Biofilm cannot be smelled or felt, cannot be traced using conventional measurements such as ATP or Agar plates, and cannot be removed using traditional cleaning and disinfection agents. Maik van Leijden of Christeyns: "Biofilm is a time bomb."

You have been working for years with a fixed group of cleaners and the same cleaning and disinfection agents. Your factory is fantastically clean... And then suddenly you measure a microbiological contamination in your end product, such as Listeria, Salmonella or Campylobacter. You talk to your cleaners about it, choose different or stronger cleaning agents, and it's gone. "Better said: it seems to be gone. Because after a while you measure microbiological abnormalities again. Then it is very possible that somewhere in the production process you are dealing with biofilm." says Maik van Leijden, Sales Manager Food Hygiene at Christeyns. He has over twenty years of experience in the food processing industry and explains how a biofilm can open up, releasing the bacteria underneath, but can also close again. "Closed, everything seems fine, but you are actually dealing with a time bomb."

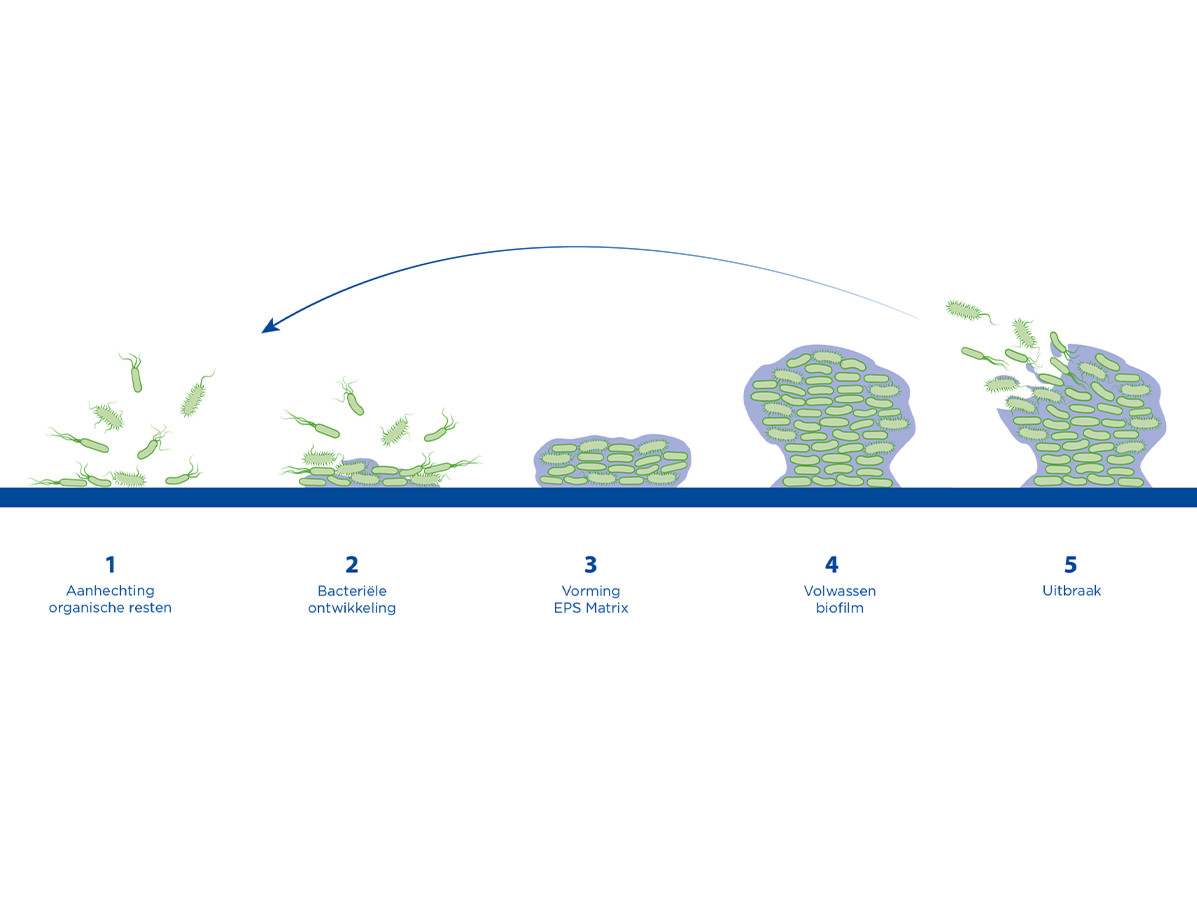

A biofilm arises because all kinds of bacteria and pathogens attach themselves to a surface and then protect themselves by developing an organic polymer layer. Maik: "See it as a bacterial settlement; the biofilm is the 'house'. As long as the door is closed and the bacteria 'stay inside', you don't notice a thing. With an Agar or swap control, you are measuring on the house, as it were. Therefore, you will not measure bacterial contamination."

Christeyns has developed a quick test to detect biofilm: TBF 300. This is a dye that in a few minutes attaches itself to the polymer layer of a biofilm. Maik: "We spray the foam on open stainless steel food contact points, let it soak in for five minutes and then rinse it off. Only where there is biofilm, you will see a pink discolouration. A biofilm audit must be carried out on a spotless stainless steel surface. This means that a thorough cleaning with alkaline cleaning agents must be carried out beforehand, followed by an additional acid cleaning. Finally, disinfection must be carried out. Then the surface should be completely free of organic and inorganic dirt and micro-organisms. After that, we can use TBF 300 to perform a biofilm audit on open stainless steel surfaces."

To remove a biofilm you must first break down the protective polymer layer, Maik explains. "You do that with enzyme-based cleaners. These are natural proteins. Enzymes convert such a polymer layer into water-soluble particles. The underlying bacteria that are then released are killed off with a double dose of disinfectant. We have developed a curative protocol to remove biofilm: a combination of enzymatic and conventional cleaning agents. After five to eight cleanings, the biofilm is gone. Then we check the same spots again with TBF 300 to demonstrate that the biofilm has disappeared."

A biofilm can always develop again. That is why Christeyns works with a preventive protocol of six months after the curative biofilm protocol. In this period, you just work with your conventional means of cleaning and once a week with enzymatic products to prevent any biofilm build-up. Maik: "During that period we carry out a biofilm audit three times to show that the biofilm is still gone."

It is sometimes thought that enzymes are dangerous. But that's not true, Maik emphasises. "They are even found in our saliva. Enzymes are pH neutral proteins, produced by fermentation and completely biodegradable. They destroy any organic matter and convert it into small water-soluble residues. Other bacteria convert these residues into natural components during the water purification process. Because enzymes speed up bacterial activity and purify wastewater, enzymatic cleaning is significantly better for the environment. An additional advantage is that they work at low temperatures of 40 to 50°C. We see enzymes as a complementary solution to the complex hygiene problems the food industry has to face. Besides the reduced risk of food contamination, enzymes also contribute to a sustainable policy."

The implementation of the biofilm protocol, including the audit to prove biofilm, is done under the guidance of Christeyns, says Maik. "The company itself carries out the cleaning steps, for which employees are first trained extensively. During the six-month preventive protocol, we take care of the interim audits and check the microbiological results together with the company's quality department. That is how we keep a close eye on everything together in order to keep biofilm at bay."

Source: Vakblad Voedingsindustrie 2021