In the food industry, hygiene is inextricably linked to food safety. Food safety is a hot topic, which means that cleaning and disinfection is too. Here, experts highlight the most important trends: the broadening and deepening of services, the perception of cleanliness, digitisation, robotisation and sustainability.

Most companies in the food industry outsource the cleaning of their premises and production areas to external cleaning specialists. What are the most recent developments in the cleaning sector? And what do they mean for the food industry? The answers to those questions are provided by Rabobank, which published the latest ‘Figures & Trends’ report for the cleaning sector last month, and by René Bakker from Hago Food & Industry and Wouter Burggraaf from Burggraaf & Partners (independent consultancy firm specialised in hygienic design for food, feed and pharma) who analyse the implications of these figures and trends for the food industry.

Trend 1. ‘Broadening and deepening of services’

The blurring of the boundaries in food retail is starting to affect the cleaning sector: “The sector is experiencing increased competition due to the growing number of companies,” notes Rabobank. “New market entrants from outside the sector, such as security companies, painters and caterers, are creating extra price pressure and the need to be distinctive. More and more customers regard cleaning as a commodity – a bulk product, the price of which is determined purely by supply and demand.” René Bakker: “Customers’ wants and needs are becoming broader yet more specific at the same time. They are asking for ever-more efficiency, quality and involvement. They increasingly want a single supplier to take care of everything and fully relieve them of the burden.”

Rabobank primarily sees evidence of the broadening among the larger cleaning companies, which besides cleaning are increasingly taking care of minor maintenance (such as changing light bulbs and locks), catering, gate-keeping and gardening tasks. But there is also a deepening of the service offering, especially in the food industry where the requirements are very specific. René: “Companies are taking a critical view of the costs and looking for ways to increase their efficiency, yet without compromising on safety and while also maintaining the same quality level. The food industry is aware of the risks, now more than ever before. Specialist knowledge and experience in cleaning and disinfection in the food industry are essential in safeguarding the quality and food safety.”

In recent years, the food industry has embraced the concept of corporate social responsibility (CSR). Although other industrial sectors have been progressing towards greater sustainability and new business models for some time, CSR has now become commonplace in the food sector too. “Cleaning efficiency is also part of that; it’s got to be right first time and losses must be minimised.” Through improvement programmes such as ‘lean’ and the focus on ‘autonomous maintenance’, he is seeing that companies are once again handling some cleaning activities themselves. “That’s only logical, because the machinery is becoming more complex all the time. The operator is the specialist; he knows his own production line inside out, carries out minor repairs and also keeps the machine (and its components) clean. At the same time, there is immense pressure to reduce downtime, making (cleaning) support necessary during stops to enable the equipment to be started up responsibly. So we need each other now more than ever.”

Trend 2. Society is digitising so the cleaning sector is too.

“We organise the complete cleaning process for specific projects based on sector-specific management systems,” says René. “Our vakmansch@pp software tool, which has been developed in conjunction with the software company LEVIY, enables the further improvement of internal work processes. On the one hand it’s used to digitally ensure checks and process the cleaning results, and on the other it improves the planning efficiency and registers any deviations and calamities. There’s an app for the smartphone or tablet and also an online portal. The customer uses the tool to keep us informed, such as about when the line will be stopped so that we can clean. Both sides have real-time insight into the number of hours worked and which areas have been cleaned.”

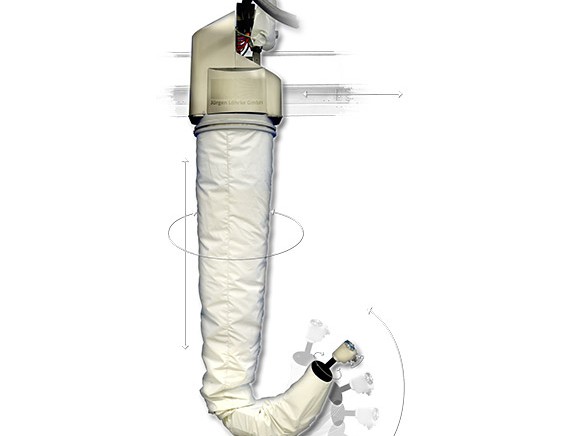

But that’s not all: “Robotic Cleaning in Place, or in other words r-CIP, is the future,” states Wouter Burggraaf. “Not only does this enable you to save on the total cleaning costs and downtime, but it’s also the only way to be able to guarantee that you can start with clean equipment. Cleaning a production line manually can easily make an adjacent, just-cleaned one dirty again. In r-Cip, the spraying is very targeted which prevents cross-contamination. Furthermore, r-CIP is reproducible and can therefore be validated.”

Trend 3: Cleaning is increasingly being assessed based on the perceived cleanliness, sector-wide.

“When measuring the results of cleaning, not only the quality is considered but also the perceived cleanliness,” claims the Rabobank Figures & Trends report. “At the same time, daytime cleaning is gaining in popularity. The advantage is that the cleaner is becoming more visible, can assume a role of host/hostess and is getting more closely involved with the organisation that he/she is cleaning.” “This works in the same way in the production environment,” says René, “except when it comes to ensuring food safety, the perceived cleanliness that Rabobank refers to won’t get us very far. Our contribution to quality and safety must be mentioned in the same breath as the perception of cleanliness.”

“Daytime cleaning offers more advantages,” says Wouter, who recently witnessed an evening cleaning session up close in relation to a case of microbial contamination. “After all, it’s tremendously tiring to have to stay alert when cleaning at night. It’s easier to keep the production up and running at night than to clean manually. I recorded some video footage and showed it to the board of directors. They reached the same conclusion, namely that it’s better to move the cleaning activities to the daytime shift.”

Trend 4: The cleaning sector is investing in sustainability

The food processing industry is becoming increasingly environmentally aware, and the resources used in the sector also have to be aligned with that. René: “We’re seeing cleaning materials becoming increasingly biodegradable and the cleaning methods are better for the environment in every sense, including in terms of saving energy and reducing water consumption. In my view, the application of innovative methods and materials is an essential step towards more sustainable production. Another thing that is at least as important is that employees are aware of their behaviour and how they can help. We all share the responsibility for making life easier for the cleaner, both through effective and hygienically designed machines and production areas and by using optimal cleaning techniques and products. That’s how cleaning can contribute to better food safety.”

“It’s true that sustainability goes hand in hand with smart design,” adds Wouter. “Hygienic design demands accessibility and good seals to enable cleaning at microbial level. Combined with special spray heads, such as Undine, it’s possible to achieve water savings of up to 70% – while guaranteeing the cleanliness of the system. The challenge lies in no longer regarding cleaning as an afterthought, but rather as one of the prerequisites for functional design. We’ve risen to that challenge in recent factory designs and have integrated the machines into walls and floors. You only need to clean the surfaces that can get dirty. That generates lots of savings – in terms of time, chemicals and energy, not to mention maintenance. Meanwhile, you also have more uptime and no product losses. That’s when you’re talking about real sustainability,” he concludes.

Course

The two-day ‘CIP with innovative cleaning techniques’ course on 6 and 7 April 2017 will cover the entire range of new, automated cleaning systems, from the automatic cleaning of pipes and tanks to the cleaning of open systems such as conveyors, fillers and other equipment.

In collaboration with SafeFoodFactory, EHEDG Netherlands is organising the ‘Product recovery – a forgotten step in CIP’ seminar on 16 February 2017 in Raamsdonksveer.

www.burggraaf.cc

www.safefoodfactory.com

Source: ©Lohrke