Avocados require smooth processing due to their rapid discolouration. If that process is partly manual, the machine part cannot fail. A tamper-proof sealing machine is then indispensable.

"No party in America without dips. In America, they often use the term lazy foods for dips and finger food," says Ron van der Vloed, when asked about the origin of the name of his company. During his visits to the United States, he frequently came across chilled guacamole in the supermarket shelves. " Over here I merely saw the frozen version with preservatives," he says. "So in 2015, after many years in the fruit and vegetable industry, I decided to take a leap. I've seen the popularity of avocados grow and I'm a big fan of healthy, fresh food myself," explains the founder and owner of Lazy Foods. The leap turned out to be a success: Van der Vloed can now count domestic and foreign (European) retailers and food service companies among his customers. He sells both private label and Lazy Lizard products to these customers. Turnover has been growing every year since the company was founded. With approximately 5 permanent employees and 20 to 25 temporary workers, pallets full of guacamole, tomato salsa and various types of hummus leave the factory in Ridderkerk every day. The mashed avocados without additives, which Lazy Foods frequently produces and which are used by customers as a basis for spreads, among other things, are also popular with the foodservice sector.

The avocados come from a different region each season: Chile, Peru, South Africa, Colombia and Spain. Van der Vloed: "We have direct contact with the growers, but are also assisted by an importer in some cases. A nice fact: the Netherlands is the world's second largest exporter of avocados, even though no avocados are grown here. ”

The number of avocados that are processed each week at Lazy Foods is not mentioned by Van der Vloed, nor how the production process works. "We're being watched a lot," he winks. Part of the success formula lies in the way the product is processed and packaged and in the application of the mild preservation technique, the High Pressure Processing method (HPP). With this method the closed, packaged products are put under high water pressure, up to 6000 bar. Van der Vloed: " This prevents bacteria and fungi from developing and our products retain their original fresh taste and vitamins. Thanks to the HPP technique, the bacterial shelf life of our product is 50 days - the sensory shelf life is 45 days. The HPP process requires extra steps, which make the process more expensive. However, this is the only way we can stick to the principle of not using preservatives or freezing. All our products are 100% natural. Usually, guacamole uses a lot of citric acid to extend its shelf life. For us, this is not the case. This also means that our guacamole cannot be stored for long after the container has been opened because the product discolours after a while. But it underlines the honesty of our product".

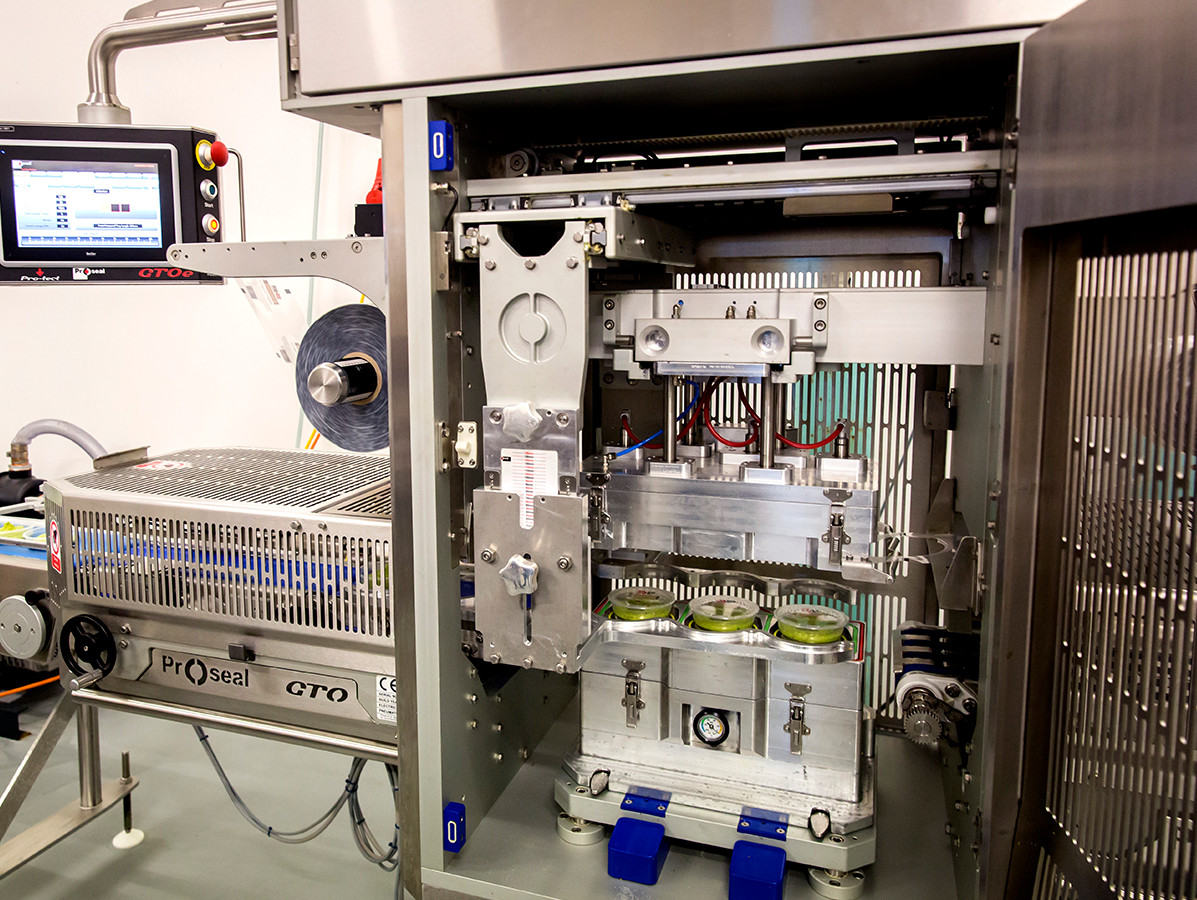

And because the avocado - according to Van der Vloed a "beautiful but difficult product" - discolours quickly, speed is required in the production process. "The avocados are halved and then peeled by hand. They are then mashed by machine, mixed with other ingredients, weighed and packed. The whole process takes about 20 minutes. Reliable machines are therefore also essential in production," he says. To seal the guacamole and other products, the entrepreneur chose the Proseal GT0-e from Sismatec in Almelo in 2015. This sealing machine can be used to pack MAP trays. Other products are only sealed without vacuum or gas. Van der Vloed explains his choice: "One of our neighbours, also a food company, had positive experiences with Sismatec. I approached them and they became involved with us right from the start. They also contributed to the design of the production area and the routing. And still today, now that we are thinking about an expansion, they help us with advice. Even if that's not part of buying machines. They think along with us in the overall process."

This extra service is pleasant, but in the end it is Van der Vloed's job to provide the operational reliability that Sismatec offers. "The machine does not stop at any time. Never, really. Well, maybe the last time when our employees didn't fasten a tooling properly and a spring had jumped. All you have to do is call them and they're already on their way. They're well distributed nationwide, so in a couple of hours we were up and running again."

www.sismatec.nl

www.lazyfoods.eu

Photos: © Dennis Wisse - Roel Dijkstra Fotografie

Source: © Vakblad Voedingsindustrie 2020