From high-quality extraction and processing of vegetable proteins to the production and cold storage of products, GEA has the specialist technology and experience. This is brought together in the New Food Team NL.

Alternative proteins have been on everyone’s lips for some time now – literally. The conscious consumer is demanding an alternative to meat and dairy drinks, (excellent sources of protein) driving the increased demand of alternative proteins for plant-based food and beverages.

But how do plant proteins get to our fridges?

The full extraction process typically begins with the flour obtained from beans or seeds for example, followed by wet processing, heat treatment and drying, with solutions integrated in the process for effluent treatment, including the reuse of water and heat.

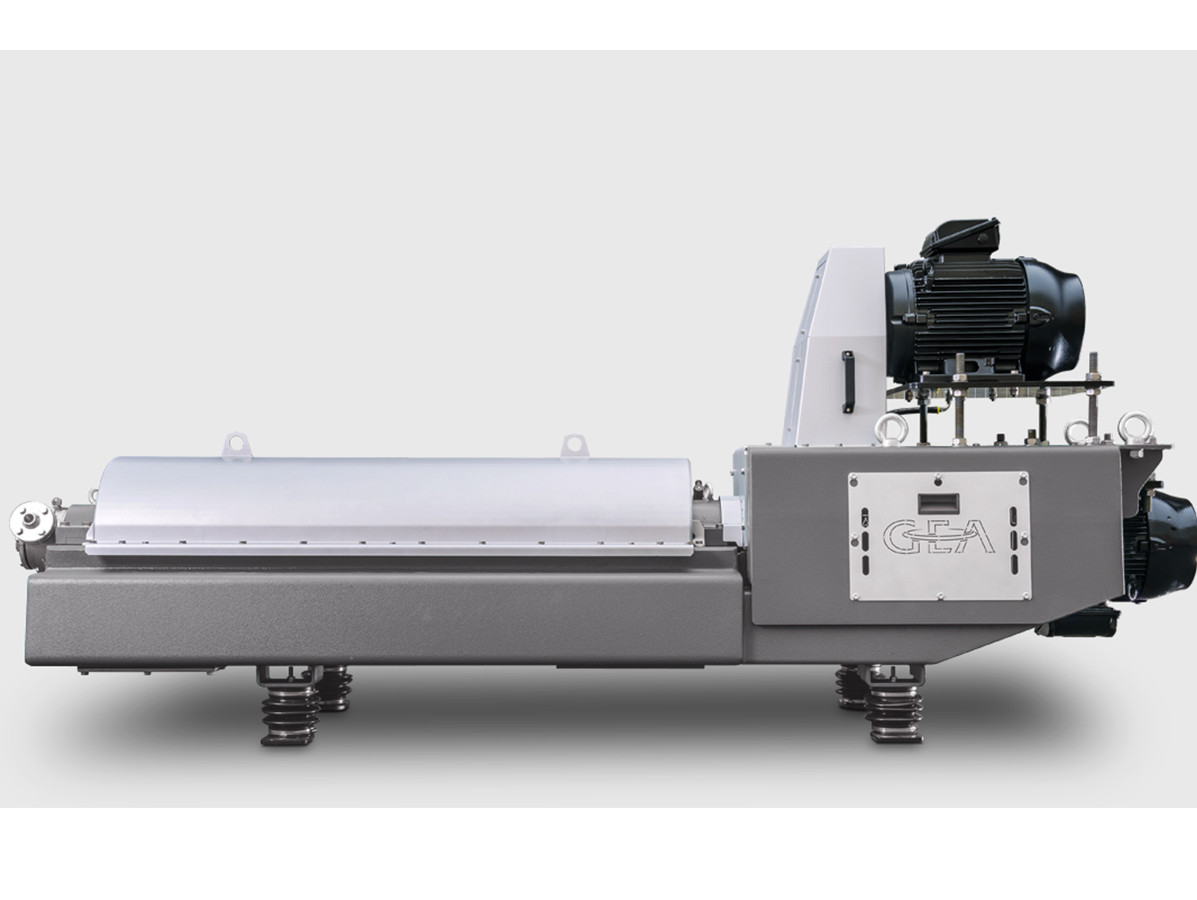

GEA offers complete processing solutions, including separators and decanters for extraction, concentration, washing and protein recovery. GEA experts have solved many of the common challenges associated with protein processing, like the GEA Varipond system to prevent foaming and yield loss.

A sustainable approach to the by-products after the protein has been extracted is not only important for the environment; it also opens additional income streams and cost savings of disposal. The protein taken out of a plant, whether it’s soy or pea, might be 25 percent, and the rest starch or oil. It is the right isolation and production of co-products from the side streams that adds to profitability.

GEA offers a wide range of spray dryers that can be configured to accommodate a broad spectrum of powder properties. With the 3D virtual test bench for spray dryers, GEA can simulate the behavior of the dryer systems already in the design stage and evaluate the consequences of design variations.

Through years of independent testing and close cooperation with its customers, GEA has developed tailored and task-specific end-to-end equipment and solutions for meat-replacement production. The equipment portfolio covers all production steps from mixing, grinding and cutting to forming, coating, heat treatment, freezing and sustainable packaging.

Test before you invest; Leave our test centers with your protein and product samples

Along with our diverse portfolio and industry-leading expertise, GEA offers well-developed pilot processes simulating the entire process. The ability to develop new products, applications and formulas before investing in new equipment and lines, greatly reduces the producer’s risk and accelerated go-to market. Our customers rely on our test centers and experts to ensure success and leave these pilots with protein and product samples generally suitable for pre-marketing. With the confidence knowing they will be able to achieve consistencies in yield, quality, efficiency and in machine and process performance in their own plants.

Do you also want to keep pace with the growing protein market? Meet our New Food Team NL and discuss directly with the experts the possibilities to reach the full potential of your opportunities.

More information: GEA New Food Team NL

Source: ©GEA