Hygiene codes, HACCP, disinfection…when it comes to cleaning and hygiene, there’s nothing new to report. Or is there? We spoke to six experts about management systems for measuring and analysis, about enzymatic cleaning against biofilms, about a brand-new Food-related Cleaning course and about cleaning-conscious layout and design.

“Too many companies live from day to day and from audit to audit,” says Gert Visscher, Owner and Director of Eco2Clean, a supplier of cleaning and disinfection materials for the food industry. He’s immediately highlighted a challenge: laws and regulations are becoming ever-tighter and so too are checks on compliance. “An information management system can provide insight and help companies to not only react to incidents but also to make fundamental quality improvements and hence achieve cost savings.”

Gert Visscher continues: “For one of our major customers, analysis of all 200 inspection points in our information management system showed that 70 percent of all their deviations occurred on a specific type of conveyor belt. Extra disinfection and more thorough cleaning had little impact. Further research revealed the cause to be a new softening agent in the plastic used in the belt, which was more soluble in fats than the old version. Bacteria then formed in the resulting porous areas. When the belts were replaced by ones without plasticisers, the bacteria count dropped immediately.” Hago Food & Industry works with a software tool which supports the company in planning cleaning schedules, quality controls and safety checks. René Bakker, Account Manager at Hago (and a trained food technologist): “This helps us to work more efficiently and raises quality levels. Both the operator and the cleaner have insight into the process.” Another company that uses a digital system to monitor, analyse and safeguard food safety is Kleentec, cleaning specialist in the food industry. Managing Director Bas Niemeijer: “We ease the burden on our customers with Kleendesk. Analysis provides insight into the status of cleaning and hygiene, and that can form the basis for an action plan.” Yvette Kamps is Owner and Director of Special Cleaning Company: a young company based in Bunschoten specialised in industrial cleaning. She even goes so far as to say: “Providing cleaning as a standalone service is outdated. Nowadays, it’s about maintaining the hygiene status.”

There are important HR-related developments too. Changes to the Dutch Working Hours Act a couple of years ago have led to a number of challenges. Bas Niemeijer (Kleentec): “Since the amendments to the Working Hours Act, a permanent night shift is no longer allowed. Employers must offer a varied working pattern. That’s difficult for us because we do 80 percent of our work in the evenings and at night. Those are often the only times that production is at a standstill for a couple of hours. Moreover, most of our employees want to work nights because of the bonuses. We’re talking to our clients to develop new business cases. To ensure that the cleaning can still be done in the evenings, we’re looking at which other tasks can be performed during the day. I involve customers in that process. They tend to be understanding because we always deliver good performance.” René Bakker (Hago Food & Industry) faces the same challenge in the primary chain. “In other sectors there are cleaning techniques which enable the cleaning to be done during the day too – such as in bakeries, in the assembly industry and in dairy (baby food).”

It can be hard to find the right staff, says Yvette Kamps (Special Cleaning Company), “especially if you have high standards.” She consciously selects a mix of experienced workers and employees who still need to be trained. She provides much of the training herself: “I can let workers learn on the job at one of my customer’s premises...it serves as a training facility.”

Hago employs its own SVS instructors. SVS Opleidingen is a recognised training institute in the Dutch cleaning sector. René Bakker: “We run the Basic Training in Food-related Cleaning course for our employees and we also use the instructors to train our customers’ employees.”

Kleentec was one of the founders of the Basic Training in Food-related Cleaning. It worked together with SVS to develop the current version, which was launched recently. Kleentec itself takes a broad approach: “In the near future we will be launching a complete Level 2 MBO (vocational training) programme which starts with the Dutch language. That will be followed by the food-related training, VCA, techniques and equipment and, last but not least, customer awareness.” It’s a long-term, sustainable programme which demonstrates that the company is also thinking about the future. “We have very low staff turnover,” emphasises Bas Niemeijer.

So a cleaning company can make an indirect contribution to a food processing company’s CSR policy and the same holds true for suppliers. “Sustainable products and less harmful cleaning materials have been a trend for years,” says Gert Visscher (Eco2Clean). “Many of our customers opt for a mix of traditional products – which are cheaper to purchase – and biobased (organic) ones. Traditional materials don’t necessarily achieve cleaner results, by the way. Some biobased products are actually better,” comments Gert Visscher. “We offer all types of cleaning materials, plus relevant advice.”

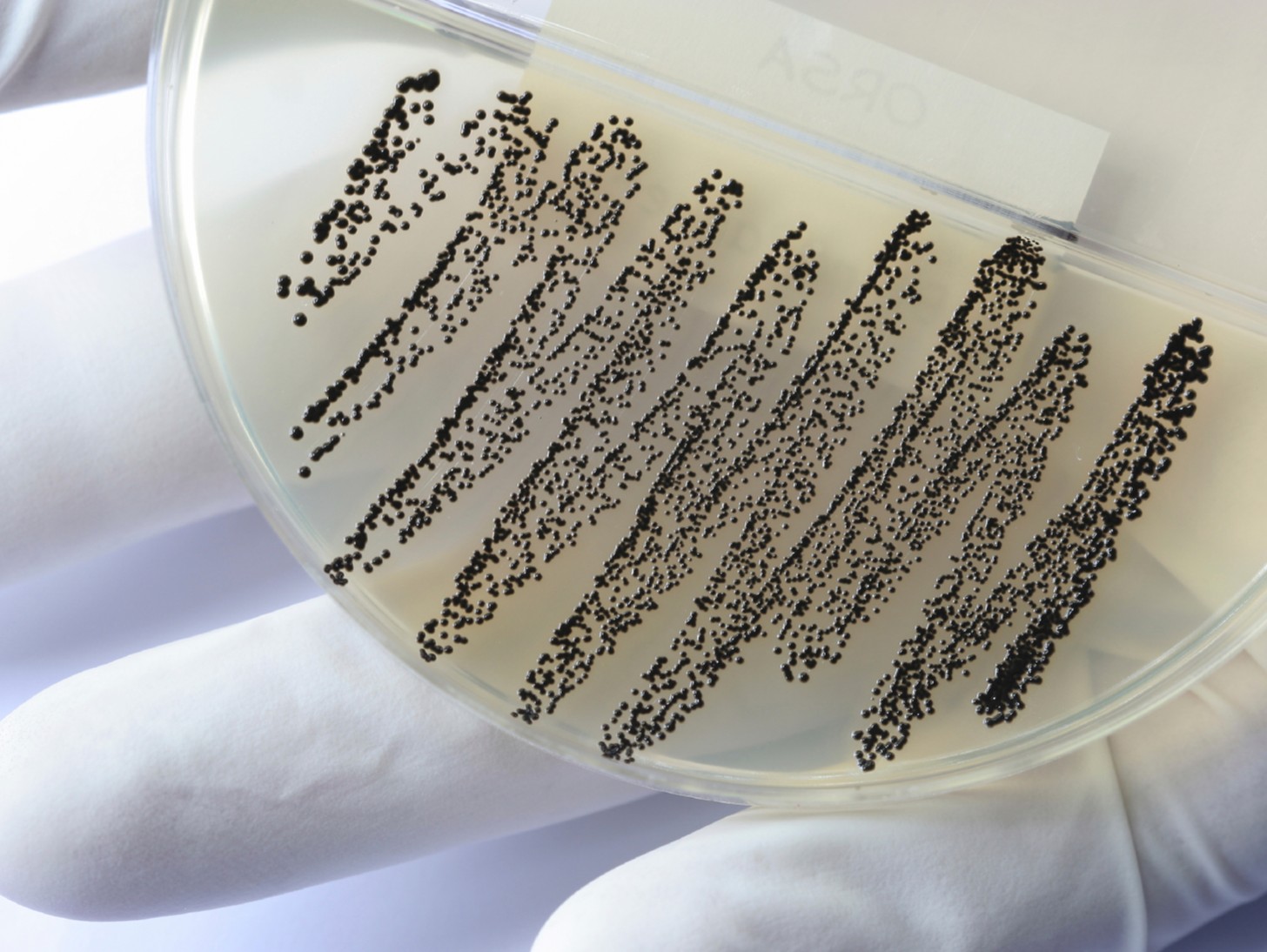

Eco2Clean is working together with a Belgian company on a new way of removing biofilms. “Biofilms are even more hazardous than we first thought,” says Visscher. “The microorganisms in a biofilm communicate by emitting signals to other microorganisms if it gets too warm or if cleaning occurs. Almost nothing is effective, not even aggressive cleaning agents. This increases the risk of a Listeria outbreak.”

The new technology is based on enzymes. “Enzymes break down biofilms. They work by destroying the film first so that you can use disinfection to tackle the microorganisms that are released.”

The increasing technological advancement of the cleaning industry is also demonstrated by a technique used by Yvette Kamps: nanocoating – “for putty,” she says. “That’s often the source of problems. Dirt can accumulate and bacteria begin to multiply along the edges. A nanocoating has a preventative effect. It inhibits bacteria before they have the chance to attach themselves to the surface.” Another tried and tested method is dry ice blasting. Bas Niemeijer: “Despite being labour-intensive, this is an effective method. It’s a problem solver. It’s a relatively expensive technique but sometimes it’s the only solution.” A new development is the addition of chlorine dioxide to the water that Kleentec uses for pressure washing. “We’re now testing this. Chlorine dioxide avoids the downside of aerosols and the steam that remains in a space after steam cleaning and which can still contain particles of dirt. Hence, this method helps to control Legionella, Salmonella and Listeria.” In addition to dry ice blasting, Hago also works with soda blasting, in which CO2 is replaced by sodium bicarbonate mixed with water. René Bakker: “Dirt rinses off more easily and it uses less water than traditional wet cleaning. Soda blasting is suitable for use in almost all industries except where dry cleaning is essential.”

As a result of tighter legislation and regulations, both nationally and internationally (e.g. BRC, IFS Food) certifying bodies such as the Netherlands Food and Consumer Product Safety Authority (NVWA) are not the only ones holding audits; it is becoming increasingly common for retailers to conduct their own checks too. Above all, they can turn up unannounced at any minute. René Bakker (Hago): “The total production chain and the food supply chain has become complex. The intended use of a product is not always clear, which is why customers’ wishes can sometimes appear over the top at first glance, but we have to take them into consideration.” “Any incident is always followed by extra measures,” notes Gert Visscher: “Tighter and more frequent checks. They’re often unnecessary, but they end up staying in the system afterwards. In other areas of the cleaning process there are never any problems, things always go well. Perhaps they offer an opportunity to cut back a little without compromising on quality. That’s how you can make some gains.” Many cleaning companies and suppliers of cleaning agents ease the burden on customers by using their systems to monitor hygiene. In that case, unexpected audits are no longer a cause for concern.

Last but not least, another aspect that deserves consideration is the design and layout of factories and production areas. Are the floors, walls and machines easily accessible, or does production have to stop before they can be cleaned? Are there any sills, ridges or gaps where dirt can gather? Awareness of a cleaning-conscious design is on the rise. René Bakker (Hago): “We’re increasingly being asked to think about a machine or production line in the design phase. For example, we are part of a working group alongside the likes of Bosch, Rittal, FrieslandCampina, Heineken and Gouda Holland to draw up better guidelines for hygienic design. One of the results has been a new cable tray without cable ties, for example.” Kleentec has also been approached to provide input into the layout and design of a factory. “Except,” comments Bas Niemeijer, “hardly any new factories are being built nowadays. They can be 25 years old or more, in which case you have to deal with the opportunities and limitations that you have.”

Vereniging Schoonmaak Research is a Dutch industry association of cleaning companies, suppliers and consultancy firms. The association conducts independent and scientific research into cleaning agents and methods. It published a document called Schoonmaakbewust ontwerpen voor de voedingsmiddelenindustrie – Handleiding voor de hygiëne en voedselveiligheid (Cleaning-conscious design for the food industry – a guide to hygiene and food safety) in 2010, and according to the organisation it remains relevant to this day. Anton Duisterwinkel, one of the authors, is a scientific journalist and has been involved in studies of cleaning methods and agents for many years. Along with Arnold Dijkstra, a food safety specialist, he wrote the recommendations. Anton Duisterwinkel: “This publication can help cleaning companies and manufacturers to enter into dialogue. For example, if you are a cleaning company you can say: ‘As long as these tiles are broken or this drain is rusty, I can’t clean effectively.’ The benefits: fewer risks of incidents and hence a damaged reputation; easier and hence cheaper cleaning; and better hygiene management. Isn’t that what every food manufacturer wants?”

Source: handenwassen: ©iStock.com/kokouu; petrischaaltjes: ©iStock.com/photoworldwide en ©iStock.com/Erdosain;