While many fish companies in Urk are heading one way (towards salmon), Van der Lee Seafish prefers to go in the other direction (value-added products). A choice that has paid off well. With substantial growth in recent years, the time had come for both a renovation and a new refrigeration system.

“We have the best customers,” says the cheerful Willem van der Lee, co-owner of Van der Lee Seafish on Urk. He’s referring to major foodservice wholesalers, especially in Germany and the UK. “Not retailers constantly tightening the screws, but great partners who appreciate a good product, and value long-term relationships. We’ve been doing business with some clients for over forty years.”

Van der Lee Seafish has been around a bit longer than that. Back in 1973, Willem’s father Teun and his brother-in-law Jochem started a filleting company. For a long time, the focus was solely on fresh fish. But with mounting pressure on North Sea fisheries and declining catches, things began to shift. Willem: “Already thirty years ago, we started a breading line to add value to our fish. A breading machine, batter machine, forming machine, and oven to make fish sticks - that’s how it all started. It was a bold move at the time.” Today, roughly half of the 5,000 tons of fish brought in each year is processed: breaded, formed (into items like burgers), coated in batter and/or breadcrumbs, and usually pre-fried. “But we also produce chicken and vegetarian products. Sure, that’s a bit of an unconventional move on Urk. But our customers want it, and we know how to make it,” Willem adds.

Eric van Miltenburg (left) and Willem van der Lee

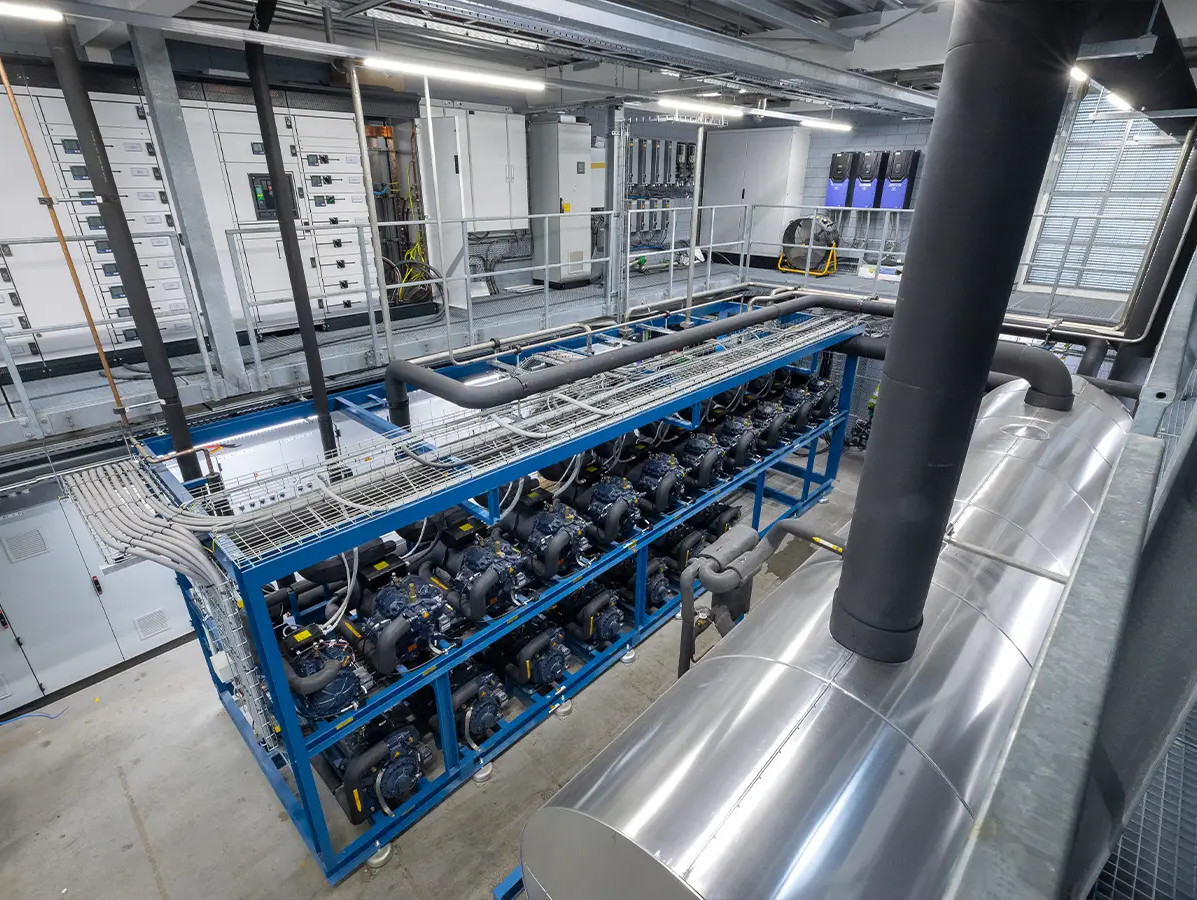

The other half of Van der Lee Seafish’s sales still consists of fresh fish. Partly from the North Sea (including plaice, dab, whiting, turbot, and razor clams), and partly from distant international sources. Nearly all products, whether value-added or fresh, are shipped out frozen. So when the company underwent renovations earlier this year - necessary due to growth - a new central refrigeration system was installed with high freezing capacity, including future compatibility with a thermal energy storage system. “Our existing R22, propane/CO2, and ammonia/CO2 systems needed replacing. We wanted a more energy-efficient unit that would also comply with changing regulations on refrigerants. Plus, we used to rely on a single large screw compressor. If it broke down, everything came to a standstill,” Willem explains. Eric van Miltenburg, account manager at Equans Refrigeration & Heating Solutions, adds: “The new system includes multiple small suction compressors that take turns running. If one fails, the others provide a built-in buffer.”

Another benefit of the new setup is improved efficiency. Willem: “Freezing time depends on outdoor temperatures and product thickness. A fish fillet takes ten minutes; a large sole takes a good twenty minutes.” Is the new system more energy-efficient? “We’re assuming so, but the bill hasn’t arrived yet,” Willem laughs. He’s worked with Equans for decades - through several name changes following acquisitions. “But the quality of their systems and service has stayed the same. We have complete trust in Equans. If something goes wrong, I just call and the technicians are at the premises in no time.” Equans supports food companies with solutions for today’s complex challenges. Eric: “Energy transition, digitalisation, increasingly complex regulations; there’s a lot to deal with. Meanwhile, food businesses are aiming for sustainable growth and need to stay operational throughout any transition.”

At Van der Lee Seafish, operations also had to keep running while the new system was being installed. It was done in a different location than the old ones. A reinforced floor was first constructed above the existing loading dock. “Super practical, because it allowed us to keep the old system running while installing the new one. In the end, the new installation was phased in over just two days,” Eric says. The new setup has enough capacity for all company freezers, including the new third spiral freezer. “We had to build upward for that. On Urk, there’s not much room for expansion, everything had to happen here,” Willem notes. Fortunately, he’s the kind of entrepreneur who prefers to look beyond the obvious path. It’s just part of who he is, he says: “Years ago, when North Sea fish supplies were drying up, most companies here had no choice but to switch to salmon. We didn’t; we doubled down on our value-added products. That turned out to be a smart move, because demand has only continued to grow.”

www.equansrefrigeration.nl

www.vanderleeseafish.nl

Photos: ©Koos Groenewold

Source: Vakblad Voedingsindustrie 2025