Evaporators in the cooling, freezing, and production areas of the food industry pose an underestimated contamination risk. These systems, which cool and circulate air, may appear clean from the outside but are often contaminated on the inside, serving as a breeding ground for microorganisms such as Listeria, which can survive in cold conditions. The risks are particularly high in spaces where unpackaged, ready-to-eat products are processed.

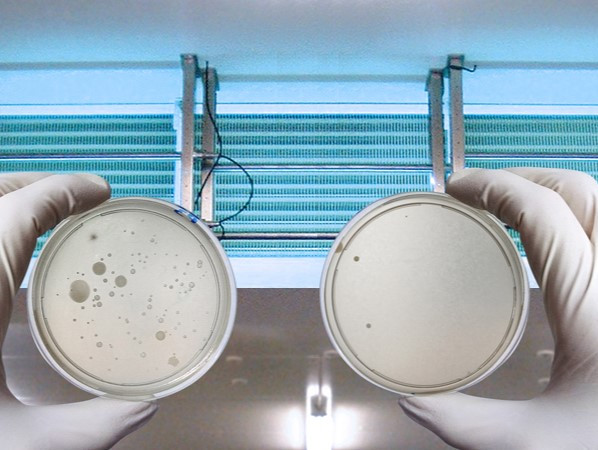

The fins and drip pans of evaporators can become coated with a slimy layer of biofilm, where bacteria can establish and multiply. This can lead to product contamination through condensation droplets that fall onto the food or through the airborne spread of bacteria. Even well-intentioned but improperly executed cleaning actions with high-pressure cleaners can exacerbate the problem by dispersing bacteria throughout the area. Bioclimatic offers a solution in the form of UVC lamps that can be installed in or in front of evaporators. UVC light damages the DNA of microorganisms and prevents them from multiplying, without the risk of resistance. This turns evaporators into a means of air purification, reduces the risk of contamination, and decreases the frequency of cleaning.

The food-safe UVC fixtures and lamps used by Bioclimatic are waterproof and corrosion-resistant. By continuously treating evaporators with UVC light, biofilm is prevented, which not only improves hygiene but also enhances the energy efficiency of the cooling systems.

Learn more on the Bioclimatic website

Source: Bioclimatic