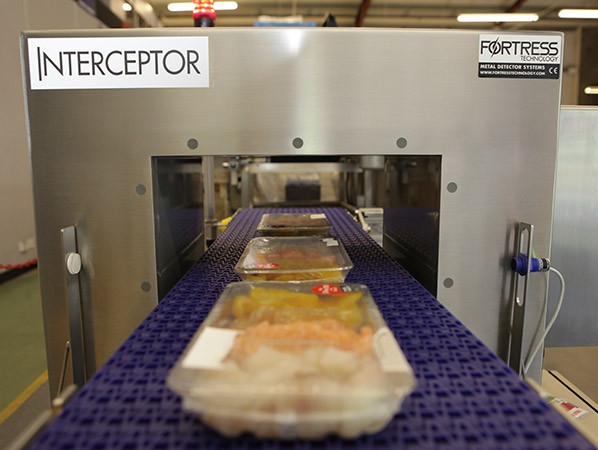

The Interceptor metal detector launched by Fortress Technology and on show at IFFA 2019 (Hall 11, Stand 11.1.C71) is taking wet food inspection to a new level of sensitivity.

Conquering the longstanding challenge of ‘product effect’ caused by moisture and minerals, the Interceptor is specifically designed to inspect conductive applications, including meat, poultry and seafood, cheese, desserts, ready meals, bakery items and fortified cereals, helping to eliminate false rejects.

This revolutionary operation facilitates an improvement in detection capabilities of up to 100% with stainless steel, especially when inspecting traditionally difficult ‘wet’ products or using metallised film during processing. In real terms, halving the test sample sphere size to 0.5mm equates to picking up a wire length contaminant of 25mm.

Rather than tuning into specific frequencies, the Interceptor cuts out background interference caused by product effect, tackling the issue of false positive readings in wet and conductive products that lead to high product rejects. By splitting and simultaneously analysing the low frequency and high frequency signal, the Interceptor can clearly differentiate between the signal generated by the product as a result of moisture or mineral content (for example salt that’s prevalent in bacon) and any metal contaminant. The result is a more reliable and accurate reading regardless of size, shape and orientation of metal particles.

Interceptor units can be deployed in different locations on the production and packing line, including apertures customised to a given conveyor, pipeline configurations for pumped product applications, such as sausage meat, or gravity systems for powders.

For ease of use, the Interceptor learns and recalls the signature of any given product with just one pass. FM Software is integrated, bringing a predictive element to the analysis of signals from the metal detector.

Customers can choose either Wi-Fi or Ethernet connections for easy and accurate data collection. To reduce the risk of human error when manually testing the performance of the detection system, Halo automatic testing can be added.

Standing by the company’s ‘Never Obsolete’ commitment, customers with an existing Fortress metal detector can easily upgrade to the very latest processing unit and software.

Being IP69K rated, the Interceptor range is resistant to water ingress and dust, ensuring long-term reliability and performance in heavy processing and washdown environments, for example bakeries, meat and seafood plants.

Moving ever closer to the performance of x-ray but at a much lower capital investment, the Interceptor also reliably detects the range of ferrous and non-ferrous metals, including aluminium. For bulk meat cuts or cheese products, where variations in density pose a challenge to x-ray, the Interceptor is the only sure option for the detection of metal contaminant.

“The combination of 100% increased metal detection sensitivity, reduced false product rejects, single pass product learning, and straightforward upgrades go a long way to boosting overall equipment effectiveness and quality assurance for food processors and manufacturers, as well as safeguarding consumers,” highlights Fortress Technology’s European Managing Director, Phil Brown.

Source: © Fortress Technology