate waste. It doesn’t need to be refilled and no rubbish bins need to be emptied. It dries your hands in 12 seconds – effectively and hygienically.”

Marcel Wilmink: “When you’re buying a new machine or system and signing a purchase agreement with the supplier, make sure to include a clause that the system must be thoroughly cleanable. Ask for proof of cleanability, and invest in a good inspection. Then you will benefit from efficiency throughout the whole useful lifetime of each CIP system.”

René Bakker: “As a food processing facility you must ensure that you get the basics right: the water must be at the right temperature, there must be enough drains in the right places, and so on. You should think carefully about cleanability in the design phase of machines and buildings. ‘Easy and safe accessibility’ is the fundamental requirement for effective cleaning.”

“I’m hugely in favour of the board of directors taking a more active role,” adds Gert Visscher. “Cleaning and disinfection must have sponsorship at a higher level. Only then will it become an essential part of the overall business approach. There are lots of gains still to be made in this area.”

Patrick Sulèr: “It’s unfortunate that cleaning and disinfection is often seen as a necessary evil. My advice to the industry is to not to regard it as just a cost, but instead to take a much more future-oriented look at your hygiene situation. Stay a step ahead of the food safety and quality authorities. Honestly, investing in hygiene is crucial for business continuity.”

“Every time that the topic of food safety hits the headlines again, it causes a knee-jerk reaction,” concludes René Bakker. “That’s a shame; it should be a continuous process. Safeguard the continuity of your cleaning and disinfection activities, of how they are managed and of your employee training. Cleanliness should be your starting point – part of the production process – rather than an afterthought. Don’t wait until the end to decide how much budget you’ve got left over for it, but instead begin by working out how much it will cost to ensure your manufacturing facility is clean.”

Source: © Qlean-tec, Havantec, Eco2Clean, Hago, Bactoforce en Dyson