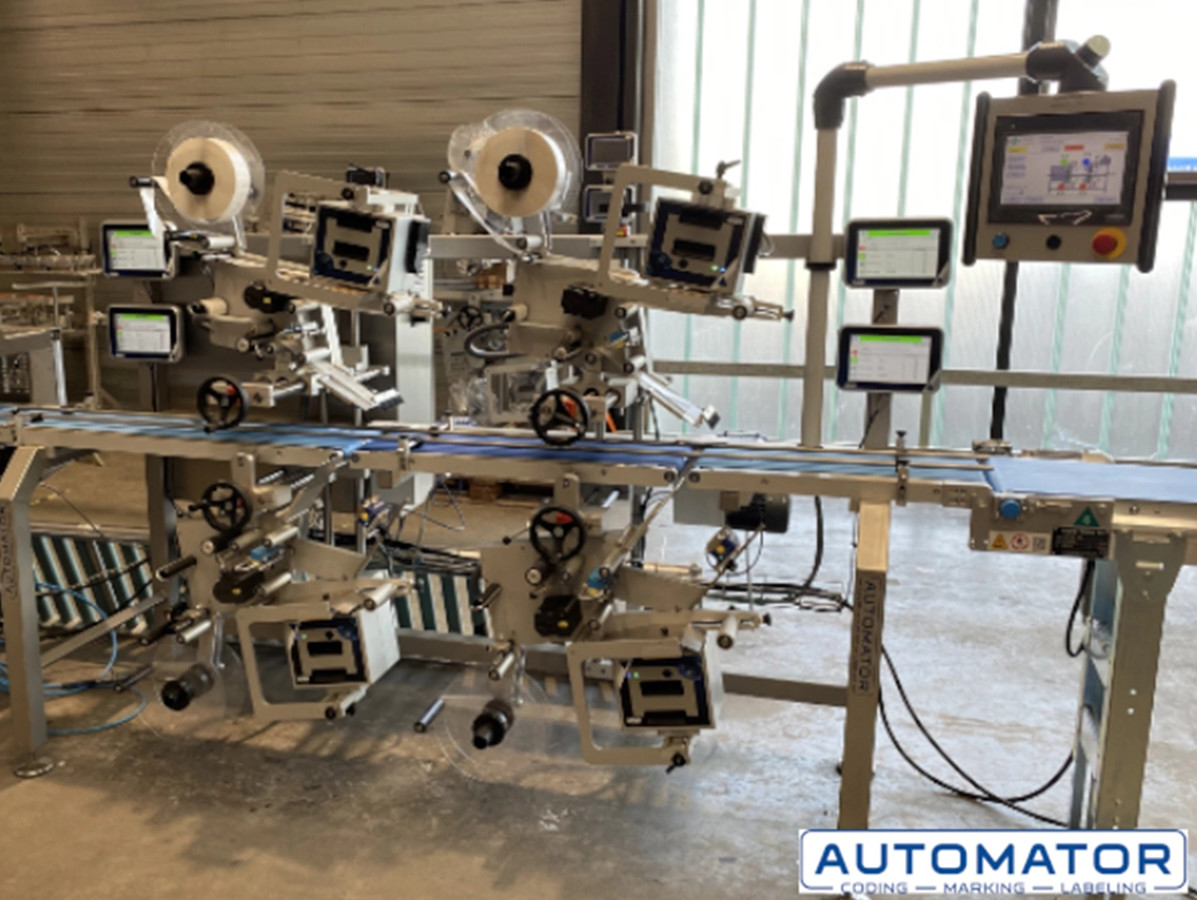

The EME 5000 labelling machines are equipped with the latest technology, featuring an Omron Sysmac PLC controller and high-performance servomotors. They meet the highest standards for speed, precision, and ease of use. The powerful, low-noise servomotor ensures highly accurate label dispensing, while the user-friendly display provides access to all functions.

Easy to operate

Product-specific settings

Real-time insights

Flexible production modes

Optional features

The EME 5000 labelling machines come in various sizes and are available in both left- and right-handed models. Several mounting systems are available, allowing labels to be applied from the top, side, or bottom.

Wondering which solution best fits your needs? Our team is happy to help you choose the model that aligns perfectly with your production processes. Feel free to contact us for a no-obligation consultation.

Email us at [email protected] or call +31 (0)10 415 64 00.

www.automator.nl

Source: Automator