In the ongoing quest for sustainable alternatives to fossil fuels, TNO has pioneered an innovative method for large-scale production of clean biochar. The EnerChar method, based on biomass gasification, not only allows for customized carbon production but also generates heat and captures CO2 during the production process.

With the EnerChar method, waste residues from gardening, forestry, and the food industry are gasified on a grate, similar to waste incineration. This process yields clean biochar, serving as a sustainable alternative to fossil carbon. The generated heat and captured CO2 contribute to the environmental friendliness of the method.

The versatility of the EnerChar method opens doors to various applications. It can contribute to greening steel production by providing clean biochar, essential for making iron alloys. Additionally, TNO is exploring biochar production for batteries as a sustainable alternative to using natural graphite. In horticulture, biochar holds potential as an alternative to extensive peat excavation, with positive implications for the carbon balance.

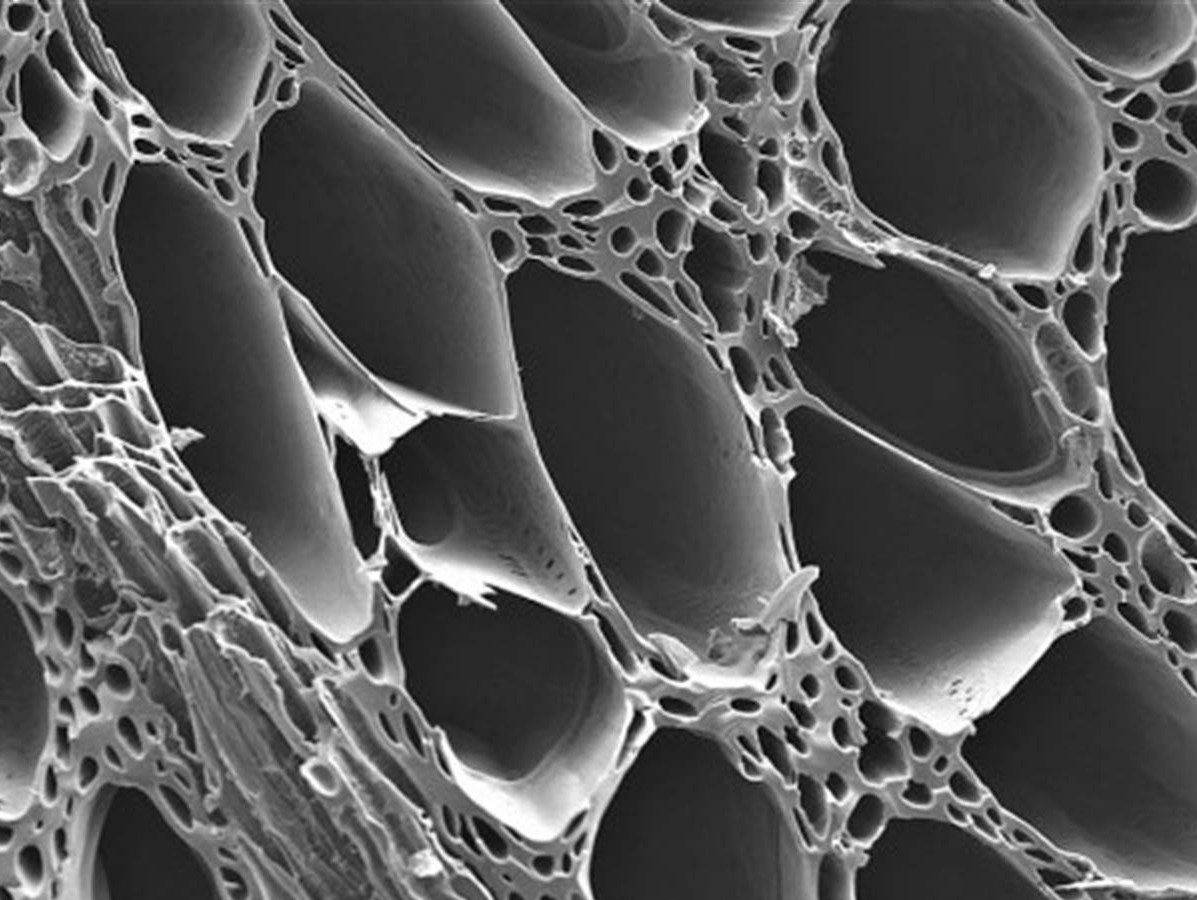

The unique aspect of the EnerChar method is its broad temperature range (350-850 degrees) and the flexibility to work with various gases, including air, steam, flue gas recirculation, and CO2. Through this variation, biochar of different qualities can be produced, suitable for diverse applications. The production process involves pyrolysis and gasification, where biomass is degassed, and the resulting solid residue, rich in carbon, possesses various properties. The resulting biochar can be lightweight, store water, and serve in purification processes, promising a substantial contribution to sustainability across various sectors.

Source: TNO