ViwateQ, developed by ViwateQ B.V., introduces a groundbreaking method for stainless steel surface treatment with its ViwateQ Finishing technology. The result of more than 20 years of research, this innovative approach offers unique advantages in hygiene and cleanability—particularly for sectors such as the food and pharmaceutical industries.

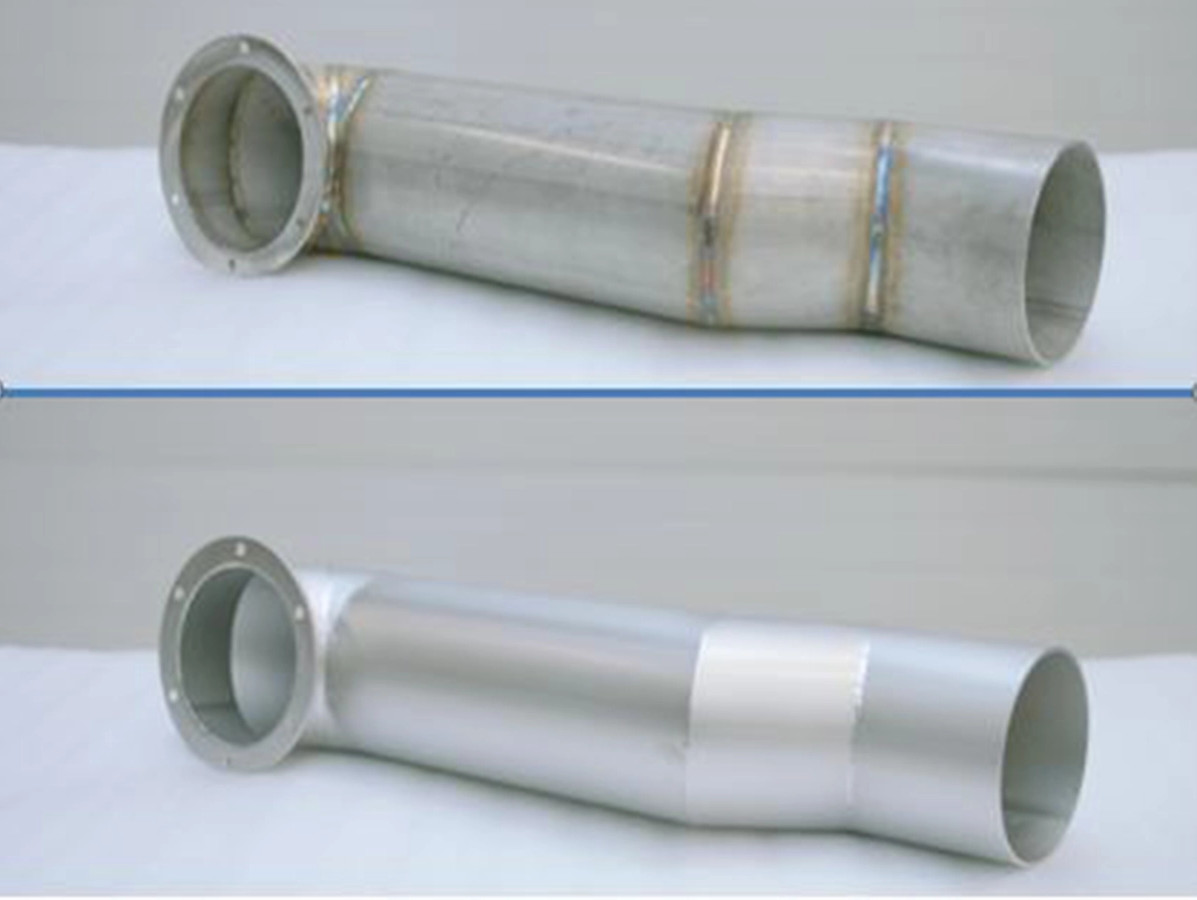

One of the key strengths of ViwateQ Finishing is its exceptional cleanability at the microbial level. Research by TNO has shown that stainless steel treated with this method is easier to clean compared to conventional surface treatments. The technology removes the oxide layer and unwanted contaminants, such as weld residues, without the use of chemicals. After treatment, a new oxide layer forms naturally through passivation, providing optimal corrosion resistance. The resulting surface structure minimises the adhesion of dirt, bacteria, and other microorganisms, significantly reducing the risk of bacterial contamination and under deposit attack.

ViwateQ Finishing also shortens cleaning times and improves cleaning performance, leading to increased production time and a safer end product. This is especially important in hygiene-sensitive environments, where downtime and contamination risks are costly. An additional benefit is the improved rolling resistance of dry substances, such as milk powder or sugar, which further increases production efficiency.

What truly sets this method apart is its environmental friendliness. Since no chemicals are required, ViwateQ Finishing has no negative impact on the environment and is safe for both humans and animals. This makes it not only a hygienic solution but also a sustainable one. In short, ViwateQ Finishing offers a combination of superior cleanability, hygiene, and ecological benefits, setting a new standard for stainless steel treatment in critical applications.

Food Tech Event 2025 | Hall 3 Booth 33

Source: Vakblad Voedingsindustrie 2025