Snijders Vleeswaren from Born is keen to stick to its traditional preparation methods, while the market is demanding healthier products with lower salt and fat contents. “That’s no easy task,” says the company director, Peter Francken. “But we’ve made great strides in recent years.”

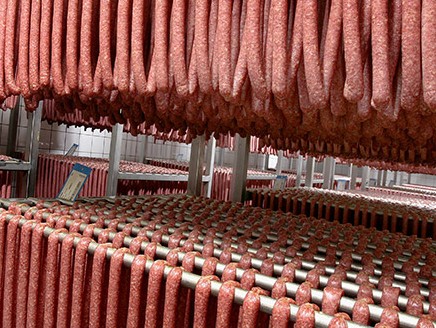

We are visiting Snijders Vleeswaren in the run-up to Carnival, and a major supermarket chain in Limburg has the salami on special offer, so it is all hands on deck for the employees to ramp up production.

Peter Francken demonstrates that the company’s cured sausage is still produced in the traditional manner to this day. The raw meat goes into a cutter and the herbs are subsequently added. The meat is then cured and smoked. “We manufacture on a large scale, so many of the steps are computer-controlled. For instance, the cutter indicates the exact moment that the herbs must be added, and in which quantities. But nothing has changed in terms of the preparation method. We still smoke the meat using real beechwood, for example. We won’t compromise on that.”

Health is a key topic for Snijders Vleeswaren and the company has been working to reduce fat and salt levels for years. “Initially, we wanted to be allowed to display the ‘Ik kies bewust’ (‘Choices Programme’) logo on our products. Nowadays virtually all the food retailers are demanding healthier products.” Peter explains that reducing salt is particularly difficult. “Salt is what gives cured sausage its flavour. Even a tiny reduction in the salt level causes a loss of flavour. Consumers can taste the difference. Furthermore, salt gives cured sausage its long shelf life.” Snijders made significant progress by replacing regular salt with OneGrain mineral salt, but that did not go far enough for the company so it also redesigned some of its processes. “For example, you can smoke sausage for longer to extend the shelf life,” explains Peter. “But what does that do to the flavour? Which changes could be made to the formulation? And what consequences will that have for mixing? The trick is to play around with all the different values and to experiment a lot. In the end, you arrive at tasty products with a considerably lower salt and nitrite content.”

‘Nowadays virtually all the food retailers are demanding healthier products’

Fat reduction is another important topic, but Peter regards that as less challenging because fat has no impact on the shelf life. Its primary function is to make products tasty and inexpensive. To reduce fat, Peter has likewise adapted the processes to ensure that consumers cannot taste the difference. “But the most important factor is that we always use high-quality meat,” he says. “We work with local pig farmers who are ‘Milieukeur’ (‘Environmental Mark’) or ‘Beter Leven’ (‘Better Life’) certified. Hence the pigs have been reared in animal-friendly conditions with consideration of aspects such as more space and natural light in the stalls and toys for them to play with. The farmers don’t use of antibiotics preventively either. As a result, the meat tastes better plus you need less fat.”

Peter explains that the company is facing new challenges in the years ahead. “The market is developing all the time and we want to stay at the forefront.” Hence, Peter intends to further reduce the salt percentage, and he sees other trends too. Some of the sausages are currently sold in plastic film, “But many retail customers would rather display the sausages in their stores without film wrapping. On the other hand consumers want a long shelf life, so we’re looking for a satisfactory compromise.

Additionally, Peter is seeing a growing demand for pure, natural ingredients. “We’ve always considered it important to use pure herbs. Chemical additives are not a good fit with our company, which is why we use as few E-numbers as possible and we’re continually looking for natural alternatives. Consumers are placing greater value on that.” Peter has also noticed that the Milieukeur and Beter Leven quality marks are becoming increasingly important to retailers. “That’s a good match with our philosophy,” adds Peter. “So we will be able to meet that growing expectation in the future.”

‘Lekker uit Limburg’ (‘Flavour from Limburg’) is a Vers Logistiek Limburg BV (VLL) brand. VLL is a fresh-logistics joint venture between Keulen Vleeswaren from Nuth and Snijders Vleeswaren from Born.

Under the Lekker uit Limburg brand, they jointly present a product range comprising a selection of artisan meat products and other specialities. Thanks to its unique brand image, Lekker uit Limburg has since evolved into a recognisable and valued mark of quality on the shelves of leading food retailers nationwide.

Photo: Company director Peter Francken

Source: Snijders Vleeswaren