Everything can go without a hitch for years: low microbiological values, passing ATP tests with flying colours...until an unexpected outbreak of microorganisms occurs. This is a sign of the presence of biofilm, an invisible layer covering a build-up of microorganisms that can burst open. Luckily there is a way to detect, remove and prevent the formation of biofilm.

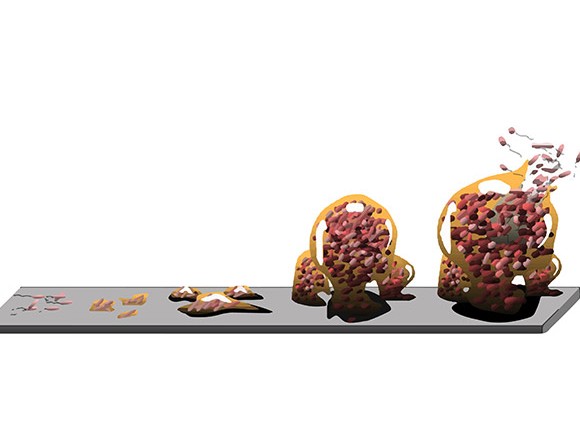

It is hard to believe that, despite all tests demonstrating good hygiene, a food manufacturing company can still be confronted with an outbreak of microorganisms. Yet that is the hidden danger of biofilm. Biofilm is formed when microorganisms adhere to a surface and secrete a polymeric compound that covers them with a protective layer. This layer is impervious to cleaning agents and disinfection. However, biofilm can suddenly open up and cause a higher concentration of microorganisms, despite good cleaning practices. Such an outbreak presents a threat to food safety, resulting in risks such as recalls and sometimes even serious calamities.

“The problem is, you can’t see it,” explains Leo Frings from Qlean-tec. Qlean-tec removes companies of the hygiene burden using self-developed cleaning products and tailor-made total concepts. In conjunction with a specialised partner, the company has recently started using a fluid to detect biofilm on surfaces.

“As far as I know we’re the only ones in the Netherlands who can directly and visibly detect on-surface biofilm. We spray the surface with a reactive liquid that changes colour. It only takes a couple of minutes. We find some form of biofilm or stubborn dirt – a potential breeding ground for biofilm – at virtually every company where we conduct a detection audit.”

The meat, fish and dairy sectors are particularly susceptible, says Frings: “Listeria bacteria are carried naturally by fish, and spoilage occurs rapidly in the meat and dairy industries too. Furthermore, a production process always has certain areas that are difficult for employees to reach when cleaning, despite EHEDG.” (Guidelines for the hygienic design and construction of equipment and spaces, based on the idea that microorganisms have the least possible chance to thrive, Ed.)

If you think that thorough cleaning and disinfection will prevent biofilm, you’re wrong. “In theory, biofilm can be prevented if every single part of the production process is cleaned and disinfected flawlessly,” says Frings. “But that’s virtually impossible. The human factor means that products or materials aren’t always used optimally.” Moreover, Frings has noticed that people often expect too much from disinfection. “They think: we’ve disinfected it so everything is okay. But disinfecting for just a minute less than necessary can leave behind huge numbers of organisms – well above safe levels. In fact, poor disinfection can even cause greater numbers of harmful bacteria to develop.”

As soon as Qlean-tec detects biofilm, it is important for it to be removed. That is done in line with a strict protocol. Frings: “Depending on the type of biofilm, we use a cocktail of enzymes. That enables us to penetrate the protective layer covering the microorganisms, which are then immediately removed in a cleaning and disinfection process.” There are many different types of enzymes. They break down organic contamination, such as proteins and fats, and convert them into smaller, water-soluble molecules. Frings believes that the standard application of enzymatic cleaning is the best approach to prevent the formation of biofilm: “Some companies are hesitant at first. After all, it means an additional step in the cleaning and disinfection process.”

Nevertheless, Frings is convinced that removing and then preventing the further formation of biofilm represents added value rather than an extra cost. “In order to supply to retailers, food manufacturers have to comply with very strict requirements. If you can prove that your products have lower germ counts than other products, then your products will also have a longer shelf life – and a longer shelf life means more profit for the retailer.”

Frings continues: “So by adding enzymatic cleaning to the cleaning and disinfection process, you don’t only prevent biofilm, but you also demonstrably improve the overall hygiene of your production environment and that leads to a better end product. That enables you to differentiate from your competitors and add value for your customers. Besides that, both the manufacturer and the retailer are at less risk of making negative headlines due to recalls.”

Now, you might be thinking, ‘This approach will involve more cleaning time, which means more production downtime’. But Frings puts things in perspective: “We advise manufacturers on their cleaning process as a whole. The parts that food products actually pass through are the essential areas. It’s practically impossible for food to become contaminated in other parts of the production area, yet those areas might currently receive just as much attention during cleaning. We work together with each client to analyse their production facility and we draw up an efficient cleaning plan that results in optimum hygiene for the customer.”

Source: © Qlean-tec