Shear cell technology offers the potential for a new generation of meat substitutes to be produced which are more closely aligned with consumer preferences in terms of their texture. This technology, which has been developed by Wageningen UR, is the first of its kind in the world. Through collaboration with the private sector, it is hoped that it will further extend The Netherlands’ lead as frontrunner in the field of meat substitutes.

Between now and 2050, the global demand for meat and meat products is expected to double. One way of meeting this growing demand sustainably is to develop meat substitutes that hold greater consumer appeal by resembling real meat more closely than today’s meat substitutes do. This resemblance is crucial: in order to persuade the majority of meat-eaters to switch to meat substitutes, it is essential to develop products that match real meat in terms of preparation, mouth feel and as an overall experience.

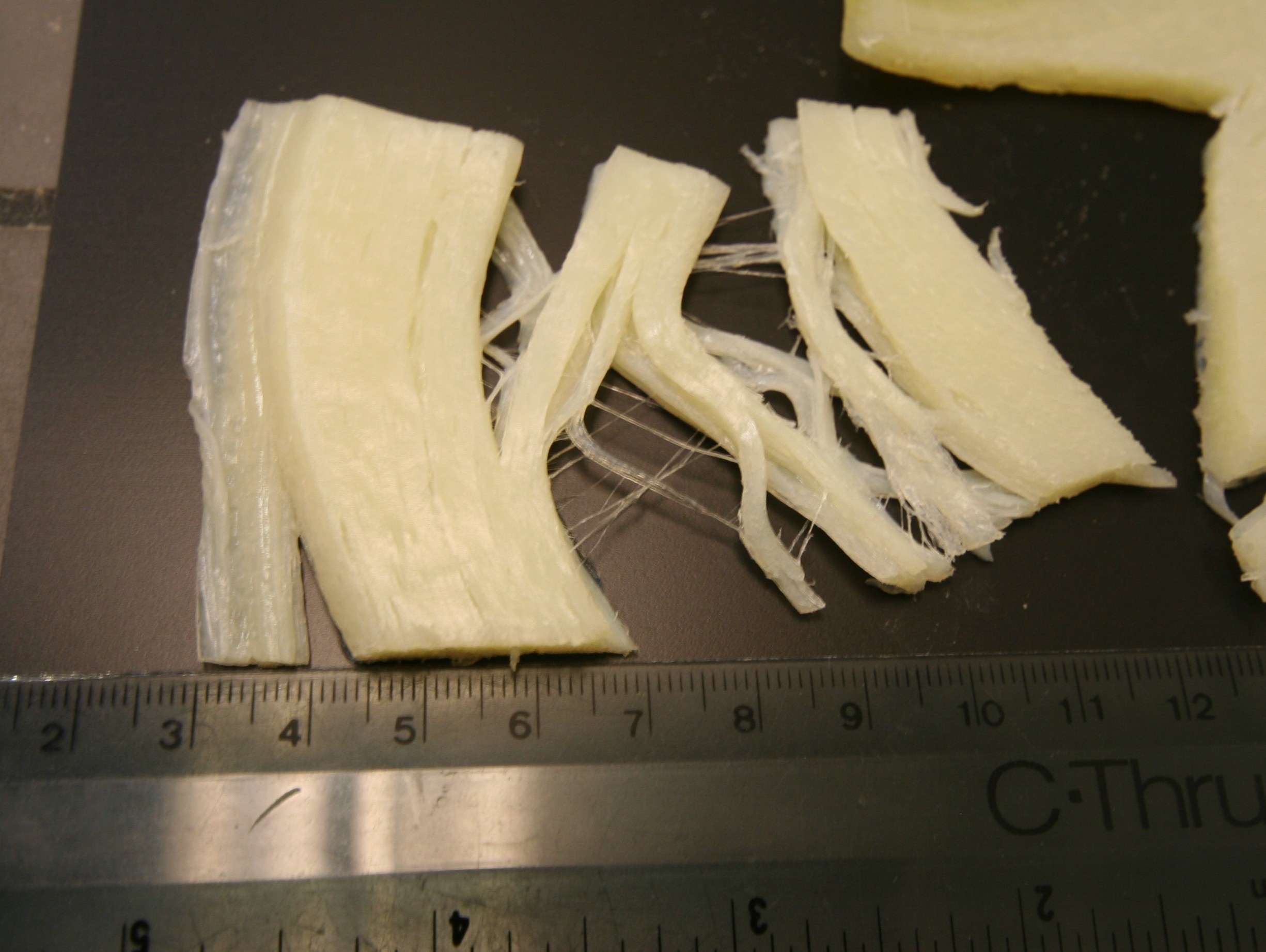

The current techniques produce meat substitutes which mimic the texture and bite of chicken meat. In recent years, the shear cell technology has been developed on a laboratory scale. This technology is able to create an even more fibrous texture and potentially ushers in a new generation of meat substitutes. The ‘proof of principle’ of the technological feasibility of the shear cell technology has already been provided: food technologist Atze Jan van der Goot and his team from Wageningen UR have demonstrated that this method enables various (plant-based) proteins to be used to form fibrous structures which display a clear hierarchical structure – and this is an important characteristic of meat texture. Both the fibre formation process and the length of the fibres can be regulated in a shear cell. This opens up opportunities for creating specific products for specific target groups. In order to do so, it is necessary to progress from fundamental research (development of the principle) to more applied research (development of the technology). Protein technologist Marcel Minor from Wageningen UR is supervising the scaling-up process whereby a distinction has been made between five user groups. That process should result in equipment for use in: 1) domestic households, 2) restaurants, 3) foodservice (e.g. healthcare), 4) specialised fresh food retail (e.g. butchers), and 5) the food industry.

Within the industrial/processing sector, it is a matter of enabling large-scale manufacture of meat substitutes. In addition to its textural properties, the shear cell appears to be an interesting alternative in terms of the amount of energy required in manufacturing: calculations have shown this is between 25 and 40% lower than when extrusion technology is used. Meanwhile, there appear to be only minimal differences between the two technologies with regard to water usage and product losses during cleaning. Therefore, in view of its environmental benefits (less energy and water consumption, and fewer product losses), the shear cell technology appears to score better than the current extrusion technology. Furthermore, the estimated investment costs for shear cell technology are considerably lower than those associated with extrusion.

Thanks to the limited amount of investment required, shear cell technology currently appears to be the only technology that is suitable for small-scale production of meat substitutes with improved fibrous texture. This unique benefit, in combination with the potential for better-quality products, can open up a new market segment focused on the small-scale, decentralised manufacture of meat substitutes.

This type of production offers the following advantages:

‘Shear cell technology: the potential basis for a new generation of meat substitutes’

In late 2013, work started on forming a consortium of companies and Wageningen UR, with the regional development agency Oost NV supervising the process. The parties involved all see added value in further developing and marketing small-scale applications. The aim is to launch equipment and ingredients on the market that enable end users to manufacture meat substitutes for their customers.

Any investors or companies who have ideas for interesting new applications for shear cell technology or for whom this innovative technology fits within their strategy are invited to contact Marcel Minor ([email protected]) or Jouke Kardolus ([email protected]).

References: Wageningen UR Food & Biobased Research report “Technologie voor het maken van een volgende generatie vleesvervangers: de shear cell technologie”, Remco Hamoen, Jeroen Knol, Johan Vereijken

Source: Wageningen Universiteit, Food & Biobased Research